Calculating welding strength is crucial for ensuring safety and durability. It helps in assessing if a weld can hold up under pressure.

Welding joins two pieces of metal to create a strong bond. But how can you be sure the weld will hold? Knowing how to calculate welding strength can save you from potential failures. It involves understanding the weld’s size, material, and the forces it will face.

By learning the correct method, you can make accurate predictions about a weld’s performance. This guide will walk you through the steps to calculate welding strength, making it easier to ensure your projects are both safe and sturdy. Whether you’re a beginner or experienced welder, mastering this skill is essential.

Introduction To Welding Strength

Have you ever wondered how bridges, skyscrapers, and even your car stay intact? The secret lies in something called welding strength. It’s the backbone of many structures, ensuring they are safe and sound. But what exactly is welding strength, and why is it so crucial? Let’s dive in and find out!

Importance Of Welding Strength

Imagine building a bridge without knowing if the welds can hold the weight of vehicles. Scary, right? That’s why understanding welding strength is vital. It helps engineers and builders ensure that structures can withstand stress and pressure. Here are a few reasons why welding strength matters:

- Safety: Proper welding strength ensures that structures won’t collapse, protecting lives.

- Durability: Strong welds last longer, reducing the need for repairs.

- Cost-Effectiveness: It saves money in the long run by preventing failures and accidents.

Applications In Various Industries

Welding strength isn’t just a fancy term used by engineers. It plays a crucial role in many industries. Let’s take a look at some of the places where welding strength is a real game-changer:

- Construction: From skyscrapers to residential buildings, strong welds ensure that structures stand tall and firm.

- Automotive: Ever wondered how your car stays in one piece? Welding strength ensures that each part is securely joined.

- Aerospace: In the world of aviation, welding strength is critical for the safety of aircraft.

- Manufacturing: Machines and tools used in factories depend on strong welds to function correctly.

Understanding and calculating welding strength is like having a superpower in the engineering world. It ensures everything, from the tallest buildings to the smallest gadgets, is safe and reliable. So next time you cross a bridge or fly in a plane, you’ll know a little more about what keeps it all together. Pretty cool, right?

Factors Affecting Welding Strength

When it comes to welding, strength is crucial. But have you ever wondered what really affects the strength of your weld? Understanding these factors can make a world of difference in your projects. Let’s dive into some key elements that impact welding strength.

Material Properties

The first factor to consider is the material you’re working with. Different materials have distinct properties that can affect weld strength. Some materials are more malleable, while others are more brittle. Here’s a simple breakdown:

- Steel: Strong and durable, but needs proper treatment.

- Aluminum: Lightweight and corrosion-resistant, but requires careful handling.

- Titanium: Extremely strong and lightweight, but can be costly.

As an example, I once worked on a project using aluminum. I noticed that the welds were more prone to cracking until I adjusted my technique. It was a valuable lesson in understanding material properties.

Type Of Welding Process

Next up, the type of welding process you choose plays a significant role. Different methods can produce varying strengths. Here are a few common welding processes:

- MIG Welding: Ideal for thin to medium thickness materials. It’s fast but requires clean surfaces.

- TIG Welding: Great for precision work and a clean finish. It’s slower but offers strong welds.

- Stick Welding: Versatile and works well outdoors. It’s robust but can be messy.

Choosing the right process can make a huge difference. Think of it like choosing the right tool for the job. Would you use a hammer for a screw? Probably not. The same goes for welding processes.

In conclusion, understanding material properties and choosing the right welding process are key to achieving strong welds. So, next time you’re welding, remember these factors. Your projects will thank you!

Types Of Welds

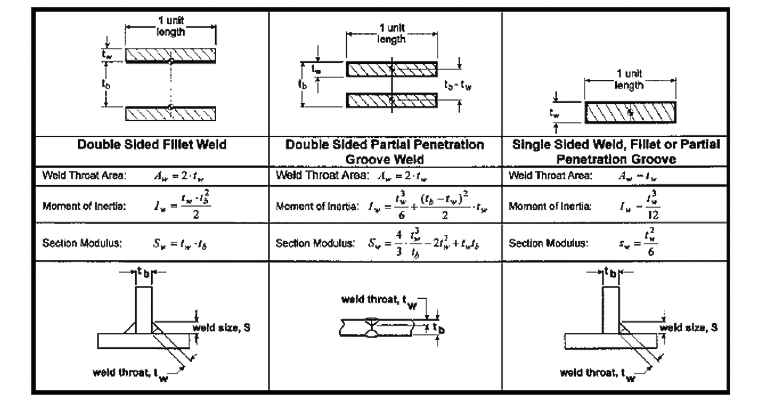

Understanding the types of welds is crucial for calculating welding strength. Different welds offer different strength characteristics. This knowledge helps in choosing the right type for your project. Let’s explore two common types: Butt Welds and Fillet Welds.

