Welding is an essential skill in many industries. It requires precision and practice.

Are you looking to improve your welding skills or just starting out? This blog post will provide you with the best tips for welding. Whether you’re a beginner or an experienced welder, these tips will help you achieve better results.

Welding can be challenging, but with the right techniques and practices, it becomes more manageable. Understanding the basics and following expert advice can make a significant difference in your work quality. From safety measures to choosing the right equipment, this guide covers it all. Ready to enhance your welding skills? Let’s dive in and explore the best tips for welding success.

Credit: meritusgas.com

Choosing The Right Equipment

Welding can be a rewarding skill. The right equipment is crucial. It ensures safety and quality. Selecting the right tools can make a big difference. This section will guide you through the basics.

Types Of Welding Machines

Welding machines come in various types. Each serves a different purpose. The most common ones include MIG, TIG, and Stick welders. MIG welders are popular. They are easy to use and versatile. TIG welders offer precision. They are great for detailed work. Stick welders are robust. They work well in outdoor conditions.

Essential Welding Tools

Besides the welding machine, other tools are vital. A welding helmet protects your eyes. Gloves shield your hands from heat and sparks. A wire brush is useful. It cleans the metal before welding. Clamps hold your workpieces in place. They ensure stability. Having a chipping hammer helps. It removes slag from the welds. A welding cart keeps your tools organized. It also makes them easy to move around.

Credit: www.westermans.com

Safety Precautions

Welding is a skilled trade that requires attention to detail and safety. Following safety precautions ensures a safe work environment. This section will cover essential safety tips. It includes wearing protective gear and setting up a safe workspace.

Protective Gear

Wearing the right protective gear is crucial. Always wear a welding helmet. It protects your eyes from bright light. Use safety glasses under the helmet for extra protection. Wear gloves to protect your hands from heat and sparks. Use a long-sleeve shirt to cover your arms. Ensure the shirt is flame-resistant. Wear sturdy shoes to protect your feet from falling objects.

Safe Workspace Setup

A safe workspace is important for welding. Clear the area of any flammable materials. Ensure proper ventilation to avoid inhaling fumes. Use welding curtains to protect others from bright light. Keep a fire extinguisher nearby. Check your equipment regularly for any damage. Ensure all cables and wires are in good condition. Keep the workspace clean and organized. A clutter-free area reduces the risk of accidents.

Material Preparation

Material preparation is a crucial step in welding. It ensures strong, clean welds. Without proper preparation, weld quality suffers. Your project may face structural issues. This section covers key steps in material preparation.

Cleaning The Metal

Start by cleaning the metal. Dirt, oil, and rust can weaken welds. Use a wire brush to remove surface contaminants. For stubborn grime, consider using a degreaser. Ensure the metal is dry before welding. Clean metal creates better, stronger welds.

Proper Clamping Techniques

Proper clamping is vital. It keeps materials stable during welding. Use C-clamps or locking pliers for small parts. For larger pieces, bar clamps work well. Ensure clamps are tight but not overdone. Over-tightening can deform the metal. Proper clamping prevents movement and ensures accurate welds.

Mastering Welding Techniques

Welding is an essential skill in many industries. To achieve perfect welds, mastering techniques is crucial. You need precision, practice, and patience. Understanding the right methods can significantly improve your welding results.

Correct Electrode Angles

Using the correct electrode angle is vital. It ensures strong and clean welds. For most welds, a 15 to 20-degree angle works best. This angle helps in better penetration and a smoother finish. Always check the angle before starting. Adjust as needed to avoid defects.

