Welding cables and battery cables serve different purposes. Both are vital in their own ways.

But what sets them apart? Understanding the difference between welding cable and battery cable is crucial. These cables are not interchangeable. Each has unique characteristics and uses that make them suitable for specific tasks. Welding cables are flexible, designed to handle high currents in welding applications.

Battery cables, on the other hand, are used to connect batteries to electrical systems and are less flexible. Knowing these distinctions helps in choosing the right cable for your needs, ensuring safety and efficiency. Let’s dive deeper into the specific differences and why they matter.

Welding Cable Basics

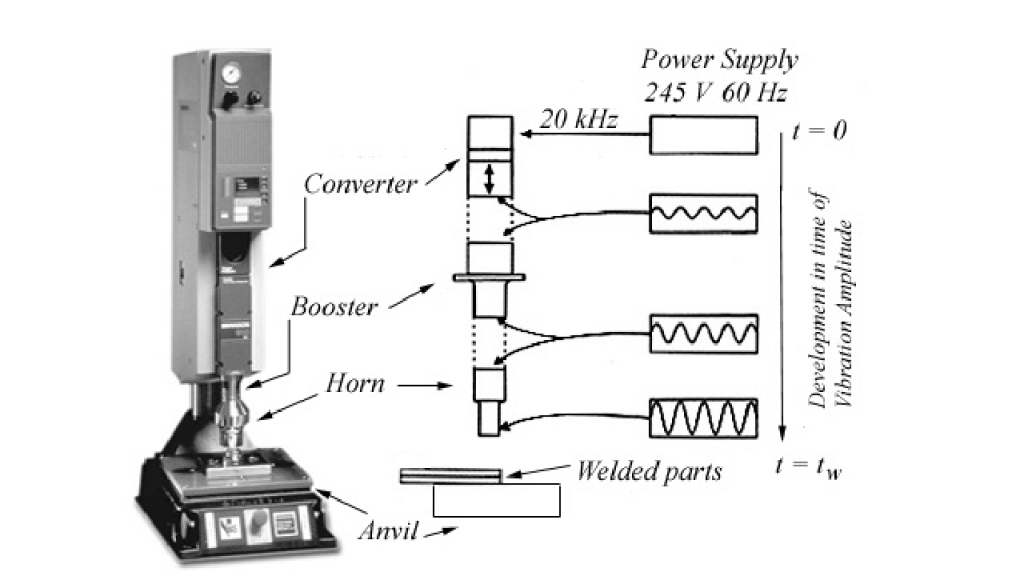

Welding cables are essential in many industries. They connect welding machines to the electrode holder, ground clamp, or arc-welding electrode. Their design ensures flexibility, durability, and high conductivity. These cables handle high currents needed in welding operations. Let’s explore their composition and typical applications.