Butt Welds

Butt welds join two pieces of metal end-to-end. They create a strong and seamless joint. This type of weld is common in pipelines and structural steel. The welding process involves aligning the edges of the two metal pieces. Then, a weld bead is applied along the joint. Butt welds can be single or double-sided.

Single-sided butt welds are accessible from one side only. Double-sided welds can be accessed from both sides. Double-sided welds often provide greater strength. This weld type is ideal for metals of the same thickness. Proper alignment is key to achieving strong butt welds.

Fillet Welds

Fillet welds join two pieces at a right angle. These welds are triangular in shape. They are common in T-joints, lap joints, and corner joints. Fillet welds are versatile and easy to apply. They can be done on metals of different thicknesses.

To create a fillet weld, the welder applies the weld bead along the joint’s intersection. The size of the fillet weld affects its strength. Larger welds generally provide more strength. However, balance is essential. Too large a weld can introduce stress points.

Fillet welds are useful in many applications. They offer flexibility and reliability. Proper technique ensures strong and durable welds.

Credit: risa.com

Methods For Calculating Welding Strength

Calculating welding strength is essential for ensuring the durability of welded joints. Various methods exist to determine the strength of a weld. Each method offers unique insights and accuracy levels. By understanding these methods, you can select the best approach for your needs.

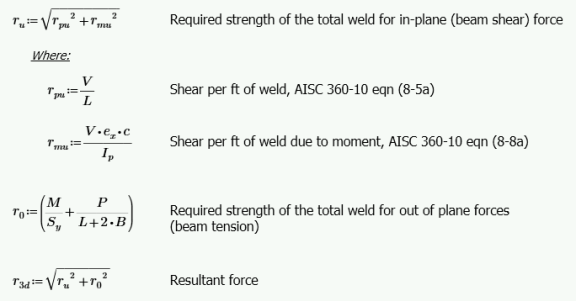

Analytical Methods

Analytical methods use mathematical equations to calculate welding strength. These methods consider factors like material properties and weld dimensions. Engineers often rely on these methods for precise calculations.

One common analytical method is the use of stress analysis. This method involves determining the stresses acting on the weld. By calculating these stresses, engineers can predict the weld’s strength. Another popular method is the use of finite element analysis (FEA). FEA simulates the welding process and predicts the resulting strength.

Empirical Formulas

Empirical formulas provide a simpler way to estimate welding strength. These formulas are based on experimental data and observations. They offer a quick and easy way to calculate weld strength.

One widely used empirical formula is the throat thickness method. This formula estimates the weld strength based on the throat thickness of the weld. Another common formula is the weld size method. This method calculates strength based on the size and length of the weld.

Empirical formulas are useful for quick estimates. They are less accurate than analytical methods but still valuable. Use them for preliminary assessments or when detailed analysis is not required.

Tools And Equipment

Calculating welding strength needs the right tools and equipment. These tools ensure accurate measurements and reliable results. Let’s look at the different tools and equipment you might need.

Software For Calculations

Many software programs help with welding strength calculations. These programs simplify complex formulas and equations. They provide precise results quickly and efficiently. Examples include CAD software and welding calculators. They offer features to input material properties and welding parameters. The software then calculates the expected welding strength.

Manual Tools

Manual tools are also essential for calculating welding strength. These include calipers, micrometers, and tensile testing machines. Calipers and micrometers measure the thickness of welded joints. Tensile testing machines test the strength by applying force until the weld breaks. The results help determine the weld’s capacity to withstand stress.

Expert Tips For Accurate Calculations

Calculating welding strength accurately is crucial for strong and safe structures. Expert tips can help you get precise results. This section covers common mistakes and best practices.

Common Mistakes To Avoid

Many people forget to consider the type of materials used. Different materials have different strengths. Ignoring these differences can lead to weak welds. Another mistake is using incorrect measurements. Always double-check your measurements. Using outdated equipment is also a common error. Old tools can give wrong readings. Lastly, skipping the test weld is risky. Always perform a test weld to check your calculations.

Best Practices

Use the right tools for accurate measurements. Modern tools are more reliable. Always consider the material type in your calculations. Different materials need different welding techniques. Follow standard procedures for each type of weld. These procedures are designed for safety and strength. Keep your equipment in good condition. Regular maintenance ensures accurate readings. Practice makes perfect. The more you weld, the better your calculations will be.

Testing And Verification

When it comes to welding, ensuring the strength of your welds is paramount. After all, a weld that can’t hold up under stress is as useful as a chocolate teapot! So, how do we make sure our welds are up to scratch? That’s where testing and verification come into play. This step is crucial to confirm that your welds are as strong as they should be. Let’s dive into the two primary methods of testing: Non-Destructive Testing and Destructive Testing.

Non-destructive Testing

Non-Destructive Testing (NDT) is like a health check-up for your welds without causing any harm. Imagine getting an X-ray or MRI – it’s the same idea. You get to see what’s inside without breaking anything.

