Choosing the best welding table size is crucial for every welder. The right size ensures efficiency and safety.

A welding table is a vital tool in any welder’s workspace. It provides a stable surface to work on various projects, from small repairs to larger fabrications. Selecting the right size can impact your workflow and the quality of your welds.

Whether you are a hobbyist or a professional, the size of your welding table should match your specific needs and space. In this post, we will explore different welding table sizes, their benefits, and how to choose the perfect one for your tasks. Let’s dive into the details to help you make an informed decision.

Credit: rathasochenda.com

Importance Of Welding Table Size

The size of your welding table plays a vital role in your work. A well-sized table can make a world of difference. This affects both efficiency and safety. Understanding the importance of welding table size can help you make the right choice.

Maximizing Efficiency

A properly sized welding table boosts your work efficiency. A larger table provides ample space for your projects. This allows you to work without feeling cramped. You can lay out tools and materials within easy reach. This reduces the time spent searching for items. Less time searching means more time welding. A spacious table also helps in organizing your workspace better. This results in a smoother workflow.

Ensuring Safety

Safety is paramount in welding. The right table size contributes to a safer work environment. A stable and spacious table minimizes the risk of accidents. It prevents tools and materials from falling off. This can reduce the chances of injuries. A larger table also provides a better surface for clamping your work. Secure clamping means fewer mishaps during welding. Ensuring you have enough space to move around the table is crucial. It reduces the risk of tripping or bumping into objects.

