Welding is an incredible skill that has shaped industries and innovation for decades. Whether you’re working on a small DIY project or tackling large-scale construction, welding is the backbone of creating strong and durable connections between metals. I’ve explored various welding methods and realized that each type has its unique characteristics and uses.

But how many types of welding are there? And which ones should you know about? In this guide, I’ll walk you through the most common types of welding, their applications, and why they’re essential.

What Is Welding?

At its core, welding is a fabrication process that joins materials, usually metals or thermoplastics, by applying heat, pressure, or both. Unlike other joining methods, welding creates a strong bond, often fusing the materials at a molecular level.

What’s fascinating about welding is its versatility. It can be used in everything from intricate jewelry making to heavy-duty shipbuilding. Let’s dive into the different types of welding and how they’re used.

Common Types of Welding

There are many welding methods, but here are the most common types that every welder should know about:

Shielded Metal Arc Welding (SMAW)

Shielded Metal Arc Welding, often called stick welding, is one of the oldest and most commonly used welding methods. It involves using an electrode (the “stick”) coated in flux to join metals.

How It Works

The electrode creates an arc with the metal surface, generating heat to melt the materials and fuse them. The flux coating burns off to produce a gas shield, protecting the weld from contaminants.

Applications

- Construction and repair work.

- Outdoor projects where portability is key.

- Joining thick metals like steel and iron.

Why I Like It

Stick welding is straightforward and works well in various conditions, including windy or wet environments. It’s a go-to method for many repair jobs.

Gas Metal Arc Welding (GMAW/MIG Welding)

MIG welding is a popular choice for beginners because of its ease of use. This process uses a continuous wire feed and shielding gas to create clean, precise welds.

How It Works

A spool of wire is fed through the welding gun, and an inert gas like argon or carbon dioxide shields the weld from contamination.

Applications

- Automotive repairs.

- Manufacturing and fabrication.

- Projects requiring clean and smooth welds.

Why It’s Great

I often recommend MIG welding to beginners because it’s relatively easy to learn and produces minimal spatter. Plus, it’s versatile enough for thin and thick materials.

Gas Tungsten Arc Welding (GTAW/TIG Welding)

TIG welding is all about precision. It’s a more advanced method that uses a non-consumable tungsten electrode and a shielding gas.

How It Works

The tungsten electrode creates the arc, while a filler material is added manually. Shielding gas, typically argon, protects the weld.

Applications

- Aerospace and automotive industries.

- Welding thin metals like aluminum and stainless steel.

- Projects requiring high-quality, detailed welds.

Why I Love It

TIG welding produces some of the most beautiful and clean welds I’ve ever seen. It’s perfect for projects where aesthetics matter, but it does require more skill and patience.

Flux-Cored Arc Welding (FCAW)

Flux-cored arc welding is similar to MIG welding but uses a special tubular wire filled with flux. This eliminates the need for an external shielding gas.

How It Works

The flux within the wire creates a gas shield when heated, protecting the weld pool from contamination.

Applications

- Outdoor projects in windy conditions.

- Heavy-duty construction and repair work.

- Welding thick materials.

Why It’s Useful

I often use FCAW for outdoor jobs because it’s more forgiving in windy conditions compared to MIG welding. It’s also efficient for large-scale projects.

Oxy-Acetylene Welding (Gas Welding)

Gas welding, especially oxy-acetylene welding, is a classic method that uses a flame to melt and join metals.

How It Works

A mixture of oxygen and acetylene gas produces a high-temperature flame capable of welding or cutting metals.

Applications

- Jewelry making and art projects.

- Automotive repairs.

- Cutting and shaping metals.

Why It’s Versatile

This method doesn’t require electricity, making it highly portable. I’ve used it for everything from cutting steel plates to repairing small metal components.

Plasma Arc Welding (PAW)

Plasma arc welding is a high-precision method that uses a plasma torch to create an extremely focused arc.

How It Works

Plasma gas is ionized to create a high-energy arc capable of welding thin or thick metals with precision.

Applications

- Aerospace and electronics industries.

- Precision welding of thin materials.

Why It Stands Out

The precision of plasma arc welding is unmatched, but it’s more suited for advanced welders due to its complexity.

