Welding helmets protect your face and eyes from sparks and bright light. They are essential for safety during welding.

But how do they actually work? Welding helmets are designed with special features to keep welders safe. They have darkened lenses to block harmful light and protect your eyes. Some helmets have auto-darkening filters that adjust the lens shade based on the welding arc’s brightness.

The helmet’s shell protects your face from flying debris and sparks. Understanding how these components work together can help you choose the right helmet and use it effectively. This knowledge ensures safety and improves your welding experience. Let’s dive deeper into the fascinating mechanics of welding helmets.

Introduction To Welding Helmets

When you hear the word “welding,” what comes to mind? Sparks flying, intense heat, and maybe a skilled welder creating something amazing out of metal. But there’s something you might not think about right away: the welding helmet. This essential piece of gear is more than just a fashion statement in the welding world. It’s a lifesaver. Let’s dive into the fascinating world of welding helmets.

Purpose Of Welding Helmets

The main job of a welding helmet is to protect the welder. Think of it as a superhero’s mask. It shields the welder’s face and eyes from the harmful effects of the welding process. Here’s why it’s crucial:

- Protection from UV and IR Radiation: Welding produces ultraviolet (UV) and infrared (IR) rays that can severely damage your eyes and skin.

- Prevents Burns: Sparks and spatter from welding can cause painful burns if they come in contact with your skin.

- Prevents Welder’s Flash: This is a painful condition caused by exposure to intense UV light, leading to a feeling similar to having sand in your eyes.

In essence, a welding helmet is your best buddy when it comes to safety in the welding environment.

Brief History

Let’s take a quick trip back in time. Welding helmets have come a long way. In the early days, welders had to make do with basic helmets made from leather. These provided some protection, but not much. Imagine trying to weld with just a piece of leather over your face. Not very effective, right?

Then came the invention of the passive welding helmet. This type of helmet had a fixed shade lens, usually a dark piece of glass. It was better than leather but still had its drawbacks. Welders had to lift the helmet to see their work and then flip it down when welding. This constant up-and-down motion was not only tiring but also unsafe.

Fast forward to the 1980s. The game-changer arrived: the auto-darkening welding helmet. This innovation was like switching from a horse-drawn carriage to a sports car. It automatically adjusted the lens shade based on the intensity of the light from the welding arc. No more flipping the helmet up and down. It was a revolution in safety and convenience.

Today’s welding helmets are high-tech marvels. They come with features like adjustable shade settings, comfortable headgear, and even built-in ventilation systems. Some models are so advanced; they might make you feel like Iron Man!

To sum up, welding helmets have evolved significantly over the years, making the welding process not only safer but also more efficient. Whether you’re a seasoned welder or just starting, understanding the importance and history of welding helmets can give you a greater appreciation for this critical piece of equipment.

So, next time you see a welder at work, remember the unsung hero on their head – the welding helmet. It’s not just a piece of gear; it’s a lifesaver.

Types Of Welding Helmets

Welding helmets are essential for protecting your eyes and face during welding. They shield you from harmful light and flying debris. Various types cater to different needs and preferences. Let’s explore the main types of welding helmets.

Passive Welding Helmets

Passive welding helmets have a fixed shade lens. This lens is usually dark. You need to lift the helmet to see your work. Then, lower it before striking the arc. These helmets are durable and less expensive. They are ideal for simple and repetitive tasks.

Auto-darkening Helmets

Auto-darkening helmets have lenses that adjust automatically. They darken when you start welding. The lens is clear when inactive. This feature offers convenience and protection. You don’t need to lift and lower the helmet constantly. Auto-darkening helmets are more advanced. They suit various welding tasks. They provide comfort and efficiency.

Components Of A Welding Helmet

Welding helmets are vital for safety in welding. They protect your face and eyes from harmful light and sparks. Let’s break down the main components that make up a welding helmet. Understanding these parts can help you choose the right helmet for your needs.

Helmet Shell

The helmet shell is the outer part. It shields your head from flying debris and sparks. It is usually made from durable materials like fiberglass or plastic. This ensures it can withstand high temperatures and rough conditions. The shell also helps in blocking harmful UV and infrared rays.

Lens And Filters

The lens is the most crucial part of the helmet. It protects your eyes from intense light and radiation. There are different types of lenses available. Fixed shade lenses have a constant level of darkness. Auto-darkening lenses adjust automatically to light changes. Filters work with the lens to enhance clarity and protect against radiation.