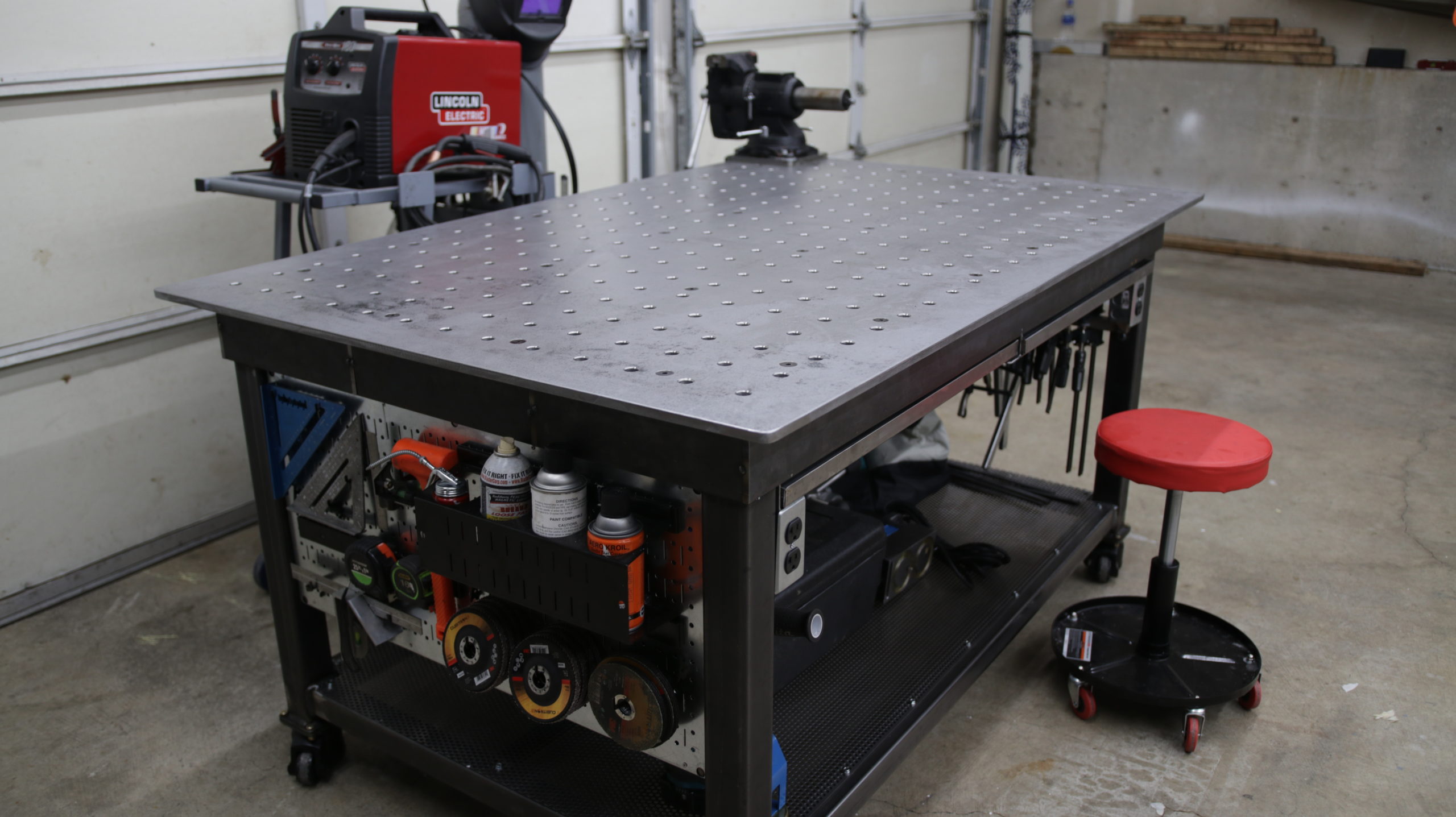

Credit: theweldspace.co.uk

Assessing Your Workshop Space

Choosing the right welding table size involves many factors. One key factor is the size of your workshop space. A proper assessment ensures a good fit and smooth workflow. Let’s break this down.

Measuring Available Area

First, measure your workshop area. Use a tape measure to get the length and width. Write down these measurements. Ensure to account for any obstacles like walls or cabinets. This will help you understand your usable space.

Next, consider the height of your welding table. Make sure it fits well within your workspace. A table that is too tall or too short can cause discomfort. It can also lead to poor work quality. So, choose a height that suits your needs.

Considering Workflow

Think about your workflow. How do you move around your workshop? Is there enough room to walk around the table? Ensure you can access all sides of the table. This helps in working on large projects.

Also, consider the placement of other equipment. You don’t want your welding table to block access to tools. Make sure there is enough space for everything. This will help maintain an efficient workflow.

Types Of Welding Tables

Choosing the right welding table can be as crucial as selecting the right welding machine. Whether you are a hobbyist, a DIY enthusiast, or a professional welder, understanding the different types of welding tables will help you make an informed decision. Let’s dive into the two main categories: fixed vs. portable and adjustable options.

Fixed Vs. Portable

When it comes to welding tables, one of the first decisions you will need to make is whether you want a fixed or a portable table. Both have their perks and pitfalls.

- Fixed Welding Tables: These tables are designed to stay in one place. They are typically heavier and more robust. If you have a dedicated workspace, a fixed table can provide a stable and sturdy surface, which is essential for precision welding. Think of it like the sturdy workbench in your grandpa’s garage – reliable and always there when you need it.

- Portable Welding Tables: On the other hand, portable welding tables are designed for flexibility. These tables are lighter and often come with foldable legs, making them easy to transport. If you need to move your workspace frequently or work on-site, a portable table is your best friend. Picture it as the Swiss Army knife of welding tables – versatile and ready to go wherever you are.

Adjustable Options

Adjustability can be a game-changer when it comes to welding tables. Adjustable tables allow you to modify the height and sometimes even the angle of the table, providing a comfortable working position.

- Height Adjustable Tables: These tables come with mechanisms to adjust the height. Whether you are tall or short, you can set the table to a height that suits you, reducing strain on your back and improving your posture. Imagine being able to customize your workspace to fit you perfectly – it’s like having a tailor-made suit.

- Angle Adjustable Tables: Some advanced welding tables offer the option to adjust the angle of the tabletop. This feature is particularly useful when working on complex projects that require precise angles. It’s like having a magic wand that lets you tilt your workspace to the perfect angle.

In conclusion, whether you opt for a fixed, portable, or adjustable welding table, the key is to find one that meets your specific needs. Consider your workspace, the types of projects you will be working on, and your personal preferences. Happy welding!