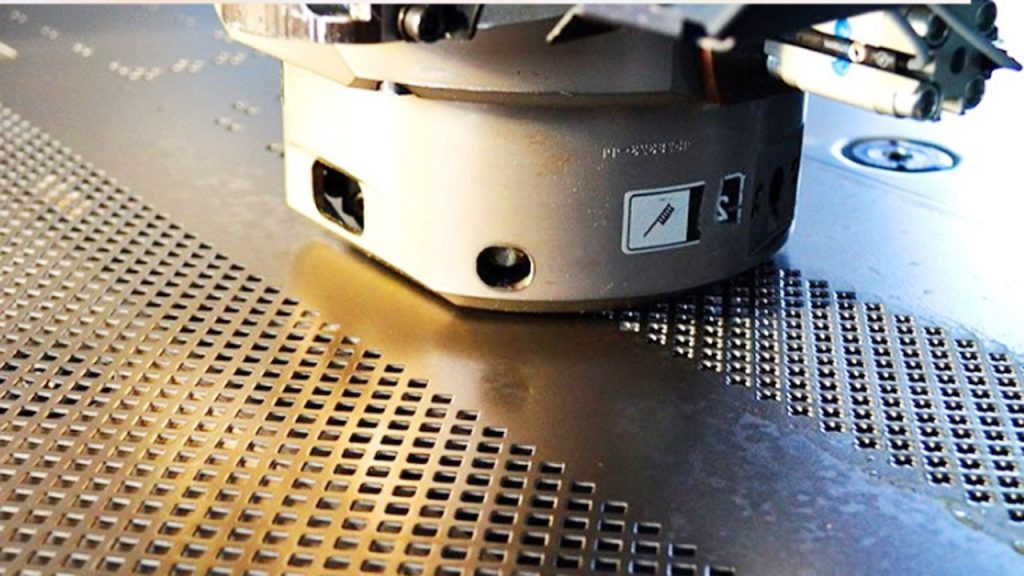

Resistance Welding

Resistance welding uses electrical resistance and pressure to join metals. There are several types within this category, including spot welding and seam welding.

How It Works

Electrical current passes through the metals, generating heat to fuse them.

Applications

- Automotive manufacturing.

- Joining sheet metals.

- Projects requiring fast and efficient welds.

Why It’s Efficient

I’ve seen this method used in mass production settings where speed and efficiency are critical.

Submerged Arc Welding (SAW)

Submerged arc welding involves a continuously fed electrode and a blanket of granular flux to shield the weld.

How It Works

The flux covers the weld area, preventing contamination and producing clean, high-quality welds.

Applications

- Heavy-duty construction.

- Welding pipelines and pressure vessels.

Why It’s Powerful

SAW is ideal for large projects because it produces strong, consistent welds with minimal spatter.

Less Common Types of Welding

While the methods above are the most common, there are a few specialized types worth mentioning:

- Electron Beam Welding: Uses a focused beam of electrons to join materials, often in aerospace applications.

- Friction Welding: Relies on frictional heat to fuse materials, commonly used in automotive manufacturing.

- Laser Welding: Uses a high-intensity laser beam for precision work, such as in electronics.

How to Choose the Right Welding Type

Choosing the right welding method depends on several factors:

- Material Type: Some methods work better on specific metals.

- Project Size: For large-scale projects, methods like SAW or FCAW are ideal.

- Skill Level: Beginners might prefer MIG or stick welding.

- Environment: Outdoor projects may require FCAW due to wind resistance.

Conclusion

Welding is an essential skill with endless applications. Understanding the different types of welding can help you choose the best method for your projects, whether you’re working on a small DIY task or a major industrial job.

Each welding type has its strengths, and the right choice depends on your needs, materials, and skill level. Personally, I’ve found that exploring different methods has not only improved my skills but also opened up new opportunities in welding.

If you’re new to welding, start with simple methods like MIG or stick welding and gradually move to advanced techniques like TIG or plasma welding. Remember, practice makes perfect, and every project is a chance to learn something new.

FAQs

What is the easiest type of welding for beginners?

MIG welding is the easiest for beginners due to its simplicity and clean welds.

Which welding method is the strongest?

TIG welding often produces the strongest and most precise welds, especially for critical applications.

Can all welding methods be used outdoors?

No. Methods like MIG welding require shielding gas, which can be affected by wind. FCAW is better for outdoor projects.

What type of welding is used in automotive work?

MIG and spot welding are commonly used in automotive repairs and manufacturing.

Is gas welding still relevant today?

Yes! Gas welding remains popular for artistic projects, small repairs, and applications where electricity isn’t available.

Endow Russel the owner chief editor of giftendow.com . I am a mechanical engineer and assign to an local firm with much experience in welding and industrial equipment.