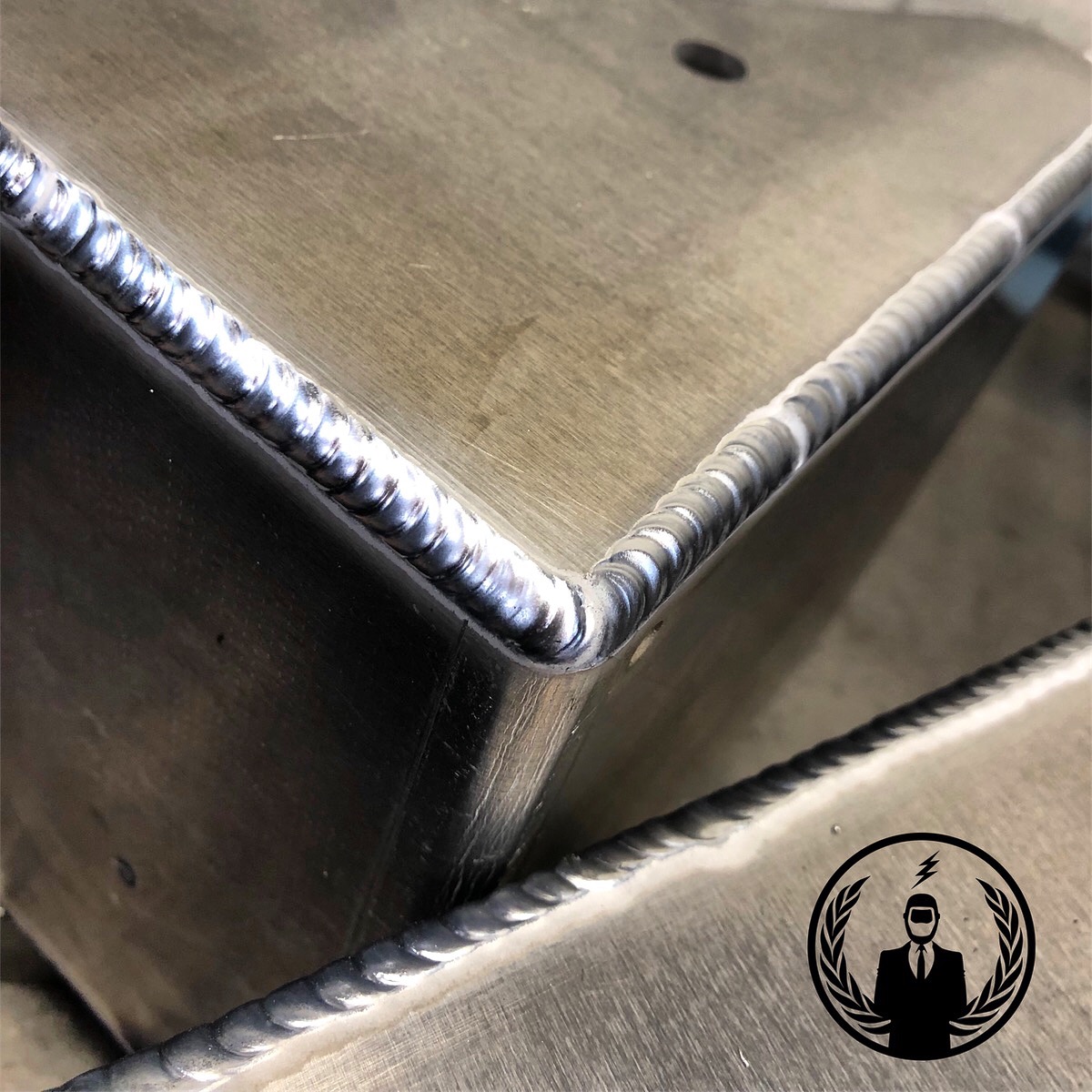

Maintaining Steady Speed

Maintaining a steady speed is key. It ensures consistent weld quality. Moving too fast can cause weak welds. Going too slow may lead to excessive heat and distortion. Practice to find the right pace. Consistency in speed leads to uniform weld beads.

Dealing With Common Issues

Welding can be challenging. Even experienced welders face common issues. Addressing these problems is key to creating strong, clean welds. This section covers tips on preventing warping and avoiding porosity. Both are common issues that can affect weld quality.

Preventing Warping

Warping happens when metal heats up unevenly. This causes the metal to bend or twist. To prevent warping, keep the heat balanced. Use clamps to hold the metal in place. This helps maintain its shape during welding.

Another tip is to weld in small sections. Allow the metal to cool before continuing. This reduces the risk of warping. Also, use a back-step welding technique. Start welding a few inches, then move back and weld the next section. This helps distribute heat more evenly.

Avoiding Porosity

Porosity occurs when gas gets trapped in the weld. It creates holes or bubbles. This weakens the weld. To avoid porosity, clean the metal surface before welding. Remove any rust, oil, or dirt. These contaminants can cause gas pockets.

Use the right shielding gas. Different metals require different gases. Ensure the gas flow rate is correct. Too much or too little gas can cause porosity. Also, check for any leaks in the gas supply. Leaks can introduce air, causing porosity.

Keep a steady welding speed. Moving too fast or slow can trap gas. Practice to find the right pace. This helps create a smooth, strong weld.

Credit: americantorchtip.com

Post-weld Inspection

Post-weld inspection is crucial to ensure the quality and durability of welds. It helps identify any defects that could compromise the structure. This process involves several steps, including checking for cracks and ensuring structural integrity. Let’s dive into these steps in detail.

Checking For Cracks

Cracks can weaken the weld and cause failures. Look closely at the welded area. Use a magnifying glass if needed. Check for any visible cracks. Surface cracks are easier to spot. Internal cracks need special tools to detect. Ultrasonic testing is a common method. It sends sound waves through the weld. Any disruption in the waves indicates a crack. Cracks must be repaired immediately to maintain safety.

