If you’ve ever tried flux core welding, you probably know how frustrating spatter can be. Those little bits of molten metal that fly off during the welding process not only make a mess, but they can also interfere with the quality of your weld. I’ve been there, cleaning up more than I bargained for after a session of flux core welding.

I’ve learned a few effective techniques to reduce spatter and improve weld quality. In this article, I’ll walk you through practical steps to minimize spatter, explain why it happens, and share tips that have made my welding process smoother and cleaner.

What Causes Spatter in Flux Core Welding?

Spatter is the result of molten metal droplets being expelled from the weld pool. This happens for a variety of reasons, including improper settings, technique, and material preparation. Here are some common culprits:

- Incorrect Voltage or Amperage Settings: When your machine isn’t set correctly, it can cause unstable arcs and lead to more spatter.

- Poor Technique: Inconsistent travel speed or the wrong gun angle can create unnecessary spatter.

- Dirty or Contaminated Surface: Dirt, rust, or oil on the base metal can disrupt the welding process.

- Wire Quality: Using low-quality or improperly stored flux core wire can increase spatter.

Understanding these causes is the first step in reducing spatter. Let’s dive into how to fix these issues.

How to Reduce Spatter When Flux Core Welding

Fine-Tune Your Welding Machine Settings

Getting your machine settings just right is crucial for minimizing spatter.

- Voltage: Too high or too low voltage can create arc instability, leading to more spatter. Adjust your voltage based on the thickness of the material and the wire you’re using.

- Amperage: Ensure the amperage matches the wire feed speed. A mismatch can cause irregular arc performance and result in excessive spatter.

- Wire Feed Speed: Start with the recommended wire feed speed and adjust as needed. A speed that’s too high or too low can make the weld unstable.

Take time to test different settings on scrap metal before starting your project. This simple step can save you hours of cleanup later.

Use High-Quality Flux Core Wire

The quality of your welding wire plays a big role in how much spatter you’ll deal with. Cheap wires often contain impurities or inconsistent flux, which can lead to more spatter.

When choosing flux core wire:

- Opt for trusted brands that provide consistent quality.

- Check that the wire is appropriate for your specific application and material type.

- Store your wire in a dry, clean environment to prevent moisture absorption, which can lead to weld defects.

Clean the Base Metal Thoroughly

Dirt, rust, and oil on the base metal can cause spatter. Before you start welding, take time to clean the surface properly.

- Use a wire brush or grinder to remove rust and dirt.

- Wipe the surface with a degreaser or acetone to eliminate oils.

- Ensure the surface is dry before welding to avoid reactions with moisture.

A clean surface not only reduces spatter but also improves weld penetration and strength.

Improve Your Welding Technique

Your technique can significantly impact the amount of spatter you produce. Here’s what to focus on:

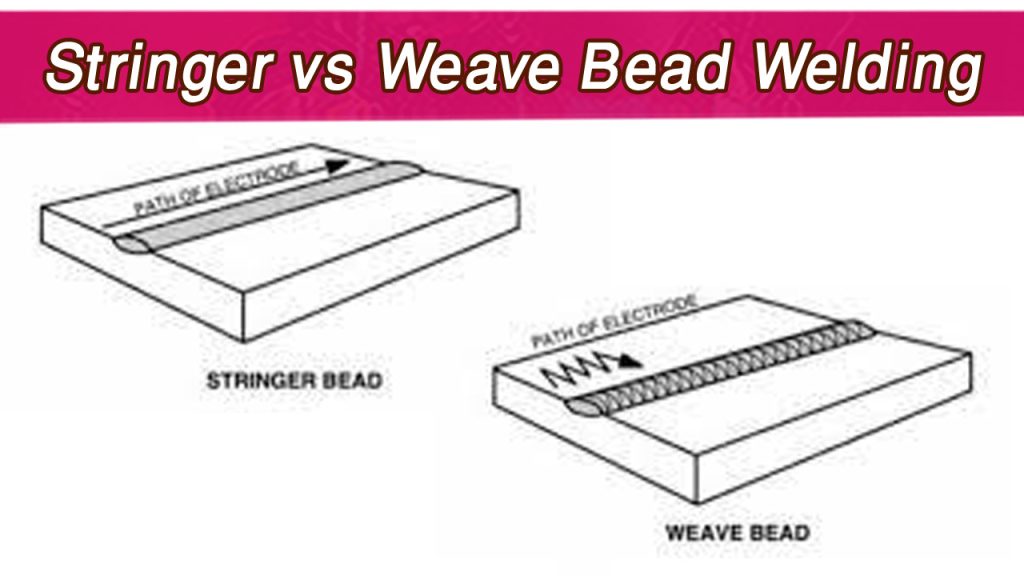

- Gun Angle: Maintain a consistent angle of 10–15 degrees from vertical. Avoid holding the gun too far back or forward.