Material Composition

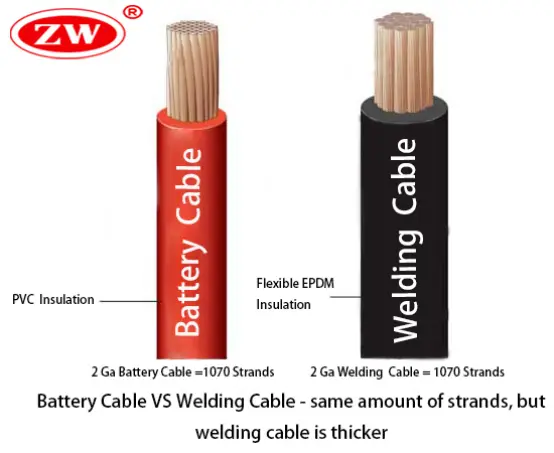

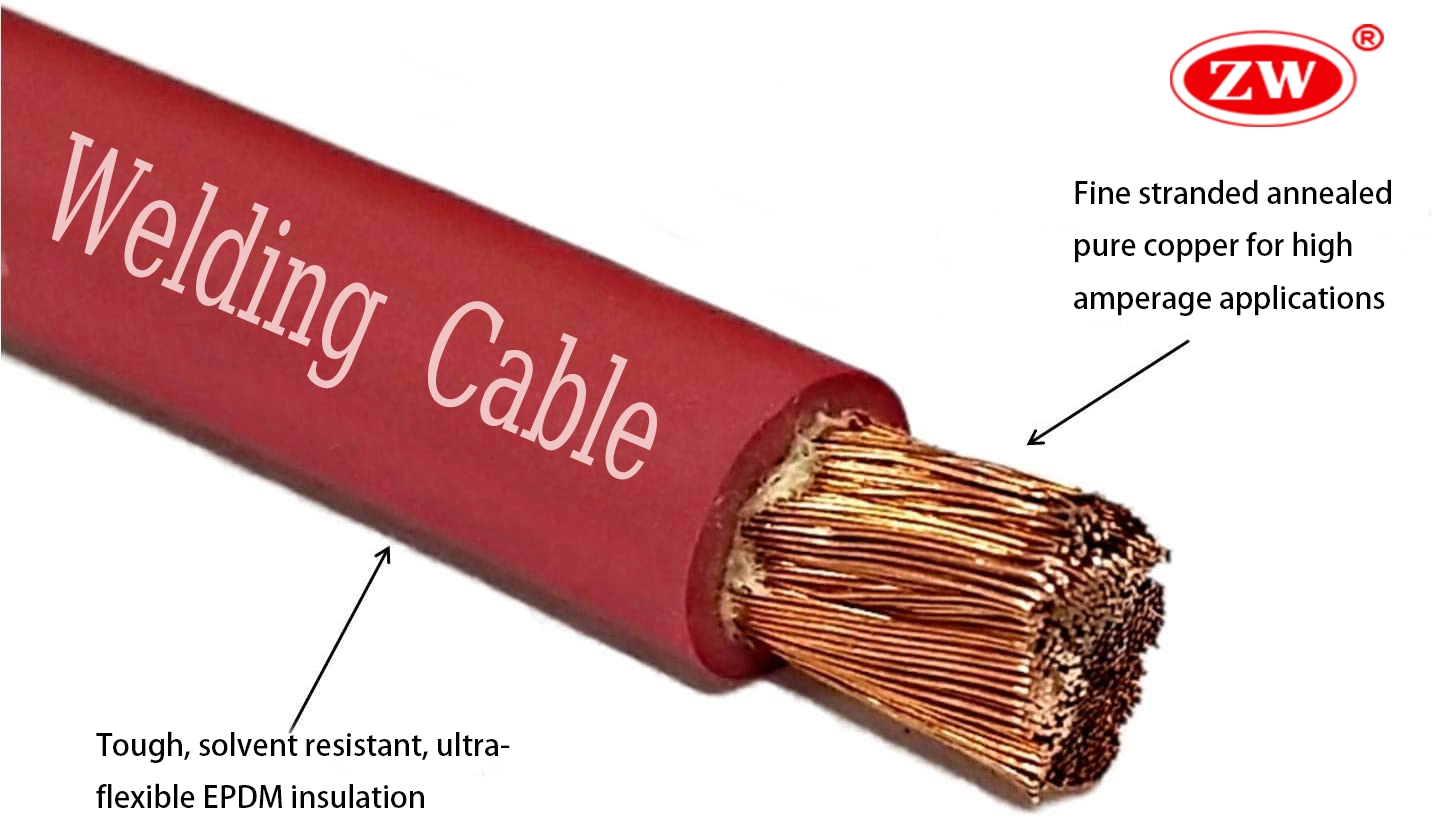

Welding cables are made from fine copper strands. These strands are bundled together for flexibility. The outer jacket is usually rubber or EPDM. This material resists cuts, tears, and abrasion. It also withstands extreme temperatures and harsh environments. This construction ensures the cable lasts long and performs well.

Typical Applications

Welding cables are used in many settings. They are common in construction sites and shipyards. Factories and manufacturing plants also use them. Anywhere welding is performed, these cables are essential. They power the tools needed for joining metal parts. Their flexibility makes them easy to maneuver in tight spaces.

Credit: www.centralwires.com

Battery Cable Basics

When it comes to powering your vehicle, understanding the basics of battery cables is key. Battery cables are essential for transmitting power from the battery to the starter and other electrical components. They are the lifeline of your car’s electrical system, ensuring everything runs smoothly. Let’s dive into the specifics of battery cables, focusing on their material composition and typical applications.

Material Composition

Battery cables are typically made from copper. Why copper, you ask? Because copper is an excellent conductor of electricity. This means it can carry power efficiently from the battery to the starter and other parts of your vehicle. Some battery cables also have a coating of tin to prevent corrosion. Nobody likes a rusty cable! The insulation around the cable is usually made from PVC (polyvinyl chloride), which protects the wire from damage and reduces the risk of electrical shorts.

Typical Applications

Battery cables are used in a variety of applications. Here are some common uses:

- Automobiles: They connect the battery to the starter, ensuring your car starts when you turn the key.