Here are some common NDT methods:

- Visual Inspection: This is the simplest form. Just look at the weld. Any cracks or holes? If yes, that’s a problem!

- Ultrasonic Testing: Think of this as an ultrasound for welds. High-frequency sound waves are sent through the weld. The waves bounce back, revealing internal flaws.

- Radiographic Testing: Similar to an X-ray, this method uses radiation to see inside the weld. It’s great for spotting hidden defects.

- Magnetic Particle Testing: This uses magnetic fields to find surface and near-surface flaws. If the weld has cracks, the magnetic particles will gather there, making them easy to spot.

These methods are fantastic because they keep the weld intact while ensuring it’s up to the mark. Now, let’s move to the next method.

Destructive Testing

Destructive Testing (DT) is like a crash test for cars. It involves testing the weld until it breaks. This might sound a bit extreme, but it gives a very clear picture of the weld’s strength.

Here are some common DT methods:

- Tensile Testing: The weld is pulled apart until it breaks. This measures how much force the weld can handle.

- Bend Testing: The weld is bent to check its ductility and strength. If it cracks, it’s not strong enough.

- Impact Testing: This method tests how well the weld can absorb energy. A heavy object is dropped on the weld to see if it can withstand sudden force.

- Macro Etch Testing: This involves cutting the weld and examining it under a microscope. It helps to study the internal structure of the weld.

While DT methods destroy the weld, they provide invaluable insights into its strength and durability. Plus, they ensure that the final product is safe and reliable.

In conclusion, both Non-Destructive and Destructive Testing methods are vital for verifying weld strength. They help ensure that your welds are not only strong but also reliable and safe. So, next time you’re welding, remember the importance of testing and verification – it’s the backbone of quality welding.

Credit: www.youtube.com

Real-world Applications

Understanding how to calculate welding strength is more than just crunching numbers. It’s about ensuring the safety, durability, and efficiency of the structures we rely on every day. Whether you’re working on a skyscraper, a bridge, or a simple metal fence, knowing the real-world applications of welding strength is crucial. Let’s dive into some real-life examples to see how this knowledge is applied in different industries.

Case Studies

Let’s consider a few case studies where calculating welding strength has played a pivotal role:

- Construction Industry: Imagine you’re part of a team building a high-rise building. The beams and columns must withstand enormous stress. Calculating the welding strength ensures these joints don’t fail under load. A minor miscalculation could lead to catastrophic results.

- Automotive Manufacturing: In car production, welding strength affects the vehicle’s safety. Take the example of a car manufacturer who discovered that certain welds in their cars were not strong enough. This led to a recall and significant financial loss. Accurate welding strength calculations could have prevented this.

- Aerospace Engineering: For airplanes, every component must meet strict standards. In one case, a slight error in welding strength calculation caused a joint to fail during a test flight, grounding the fleet until the issue was resolved. This highlights the importance of precise calculations.

Industry Standards

Different industries have specific standards to ensure welded joints are strong and reliable. Here are some key standards you should be familiar with:

- American Welding Society (AWS): AWS provides guidelines and standards for welding practices. Their codes ensure that welds meet safety and quality requirements.

- International Organization for Standardization (ISO): ISO standards cover various aspects of welding, including material compatibility and welding techniques.

- British Standards Institution (BSI): BSI standards ensure that welded structures in the UK meet safety and performance criteria.

Each of these standards provides a framework for calculating welding strength. They help ensure that the welds are robust enough to handle the stresses they will encounter in real-world applications.

In summary, understanding the real-world applications of welding strength is essential for any project involving welded joints. By looking at case studies and adhering to industry standards, you can ensure the safety and reliability of your work.

Credit: blog.red-d-arc.com

Frequently Asked Questions

How Do You Calculate The Strength Of A Weld?

Calculate weld strength by using the formula: Strength = (weld area) x (material strength). Consider factors like weld type, size, and load.

What Is The Formula For Welding Calculation?

The formula for welding calculation is: Heat input (J/mm) = (Voltage x Current x 60) / (Travel Speed x 1000) Ensure units match for accurate results.

How To Check The Welding Strength?

To check welding strength, inspect the weld visually for defects. Perform non-destructive tests like ultrasonic or radiographic testing. Conduct destructive tests such as tensile or bend tests to evaluate strength.

What Is The Rule Of Thumb For Weld Strength?

The rule of thumb for weld strength is that the weld should be as strong as the base material. Ensure proper welding techniques to achieve this.

Conclusion

Calculating welding strength is crucial for safety and durability. Simple formulas help determine the strength. Always consider the materials and welding methods used. Practice ensures accuracy and confidence. Keep refining your skills through real-world applications. This knowledge enhances your welding projects, making them reliable and strong.

Remember, precision and consistency matter in welding. Happy welding!