Headgear

The headgear keeps the helmet in place. It is adjustable to fit different head sizes. Comfortable padding is often included to ensure a snug fit. The headgear also helps distribute the weight of the helmet evenly. This reduces strain on your neck and shoulders.

Understanding these components will help you better appreciate the importance of each part. This knowledge ensures you can make informed decisions about your welding helmet.

Credit: www.apexweldingsafety.com.au

The Science Behind Auto-darkening Helmets

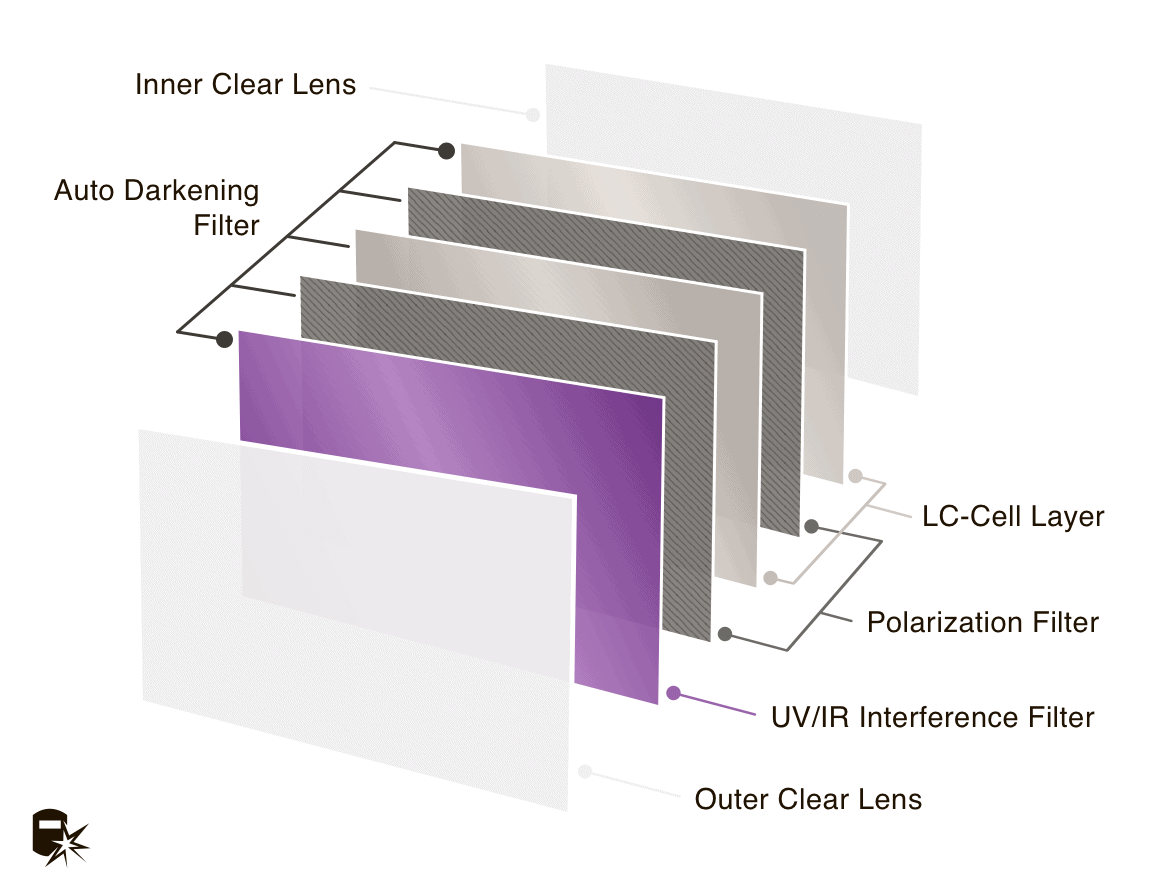

Auto-darkening welding helmets use sensors to detect the light from welding arcs. This triggers a liquid crystal display (LCD) to darken and protect the welder’s eyes. The technology ensures safety and convenience by automatically adjusting the lens shade.

