If you’ve ever marveled at how large ships, heavy-duty pipelines, or industrial storage tanks are constructed, you might be curious about the process behind those smooth, strong welds. One of the techniques responsible for this impressive craftsmanship is Submerged Arc Welding (SAW).

Image by westermans

When I first explored SAW, I was fascinated by its ability to create flawless welds with incredible efficiency. Unlike other welding processes that expose you to bright sparks and fumes, SAW keeps everything contained under a layer of protective flux, making it a quieter and cleaner method.

I’ll walk you through exactly how this remarkable process works, in simple terms, so you can see why it’s a preferred technique for heavy-duty welding.

What is Submerged Arc Welding?

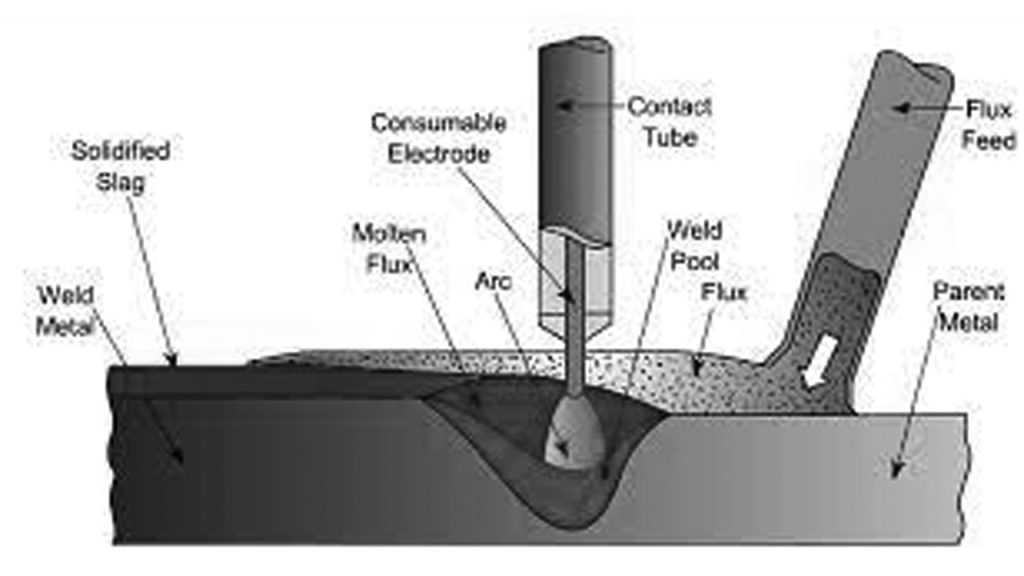

Before diving into the mechanics of SAW, let’s first understand what it is. Submerged Arc Welding is an arc welding process where a consumable electrode is continuously fed to create an electric arc with the base material. The arc, weld pool, and molten metal are submerged under a layer of granular flux.

This flux plays a vital role in the process. It not only shields the weld from atmospheric contamination but also stabilizes the arc and enhances the quality of the weld. The result? A clean, smooth, and durable weld that requires minimal finishing.

Core Components of Submerged Arc Welding

To understand how SAW works, you need to know the key elements involved in the process:

Electrode

The electrode is a consumable wire that’s continuously fed into the welding zone. It melts to form the filler material that joins the base metals together. Electrodes come in various sizes and compositions, depending on the material being welded.

Granular Flux

The granular flux is a powdery substance that covers the welding zone. It performs several functions, including:

- Protecting the molten weld from contaminants like oxygen and nitrogen.

- Stabilizing the arc for consistent performance.

- Forming a slag layer that protects the weld pool as it cools.

Power Supply

SAW relies on a constant power source to maintain the electric arc. Both AC (alternating current) and DC (direct current) power can be used, depending on the specific application and desired results.

Welding Machine

A specialized welding machine or tractor feeds the electrode and flux automatically. In automated setups, this ensures consistent weld quality and efficiency.

Base Material

The base material is the metal you’re welding. SAW is typically used on thick materials like steel and stainless steel.

Submerged Arc Welding Process

Now that you know the components, let’s break down the step-by-step process of how SAW works:

Setup

The first step is setting up the welding equipment. The base material is cleaned to remove any dirt, grease, or rust that could interfere with the weld quality. The welding machine is then calibrated, and the appropriate electrode and flux are selected for the job.

