Welding galvanized steel can be tricky. The coating makes it tough.

You need the right process to get strong, clean welds. Galvanized steel is popular for its rust resistance. It’s used in construction, automotive, and various industries. But welding it requires special care. The zinc coating can cause issues like weak welds and toxic fumes.

Choosing the best welding process is crucial. This ensures safety, efficiency, and quality. In this guide, we’ll explore the top welding methods for galvanized steel. You’ll learn which processes work best and why. Whether you’re a beginner or experienced welder, this information will help you achieve better results. Read on to find the best welding technique for your project!

Credit: galvanizeit.org

Popular Welding Processes

When welding galvanized steel, choosing the right process is crucial. Different welding methods offer unique benefits. Each has its own set of advantages and limitations. Here, we’ll discuss three popular welding processes for galvanized steel. These include MIG Welding, TIG Welding, and Stick Welding.

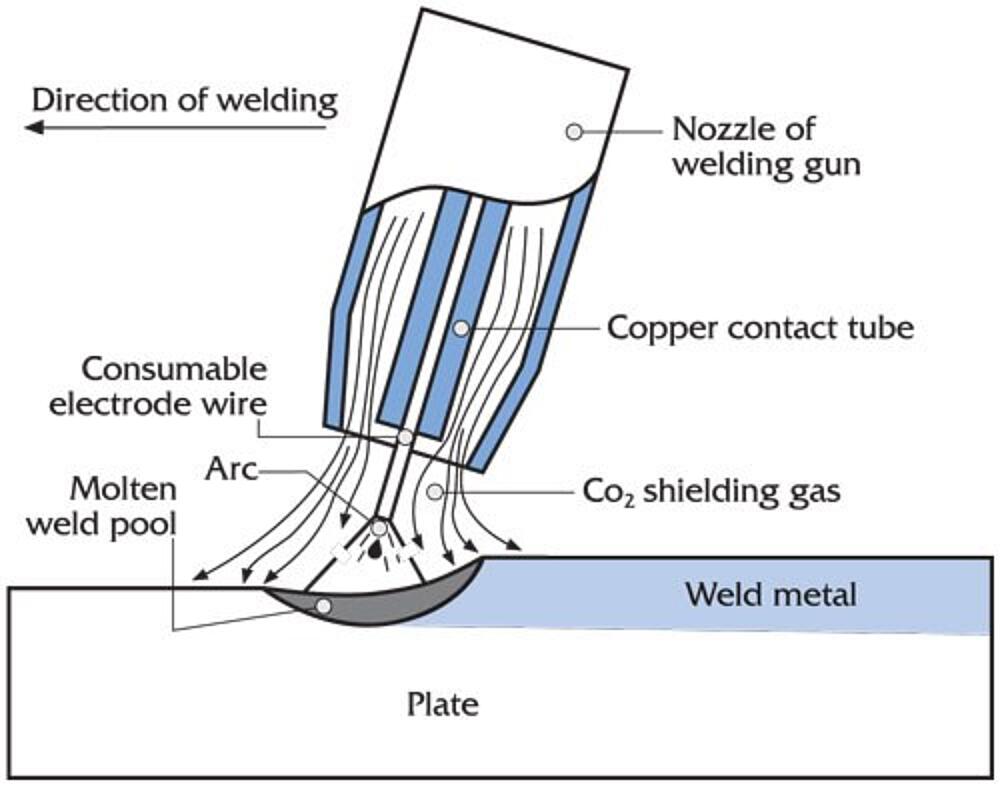

Mig Welding

MIG Welding, or Metal Inert Gas welding, is widely used. It’s known for its speed and ease of use. This process involves feeding a wire continuously to create the weld. It’s ideal for thin to medium-thick galvanized steel. The process produces minimal spatter. This ensures a cleaner and stronger weld.

MIG welding also offers good control over the welding arc. This makes it suitable for beginners. Proper ventilation is essential. Galvanized steel emits harmful fumes during welding. Always wear protective gear to stay safe.

Tig Welding

TIG Welding, or Tungsten Inert Gas welding, offers precision. It uses a non-consumable tungsten electrode. This method is slower but produces high-quality welds. It’s perfect for thin galvanized steel sheets. The process allows for better control over heat input. This reduces the risk of burning through the material.

TIG welding requires more skill and experience. It’s not recommended for beginners. The process also demands good ventilation. Always ensure a clean workspace. This will help achieve the best results.

Stick Welding

Stick Welding, also known as Shielded Metal Arc Welding (SMAW), is versatile. It’s suitable for thick galvanized steel. This method uses a consumable electrode coated in flux. It’s effective for outdoor welding. The process is less sensitive to wind and drafts.

Stick welding produces more spatter. Cleanup is necessary after welding. It’s not the best choice for thin materials. The method requires some skill but is manageable with practice. Ensure proper ventilation and safety measures. Galvanized steel can emit harmful fumes during welding.