- Boats: Just like in cars, battery cables in boats connect the battery to the engine’s starter.

- Solar power systems: In off-grid solar systems, battery cables connect the batteries to the inverter, allowing the stored solar energy to be used.

- Recreational vehicles (RVs): RVs use battery cables to connect multiple batteries, providing power for all the comforts of home while on the road.

In all these applications, the role of the battery cable is the same: to provide a reliable path for electrical current. Without it, you’re not going anywhere fast!

Understanding the basics of battery cables can help you appreciate the little things that keep your vehicle or other systems running smoothly. Next time you turn the key and your engine roars to life, you’ll know there’s more to it than meets the eye!

Comparing Flexibility

Comparing the flexibility of welding cables and battery cables reveals key differences. Flexibility is crucial for various applications. It affects how easily the cables can be maneuvered and installed. Let’s explore the flexibility of both types of cables.

Welding Cable Flexibility

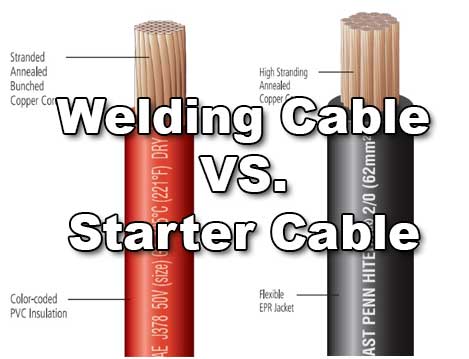

Welding cables are designed with high flexibility in mind. They need to withstand constant movement and bending. The copper strands in welding cables are finer and more numerous. This design helps the cable bend and flex without breaking. Welding cable insulation is also soft and pliable. This makes the cable easier to handle in tight spaces.

Welding cables are often used in industrial environments. They must endure tough conditions and remain flexible. This flexibility also helps reduce wear and tear on the cable. It extends the cable’s lifespan and reliability.

Battery Cable Flexibility

Battery cables are generally less flexible than welding cables. They have thicker copper strands and fewer of them. This makes the cable stiffer and less bendable. Battery cables are designed for stationary use. They typically connect to batteries and other components in fixed positions.

The insulation on battery cables is more rigid. This adds to the overall stiffness of the cable. Battery cables do not require the same level of flexibility. They are not moved or bent as frequently as welding cables. This design ensures a secure and stable connection for battery systems.

Credit: www.centralwires.com

Durability Factors

When it comes to selecting the right cable for your project, understanding the durability factors is crucial. You want something that can withstand the elements and the wear and tear of regular use. Let’s dive into the differences between welding cable and battery cable in terms of their durability. This will help you make an informed decision and ensure your project stands the test of time.

Environmental Resistance

One of the first things to consider is how well each type of cable can handle environmental factors.

- Welding Cable: Designed to endure extreme conditions, welding cables are typically made with EPDM (Ethylene Propylene Diene Monomer) insulation. This material is highly resistant to heat, cold, moisture, and even ozone. So, whether you are working in a blazing hot workshop or a freezing outdoor environment, welding cables are up for the challenge.

- Battery Cable: Battery cables usually have PVC (Polyvinyl Chloride) insulation, which is more susceptible to temperature fluctuations. While PVC does offer decent resistance to chemicals and abrasion, it doesn’t perform as well in extreme temperatures. If you are in a mild climate, battery cables can work fine, but they might struggle in more severe conditions.

Wear And Tear

Everyday wear and tear is another important aspect to consider when choosing between welding and battery cables.

- Welding Cable: The flexibility and toughness of welding cables make them highly resistant to abrasion. They are designed to be dragged across rough surfaces and withstand heavy mechanical stress. This makes them ideal for industrial environments where cables are constantly being moved and manipulated.

- Battery Cable: Battery cables, while sturdy, are not built to handle the same level of mechanical stress as welding cables. They are better suited for static applications where the cable doesn’t move much. If you need a cable that will stay put and last a long time, a battery cable might suffice. But for dynamic environments, welding cable is the way to go.

In conclusion, when it comes to durability, welding cables tend to outperform battery cables. They are more resistant to environmental factors and everyday wear and tear. So, if you’re looking for a cable that can handle tough conditions and constant movement, welding cable is your best bet. But if your needs are less demanding, a battery cable can be a reliable and cost-effective option. Choose wisely, and your project will thank you!

Current Carrying Capacity

Current carrying capacity is a key factor in choosing between welding cable and battery cable. The ability to carry current efficiently determines the performance of the cable. This section will explain the differences in current carrying capacities of welding and battery cables.