Flux Application

Granular flux is applied to the weld joint, fully covering the area where the weld will take place. The amount of flux used is critical—too little won’t provide adequate protection, while too much can waste material.

Arc Initiation

Once everything is in place, the welding process begins. An electric arc is struck between the electrode and the base material. The intense heat generated by the arc melts both the electrode and the base material, creating a molten weld pool.

Welding Under Flux

As the welding progresses, the molten weld pool remains submerged under the layer of flux. This flux melts partially, forming a slag layer that floats on top of the weld pool. The slag protects the molten metal as it cools and solidifies.

Cooling and Slag Removal

After the weld is complete, the slag layer is removed to reveal the finished weld. Depending on the application, additional finishing steps, like grinding or polishing, may be performed.

Why Use Submerged Arc Welding?

SAW isn’t just another welding technique—it’s a powerhouse for industrial applications. Here are some reasons why it’s preferred:

High Efficiency

With a continuous feed of electrode and automated operation, SAW is incredibly efficient. It allows for higher deposition rates compared to other welding methods, meaning more metal is laid down in less time.

Superior Weld Quality

The protective flux ensures that the weld is free from impurities, resulting in a strong and defect-free joint. The slag layer also helps create a smooth finish, reducing the need for post-weld cleanup.

Clean and Safe Operation

Unlike other methods, SAW doesn’t produce sparks, smoke, or harmful UV radiation. The submerged arc keeps everything contained, making it safer and more comfortable for the operator.

Deep Penetration

SAW can achieve deep weld penetration, making it ideal for joining thick materials in heavy-duty applications.

Where is Submerged Arc Welding Used?

SAW is widely used in industries that demand high-quality, high-strength welds. Here are some common applications:

- Shipbuilding: Joining large steel plates for ship hulls and decks.

- Pipeline Welding: Ensuring leak-proof joints in oil, gas, and water pipelines.

- Structural Construction: Fabricating bridges, buildings, and industrial frameworks.

- Pressure Vessel Manufacturing: Creating tanks and vessels that hold gases or liquids under pressure.

- Automotive and Heavy Equipment: Welding components for trucks, tractors, and construction machinery.

Submerged Arc Welding vs Other Processes

Let’s see how SAW compares to other popular welding techniques:

| Process | Key Strengths | Limitations |

|---|---|---|

| SAW | High efficiency, clean welds | Limited to flat positions |

| MIG Welding | Versatile, fast | Requires shielding gas |

| TIG Welding | Precise, aesthetic welds | Slower and less efficient |

| Stick Welding | Portable, affordable | More cleanup required |

SAW stands out for its ability to handle large-scale, industrial applications, while other methods are better suited for smaller or more delicate tasks.

Challenges of Submerged Arc Welding

While SAW offers many benefits, it’s not without its challenges:

Positional Limitations: SAW is best for flat or horizontal welding and isn’t suitable for vertical or overhead positions.

High Initial Costs: The equipment and setup can be expensive, making it less accessible for small-scale operations.

Material Restrictions: SAW is primarily used for thick steel and stainless steel. It’s not ideal for thin materials or non-ferrous metals like aluminum.

FAQs

Can Submerged Arc Welding be automated?

Yes, SAW is often used with automated systems, making it ideal for repetitive, large-scale projects.

What materials can SAW weld?

SAW is most effective on thick steel and stainless steel. It’s not suitable for thin materials or aluminum.

Is SAW safe to use?

Yes, SAW is safer than open-arc welding methods since the flux layer contains sparks, fumes, and UV radiation.

Can SAW be used outdoors?

SAW is typically used in controlled environments. While it can be used outdoors, wind or moisture can affect the flux and weld quality.

What are the power requirements for SAW?

SAW can use both AC and DC power, depending on the specific application and welding conditions.

Conclusion

Submerged Arc Welding (SAW) is an incredibly efficient and precise welding technique that stands out in industrial applications. From shipbuilding to heavy equipment fabrication, SAW delivers clean, strong, and defect-free welds that can handle extreme conditions.

What makes SAW truly remarkable is its ability to streamline the welding process while maintaining superior quality. In my experience, it’s the go-to method for large-scale projects where speed and strength are critical.

If you’re exploring welding techniques for your next project, SAW is worth considering. With the right equipment and setup, it can transform your welding game and deliver results that speak for themselves.

Endow Russel the owner chief editor of giftendow.com . I am a mechanical engineer and assign to an local firm with much experience in welding and industrial equipment.