Ensuring Structural Integrity

Structural integrity ensures the weld can handle stress. Inspect the weld for uniformity. A uniform weld distributes stress evenly. Uneven welds can create weak points. Check the alignment of the welded parts. Misalignment can cause structural issues. Use visual inspection and measuring tools. Ensure the weld depth is adequate. Shallow welds may not hold up under stress. Conduct load tests if necessary. They help verify the weld’s strength. Regular inspections prevent future problems.

Advanced Tips For Experienced Welders

Welding is an art and science that requires skill, precision, and continuous learning. As an experienced welder, you might feel you’ve mastered the basics, but there’s always room for improvement. Let’s dive into some advanced tips that can refine your technique and take your welding to the next level.

Pulse Welding Methods

Pulse welding is a technique that alternates between high and low current. This method helps control heat input and minimizes distortion, making it ideal for thin materials.

- Consistency: Maintain a steady hand to ensure even pulses. Inconsistent pulses can lead to weak welds.

- Settings: Adjust your machine settings based on the material thickness and type. Proper settings can prevent burn-through and other issues.

Have you ever tried pulse welding? It’s like a rhythmic dance, where timing and precision make all the difference. Imagine welding a car panel without distorting it – that’s the magic of pulse welding.

Using Advanced Welding Modes

Modern welding machines come with advanced modes that can enhance your welding efficiency and quality. Let’s explore a couple of these modes:

- Synergic Mode: This mode automatically adjusts welding parameters based on the material and wire speed. It’s like having an assistant who knows exactly what you need.

- Hot Start and Arc Force: These settings help with arc stability and penetration. Hot Start reduces the chance of the electrode sticking, while Arc Force maintains a steady arc.

Think of these modes as power-ups in a video game. They give you an edge, making your job easier and the results more impressive. Ever had a perfect weld on the first try? These advanced modes can help you get there.

Remember, welding is a journey. Even the most skilled welders can benefit from new techniques and tools. Keep experimenting, stay curious, and never stop learning.

Maintenance Of Equipment

Welding is a skill that demands precision and safety. To ensure your welding projects are successful and safe, maintaining your equipment is crucial. Think of your welding tools as the backbone of your craft. Without regular maintenance, even the best welder can face unnecessary hiccups. Let’s delve into some essential tips to keep your equipment in top-notch condition.

Regular Cleaning

Imagine trying to cook with dirty utensils – not a pleasant thought, right? The same goes for welding equipment. Regular cleaning prevents build-up that can damage your tools and compromise your work.

- Electrode Holders: Make sure to clean electrode holders frequently. Dust and debris can cause poor connections.

- Wire Feeders: Keep wire feeders free of dust and dirt. This ensures smooth wire feeding.

- Welding Torches: Clean the nozzle and other parts of the torch to avoid blockages.

By keeping your equipment clean, you ensure a longer lifespan and better performance.

Routine Checks And Repairs

Ever heard the saying, “A stitch in time saves nine”? It’s especially true for welding equipment. Routine checks can catch small issues before they become big problems.

- Inspect Cables: Look for any signs of wear or damage on cables and replace them if needed.

- Check Connections: Ensure all connections are tight and secure. Loose connections can lead to poor performance or even accidents.

- Test Components: Regularly test components like regulators and gauges to ensure they are working correctly.

Remember, a little time spent on maintenance can save you a lot of hassle down the road.

For example, I once ignored a small fray in a cable, thinking it wasn’t a big deal. A few weeks later, I ended up with a malfunctioning welder right in the middle of an important project. Lesson learned!

In short, keeping your welding equipment clean and regularly checked will not only extend its life but also enhance your welding experience. So, next time you finish a project, take a few minutes to give your tools the care they deserve. Your future self will thank you!

Frequently Asked Questions

How To Be Better At Welding?

Practice regularly and use high-quality equipment. Take welding classes or watch tutorials. Wear proper safety gear. Follow guidelines and experiment with different techniques.

What Is The Number 1 Rule In Welding?

The number 1 rule in welding is safety first. Always wear appropriate protective gear to prevent injuries and hazards.

What Is The Golden Rule In Welding?

The golden rule in welding is safety first. Always wear protective gear, ensure proper ventilation, and inspect equipment before use.

How To Do Perfect Welding?

To achieve perfect welding, clean the metal surfaces thoroughly. Use the right welding technique and maintain proper heat levels. Always wear appropriate safety gear. Practice consistent and steady hand movements. Inspect welds for quality and make adjustments as needed.

Conclusion

Welding can be rewarding with the right tips. Practice these tips regularly. Always prioritize safety. Use the correct tools for the job. Clean your materials before welding. Take breaks to avoid fatigue. Keep learning from experienced welders. Stay updated with new techniques.

Your skills will improve over time. Enjoy the process and keep welding safely.