Auto-darkening helmets protect welders’ eyes from bright light. These helmets use advanced technology to adjust the lens darkness automatically. This ensures safety and comfort during welding.Liquid Crystal Technology

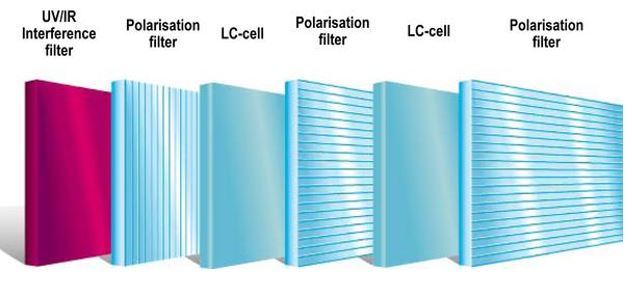

Auto-darkening helmets use liquid crystal technology. The lens has layers of liquid crystal cells. These cells change their orientation when voltage is applied. This change affects the light passing through the lens. When no voltage is present, the lens remains clear. When a welding arc starts, the sensors detect it. They send a signal to apply voltage to the liquid crystals. The lens darkens instantly. This protects the welder’s eyes from the bright light.Sensor Mechanism

The sensor mechanism plays a crucial role. Auto-darkening helmets have light sensors. These sensors detect the welding arc’s brightness. They send signals to the control unit. The control unit adjusts the lens darkness. This happens in milliseconds. The sensors ensure the lens darkens only during welding. When the welding stops, the lens returns to clear. This quick response provides continuous protection. The sensors also adapt to different light conditions. This makes auto-darkening helmets versatile and reliable. “`Safety Features In Welding Helmets

Welding helmets are essential for protecting welders from various hazards. These helmets are not just for shielding eyes from bright light. They come with multiple safety features to ensure maximum protection. Let’s look at some key features that make welding helmets safe.

Uv/ir Protection

Welding helmets provide excellent UV/IR protection. They block harmful ultraviolet and infrared rays. This prevents damage to the eyes and skin. The lenses in the helmets are specially coated. They filter out these dangerous rays effectively. Even during the brightest welds, your eyes stay safe.

Impact Resistance

Welding helmets are designed to withstand impacts. They protect the face from flying debris and sparks. The outer shell is made of durable materials. This ensures it can handle harsh conditions. Impact resistance is crucial for safety in welding environments. A strong helmet can prevent serious injuries.

Proper Usage And Maintenance

Welding helmets are essential for protecting your eyes and face during welding tasks. However, just owning one isn’t enough. To get the most out of your helmet, you need to use and maintain it properly. Let’s dive into the details of proper usage and maintenance to keep your helmet in top shape and ensure your safety.

Wearing The Helmet Correctly

Wearing your welding helmet correctly is crucial. An improperly worn helmet can lead to serious injuries. First, adjust the headgear to fit snugly. It shouldn’t be too tight or too loose. You want it to stay in place without causing discomfort.

Next, position the helmet so the lens is directly in front of your eyes. This gives you a clear view of your work. If the helmet has an adjustable lens shade, set it to the right level for the type of welding you’re doing. A darker shade is needed for higher amperage welding.

Remember to lower the helmet before you start welding. It may sound obvious, but in the heat of the moment, it’s easy to forget. Lowering the helmet protects your eyes from harmful UV and IR rays emitted during welding.

Cleaning And Storage

Keeping your welding helmet clean and stored properly extends its lifespan and ensures it functions correctly. After each use, wipe the helmet with a soft, damp cloth to remove dust and debris. Avoid using harsh chemicals as they can damage the lens and the helmet’s surface.

Pay special attention to the lens. Clean it gently to avoid scratches. If the lens is severely scratched or damaged, replace it immediately. A clear lens is vital for visibility and protection.

When it comes to storage, keep your helmet in a cool, dry place. Avoid leaving it in direct sunlight or in a humid environment. Both can degrade the materials over time. A dedicated helmet bag or a clean, dry shelf works well for storage.

Here are some quick tips for maintenance:

- Regularly check for cracks or damage.

- Replace worn-out parts promptly.

- Ensure the headgear adjustment mechanism works smoothly.

- Keep spare lenses and parts handy.

Proper usage and maintenance not only keep your welding helmet in good condition but also ensure your safety during welding tasks. By following these simple steps, you can enjoy a safer and more efficient welding experience.