- Travel Speed: Move the gun steadily and at the right pace. Going too fast or too slow can create an unstable arc.

- Stickout Distance: Keep the wire stickout between ½ to ¾ inch. A shorter or longer stickout can cause irregularities in the weld.

Practicing your technique on scrap metal can help you build muscle memory and consistency.

Choose the Right Polarity

Flux core welding often requires the correct polarity setting on your machine. For most self-shielded flux core wires, DCEN (Direct Current Electrode Negative) is recommended. Using the wrong polarity can increase spatter and lead to weak welds.

Always double-check the wire manufacturer’s specifications to ensure your polarity is set correctly.

Ensure Proper Ventilation

While flux core welding doesn’t require external shielding gas, it still produces gases that can disrupt the weld pool. Ensure your workspace has good ventilation to keep the area clear of excessive fumes and gases. This not only helps with spatter reduction but also improves overall weld quality.

Use Anti-Spatter Spray or Gel

Anti-spatter products can be a lifesaver when you’re dealing with spatter. These sprays or gels create a protective coating on your workpiece and equipment, making it easier to remove spatter after welding.

Here’s how to use them effectively:

- Apply a light coat to the workpiece and nozzle before welding.

- Avoid overspraying, as too much product can interfere with the welding process.

While anti-spatter sprays won’t eliminate spatter entirely, they make cleanup much easier.

Invest in a Better Welding Machine

If you’ve tried everything and still struggle with spatter, your welding machine might be the issue. Older or low-quality machines often lack the precision and stability needed for clean welds.

Upgrading to a modern, high-quality machine with advanced controls can give you more consistency and reduce spatter.

Experience with Reducing Spatter

When I first started flux core welding, spatter felt like an inevitable part of the process. I’d spend hours grinding and cleaning after every project. Over time, I realized that small changes in settings, technique, and preparation could make a massive difference.

One tip that helped me was fine-tuning the wire feed speed. I’d always rush through setup, but once I started testing on scrap metal, I noticed how much smoother my welds became. Cleaning the base metal thoroughly also worked wonders—it’s amazing how a little prep can go a long way.

Now, spatter is no longer a major headache for me. Sure, it’s still there, but with the right steps, it’s manageable and doesn’t slow me down.

Conclusion

Reducing spatter when flux core welding is all about preparation, technique, and using the right equipment. By fine-tuning your machine settings, maintaining proper technique, and ensuring clean surfaces, you can achieve cleaner welds and spend less time on cleanup.

Remember, welding is a skill that improves with practice. Don’t get discouraged if things aren’t perfect right away. Keep experimenting and refining your process, and soon you’ll see a noticeable difference in your results.

Whether you’re a hobbyist or a professional, these tips can help you tackle your projects with confidence and efficiency.

FAQs

Why does flux core welding produce so much spatter?

Spatter is caused by arc instability, poor technique, or contaminated surfaces. Fine-tuning your settings and cleaning your metal can reduce spatter.

Can I eliminate spatter completely in flux core welding?

No, but you can significantly minimize it by using proper technique, high-quality wire, and clean base materials.

What is the best anti-spatter spray for flux core welding?

There are many options available, but look for sprays designed specifically for welding. Brands like CRC and Weld-Aid are popular choices.

How do I clean spatter after welding?

Use a wire brush, grinder, or chipping hammer to remove spatter. Anti-spatter spray can make this process easier.

Does flux core welding always require DCEN polarity?

Most flux core wires require DCEN, but always check the manufacturer’s recommendations for your specific wire.

Endow Russel the owner chief editor of giftendow.com . I am a mechanical engineer and assign to an local firm with much experience in welding and industrial equipment.