Mig Welding Techniques

When it comes to welding galvanized steel, the MIG (Metal Inert Gas) welding technique stands out for its efficiency and ease of use. Whether you are a seasoned welder or just starting, understanding the nuances of MIG welding can help you achieve professional results. Let’s dive into the specifics of this technique, focusing on equipment setup, best practices, and the pros and cons.

Equipment And Setup

Getting the right equipment is the first step towards successful MIG welding. Here’s a quick rundown:

- Welding Machine: Opt for a MIG welder with adjustable settings to control the voltage and wire speed.

- Welding Wire: Use ER70S-6 wire for galvanized steel due to its deoxidizers which help in dealing with the zinc coating.

- Gas: A mixture of Argon and CO2 is ideal. A common ratio is 75% Argon and 25% CO2.

- Safety Gear: Don’t skimp on safety. Use a welding helmet, gloves, and a proper welding jacket.

Once you have your equipment, setting it up correctly is crucial. Make sure to clean the galvanized steel to remove any zinc coating from the area you’ll be welding. This will minimize the risk of zinc fumes, which are harmful when inhaled.

Best Practices

Following best practices can make a world of difference:

- Pre-Clean the Metal: Remove the zinc coating from the welding area using a wire brush or grinder.

- Control Your Heat: Use lower heat settings to prevent burning through the thin zinc coating.

- Maintain a Steady Hand: Keep the welding gun at a consistent angle, ideally around 15 degrees.

- Work in a Well-Ventilated Area: Always weld in areas with good ventilation to avoid inhaling harmful fumes.

Advantages And Disadvantages

Like any welding process, MIG welding has its pros and cons:

| Advantages | Disadvantages |

|---|---|

|

|

MIG welding galvanized steel can be a straightforward process with the right knowledge and preparation. While it has its challenges, the benefits often outweigh the drawbacks, making it a preferred method for many welders. Remember, practice makes perfect, so don’t be afraid to experiment and refine your technique. Happy welding!

Tig Welding Techniques

When it comes to welding galvanized steel, choosing the right technique is crucial. TIG welding, also known as Tungsten Inert Gas welding, is one of the most effective methods. In this section, we’ll explore the essentials of TIG welding techniques, covering everything from equipment and setup to best practices, advantages, and disadvantages.

Equipment And Setup

Getting the right equipment is half the battle. For TIG welding galvanized steel, you will need a TIG welding machine, tungsten electrode, filler rod, and a protective gas like argon.

- TIG Welding Machine: Choose one with adjustable settings for precision.

- Tungsten Electrode: A 2% thoriated tungsten is often recommended.

- Filler Rod: Use a rod compatible with galvanized steel.

- Protective Gas: Argon is the most commonly used gas for TIG welding.

Setting up the machine is straightforward. Connect the gas line, attach the electrode, and set the machine to a low amperage to prevent overheating. Don’t forget to wear proper safety gear, including gloves and a welding helmet.

Best Practices

TIG welding requires a steady hand and a bit of patience. Here are some best practices to keep in mind:

- Clean the Metal: Remove the zinc coating around the welding area to prevent toxic fumes.

- Use Low Amperage: This helps to control heat and avoid burning through the metal.

- Maintain a Short Arc: Keep the arc length short for better control and penetration.

- Work in a Well-Ventilated Area: This is crucial for safety, as galvanized steel can release harmful fumes.

Consistency is key. Practice makes perfect, so don’t get discouraged if your first few attempts aren’t flawless.

Advantages And Disadvantages

Like any welding process, TIG welding comes with its own set of pros and cons.

| Advantages | Disadvantages |

|---|---|

|

|

So, is TIG welding the best choice for galvanized steel? It depends on your needs. If precision and quality are your top priorities, then TIG welding is worth considering.

Credit: www.reddit.com

Stick Welding Techniques

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a popular method for welding galvanized steel. This technique involves using a consumable electrode coated in flux to lay the weld. It’s favored for its simplicity and effectiveness, especially in environments where other methods might struggle. If you’re looking to master stick welding galvanized steel, let’s dive into some essential details.

Equipment And Setup

Setting up your equipment correctly is crucial for effective stick welding. Here’s what you’ll need:

- Welding Machine: Ensure you have a reliable welding machine that can handle the power requirements of stick welding.

- Electrodes: Use electrodes suitable for galvanized steel, typically with a basic coating that helps in reducing zinc fumes.

- Safety Gear: Always wear a welding helmet, gloves, and protective clothing to safeguard against sparks and harmful fumes.

- Ventilation: Ensure your workspace is well-ventilated to avoid inhaling zinc oxide fumes which can be hazardous.

Best Practices

Stick welding galvanized steel requires some specific practices to ensure quality welds:

- Pre-Cleaning: Remove the galvanized coating from the welding area using a grinder or a wire brush to minimize zinc fumes and ensure a cleaner weld.