Selecting The Right Welding Helmet

Choosing the right welding helmet is important for both safety and efficiency. A well-suited helmet can protect your eyes and face from harmful rays and sparks. It also allows you to work more comfortably and see your workpiece clearly. This section will help you understand the key factors to consider and common mistakes to avoid.

Factors To Consider

Several factors play a role in selecting the right welding helmet. First, consider the type of lens. Auto-darkening lenses are popular as they adjust to light changes. Fixed-shade lenses are simpler but less versatile.

Next, check the helmet’s weight. A lightweight helmet reduces strain on your neck and shoulders. Comfort is also essential. Look for adjustable headgear and padded bands.

Visibility is another factor. A larger viewing area allows a better view of your work. Some helmets offer side windows for an even wider field of vision. Also, lens clarity is crucial. Higher optical ratings provide a clearer and less distorted view.

Finally, consider the helmet’s power source. Solar-powered helmets are low-maintenance. Battery-powered ones may require more attention but often last longer.

Common Mistakes To Avoid

A common mistake is choosing a helmet based on price alone. Cheaper helmets may not offer the protection and features you need.

Another error is ignoring the helmet’s fit. A poor fit can lead to discomfort and distraction. Always try the helmet on before buying.

Some welders overlook the importance of adjustable settings. A helmet with customizable sensitivity and delay controls improves performance.

Do not forget to check the warranty. A good warranty provides peace of mind and ensures support if something goes wrong.

Avoid helmets without proper safety certifications. Certified helmets meet standards for eye and face protection.

Credit: www.youtube.com

Future Innovations In Welding Helmets

The welding industry constantly evolves with new technologies. Welding helmets are no exception. They have advanced significantly. Future innovations promise even more exciting features. These improvements will enhance safety and comfort for welders.

Advanced Technologies

Future welding helmets will use cutting-edge technologies. They will feature augmented reality (AR) displays. AR can provide real-time data. This data will guide welders for precision work. Helmets will also incorporate artificial intelligence (AI). AI can adjust settings automatically. This ensures optimal protection at all times.

Another exciting technology is the integration of sensors. Sensors can monitor environmental conditions. They can detect harmful gases or extreme temperatures. These features will alert welders to potential dangers. This real-time monitoring increases overall safety.

Enhanced Safety Features

Future welding helmets will have enhanced safety features. One key feature is advanced lens technology. The lenses will offer better clarity. This reduces eye strain and improves focus. Auto-darkening lenses will become more responsive. They will adjust faster to changing light conditions.

Lightweight materials will also be used. These materials will provide better comfort without sacrificing protection. Improved ventilation systems will keep welders cool. This reduces fatigue during long hours of work.

Additionally, future helmets will have better fit and adjustability. This ensures a snug fit for all head sizes. Proper fit prevents exposure to harmful radiation and sparks.

Credit: weldguru.com

Frequently Asked Questions

Does Welding Hurt Your Eyes Even With A Welding Helmet?

Welding can hurt your eyes even with a helmet if the helmet is not properly rated or used incorrectly. Always ensure your helmet meets safety standards and fits well to provide adequate protection.

How Does A Welding Helmet Protect You?

A welding helmet shields your eyes and face from harmful UV and infrared rays. It protects against sparks, heat, and bright light. The helmet’s auto-darkening feature adjusts the lens shade, ensuring clear vision and safety during welding. This essential gear prevents eye injuries and skin burns.

What Do Welders Wear Under Their Helmets?

Welders wear flame-resistant balaclavas or welding caps under their helmets. These protect their heads and necks from sparks and heat.

What Are The Rules For Welding Helmets?

Welding helmets must meet ANSI Z87. 1 standards. Ensure proper fit and comfort. Use appropriate shade lenses for eye protection. Maintain and inspect regularly for damage. Always wear during welding to prevent eye injuries.

Conclusion

Understanding how welding helmets work helps ensure safety and precision. These helmets protect your eyes and face from harmful UV rays. The auto-darkening feature adjusts to the brightness instantly. Comfortable and adjustable designs make wearing them easy. Choosing the right helmet enhances welding performance.

Always prioritize safety and comfort in your selection. Remember to regularly maintain your helmet for optimal performance. With the right knowledge, welding becomes safer and more efficient. Stay informed, stay safe, and happy welding!