Welding Cable Capacity

Welding cables are designed to handle high currents. They are flexible and can carry large amounts of current without overheating. The fine copper strands in welding cables allow better conductivity. This means they can support higher current loads over short periods.

Battery Cable Capacity

Battery cables are designed for steady, consistent current flow. They are less flexible but still efficient. Battery cables typically have thicker copper strands. This design helps them carry moderate currents over longer periods without losing efficiency.

Insulation Differences

Understanding the insulation differences between welding cable and battery cable is crucial. Insulation affects performance, safety, and durability. Let’s dive into the specifics.

Welding Cable Insulation

Welding cables have robust insulation. They often use EPDM or neoprene. These materials resist heat, oil, and abrasion. This insulation allows welding cables to handle tough conditions. Flexibility is a key feature. It helps in maneuvering the cables during welding tasks.

Battery Cable Insulation

Battery cables have different insulation needs. They typically use PVC insulation. PVC provides good protection against acids and chemicals. It is less flexible than welding cable insulation. Battery cables do not need to be as flexible. They stay in one place, connecting the battery to the vehicle.

Cost Considerations

When choosing between welding cable and battery cable, one major factor to consider is the cost. While both types of cables serve important functions, their costs can vary significantly. In this section, we will delve into the cost differences between welding cable and battery cable to help you make an informed decision.

Welding Cable Cost

Welding cables can be a bit more expensive than battery cables. This is because welding cables are designed to handle more stress and higher currents. They are built with flexible, durable insulation and a high strand count, which makes them more robust and versatile.

Here are a few factors influencing the cost of welding cables:

- Material Quality: Higher quality materials typically result in higher prices.

- Insulation Type: More advanced insulation can increase the cost.

- Flexibility: More flexible cables often come at a premium.

- Length and Gauge: Longer and thicker cables will naturally cost more.

So, if you’re looking for a cable that can withstand tough conditions and provide high performance, welding cable is worth the investment. After all, you get what you pay for, right?

Battery Cable Cost

On the other hand, battery cables are generally more affordable. They are used for connecting batteries to electrical systems, and they don’t require the same level of flexibility or durability as welding cables.

The cost of battery cables is influenced by:

- Length: Shorter cables are cheaper.

- Gauge: Thinner cables are less expensive.

- Insulation: Basic insulation is usually sufficient, keeping costs down.

If you’re on a budget and need a cable for standard battery connections, battery cables are a cost-effective choice. They do the job without breaking the bank.

In conclusion, while welding cables are more expensive due to their superior build and flexibility, battery cables offer a more budget-friendly option for simpler tasks. Always consider the specific requirements of your project to determine which cable will provide the best value for your money.

Choosing The Right Cable

Choosing the right cable is crucial for any electrical project. Welding cables and battery cables may look similar, but they serve different purposes. Understanding these differences ensures optimal performance and safety.

Application Needs

Consider the cable’s purpose first. Welding cables are flexible and designed for high-current welding applications. They can handle rough conditions and constant movement. Battery cables, on the other hand, are used to connect batteries to electrical systems. They are less flexible but more suited for stationary setups.

Performance Requirements

Welding cables perform well under high temperatures and heavy loads. They are insulated with durable materials that resist heat, oil, and chemicals. Battery cables are built to provide consistent power delivery. They have thicker insulation to prevent voltage drops and ensure reliable connections.

Credit: www.wiringdepot.com

Frequently Asked Questions

Can I Use Welding Cable For Battery Cable?

Yes, you can use welding cable for battery cable. Welding cables are flexible, durable, and handle high currents well. Ensure proper gauge and insulation for safety.

What Is The Difference Between Battery Cable And Electrical Cable?

Battery cables are designed for high current, low voltage applications, typically in vehicles. Electrical cables handle various voltages and currents, used in broader applications like homes and industries.

What Is The Difference Between 2ga Welding Cable And 2ga Battery Cable?

2GA welding cable is more flexible and has a higher temperature rating. 2GA battery cable is stiffer and used for lower temperature applications.

Can You Use Welding Cable For Electrical Wiring?

Yes, you can use welding cable for electrical wiring. Ensure it meets the voltage and current requirements. It’s flexible and durable but check local codes for compliance.

Conclusion

Welding cable and battery cable serve different purposes. Welding cables handle high temperatures. They are flexible and durable. Battery cables connect power sources in vehicles. They are less flexible but sturdy. Each type has specific uses. Understanding these differences helps you choose the right cable.

Select based on your needs for safety and efficiency.