- Proper Electrode Handling: Store electrodes in a dry place and handle them carefully to prevent damage to the coating.

- Correct Settings: Adjust the amperage settings on your welding machine to match the electrode specifications. This typically ranges between 70-120 amps for most electrodes.

- Steady Hand: Maintain a consistent arc length and travel speed. A steady hand ensures a smooth bead and reduces the risk of defects.

Advantages And Disadvantages

While stick welding is a go-to for many, it’s important to weigh its pros and cons.

| Advantages | Disadvantages |

|---|---|

|

|

In conclusion, stick welding is a reliable and efficient method for working with galvanized steel. With the right equipment and adherence to best practices, you can achieve strong and durable welds. However, always be aware of the disadvantages and take necessary precautions to ensure safety and quality.

Safety Considerations

Welding galvanized steel is no walk in the park. It involves risks that can affect your health and safety. Whether you’re a novice or a seasoned welder, understanding these risks and knowing how to protect yourself is crucial. In this section, we’ll discuss the potential health risks and the protective gear you need to stay safe.

Health Risks Of Welding Galvanized Steel

When you weld galvanized steel, you expose yourself to zinc fumes. Zinc is part of the galvanizing process, which helps protect steel from rust. But when heated, it turns into fumes that are harmful to inhale. These fumes can cause “metal fume fever,” a condition that feels like a bad flu.

- Metal Fume Fever: Symptoms include fever, chills, nausea, and muscle pain.

- Respiratory Issues: Inhaling zinc fumes can lead to coughing, shortness of breath, and chest tightness.

- Skin and Eye Irritation: Direct contact with fumes or sparks can irritate your skin and eyes.

Remember, safety first! You don’t want to trade a quick job for long-term health problems.

Protective Gear And Equipment

Now that you know the risks, let’s talk about how to protect yourself. Wearing the right gear can make a world of difference. Here’s what you need:

| Equipment | Purpose |

|---|---|

| Respirator | Filters out harmful zinc fumes to protect your lungs. |

| Welding Helmet | Protects your eyes and face from sparks and UV rays. |

| Welding Gloves | Shields your hands from heat and sparks. |

| Protective Clothing | Non-flammable clothing prevents burns and skin irritation. |

Additionally, ensure your workspace is well-ventilated. Good ventilation reduces the concentration of fumes in the air, making it safer to breathe. If you can, weld outdoors or use an exhaust system.

Think of it this way: welding without the right gear is like jumping out of a plane without a parachute. You wouldn’t do that, right? The same caution applies here.

Credit: www.youtube.com

Expert Tips

Welding galvanized steel requires certain techniques and precautions to ensure strong, clean welds. Many welders face challenges due to the zinc coating. This coating can produce harmful fumes and affect the weld quality. Below are some expert tips to help you achieve the best results.

Common Mistakes To Avoid

One common mistake is not cleaning the zinc coating. The zinc can contaminate the weld. This can lead to weak joints. Always remove the coating before welding.

Another mistake is using the wrong welding process. For galvanized steel, use MIG or TIG welding. These processes work best with this type of metal.

Also, avoid welding too fast. Fast welding can cause poor penetration. This leads to weak welds. Take your time for strong, durable joints.

Enhancing Weld Quality

To enhance weld quality, use a high-quality filler material. This ensures a strong bond. It also helps in reducing porosity in the weld.

Maintain a clean work area. Dirt and debris can affect weld quality. Clean your workspace before starting.

Use proper ventilation. Welding galvanized steel produces fumes. Good ventilation helps in protecting your health. It also keeps the work area safe.

Adjust your welding parameters. Use the right settings for heat and speed. This ensures a smooth and strong weld. Practice on scrap pieces first to get the settings right.

Frequently Asked Questions

What Is The Best Way To Weld Galvanized Steel?

The best way to weld galvanized steel is to remove the zinc coating from the welding area first. Use a wire brush or grinder. Weld with proper ventilation to avoid harmful fumes. Apply a cold galvanizing spray to the welded area to restore corrosion protection.

Why Do You Drink Milk After Welding Galvanized?

Drinking milk after welding galvanized steel is believed to help counteract zinc poisoning. Milk contains calcium, which may bind to zinc and reduce its absorption.

What Is The Best Welding Rod For Welding Galvanized Steel?

The best welding rod for galvanized steel is the E6011. It handles the zinc coating well and provides good penetration. Use proper ventilation to avoid toxic fumes.

Will A Mig Welder Weld Galvanised Steel?

Yes, a MIG welder can weld galvanized steel. Remove the zinc coating first. Use proper ventilation and safety gear.

Conclusion

Choosing the best welding process for galvanized steel ensures safety and quality. MIG welding is great for beginners. TIG welding offers precision. Stick welding works well outdoors. Always clean the steel first. Proper ventilation is crucial. Safety gear protects from harmful fumes.

Each method has unique benefits. Select based on your needs and skill level. Practice improves results. Happy welding!