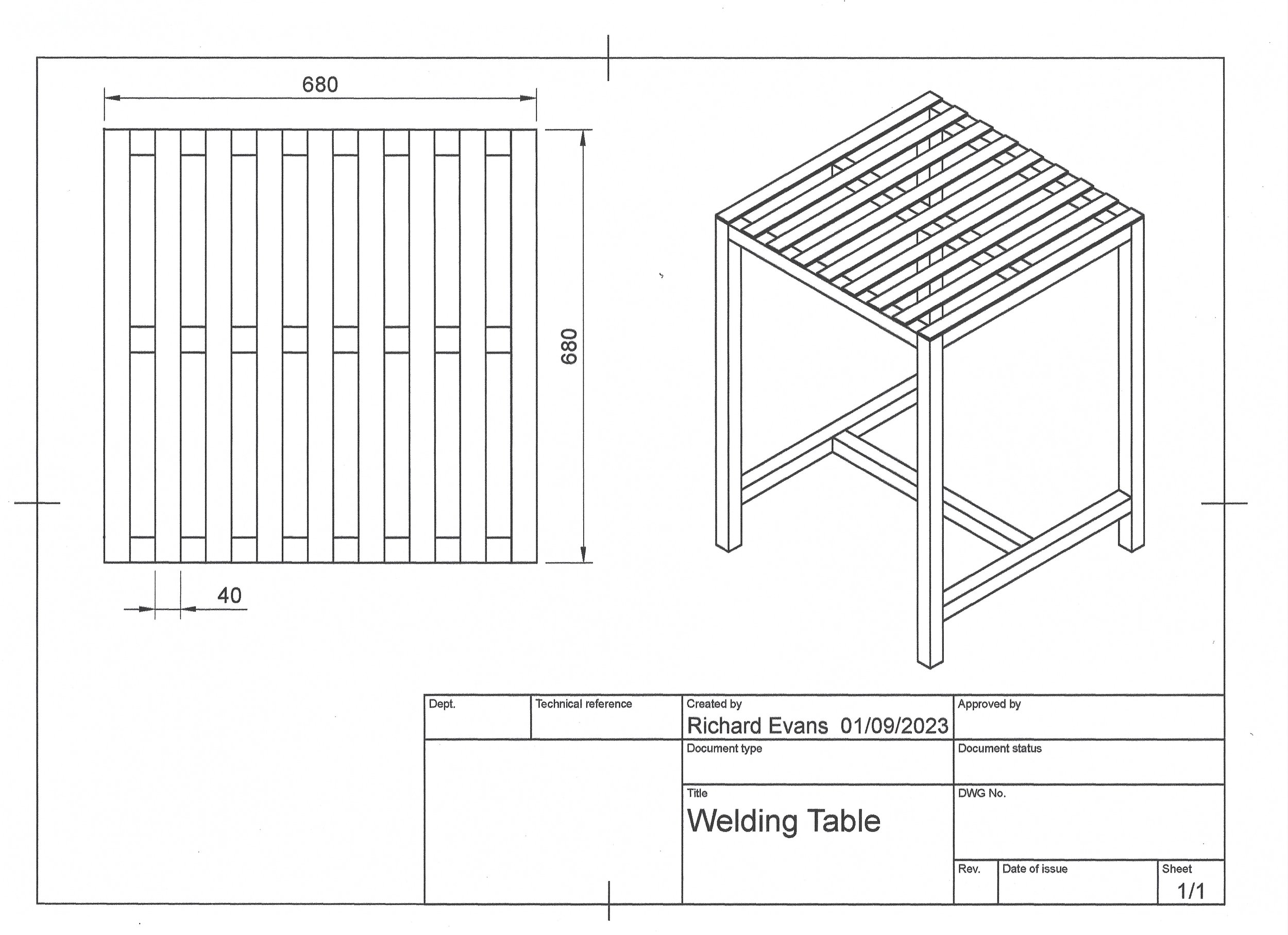

Credit: swsltd.co.nz

Standard Welding Table Dimensions

If you have ever tried welding, you know how important a good welding table is. It’s like your best friend in the workshop. But, what size should it be? That’s a question many beginners and even some seasoned welders ask. Let’s dive into the standard welding table dimensions to find out what works best for you.

Common Sizes

When it comes to welding tables, there’s no one-size-fits-all answer. However, there are some common sizes that most people use:

- 2 feet by 3 feet: This size is great for small projects. It’s also good if you don’t have much space in your workshop.

- 3 feet by 4 feet: A bit bigger, this size gives you more room to work. It’s a popular choice for hobbyists.

- 4 feet by 6 feet: This is a common size in professional shops. It offers plenty of space for larger projects.

Industry Recommendations

Now, let’s talk about what the pros recommend. Industry standards can give us a good idea of what works best in different situations.

- Height: Most welding tables are about 36 inches tall. This height is comfortable for most people to work at while standing.

- Thickness: The table top is usually 3/8 inch to 1/2 inch thick. A thicker top can handle more weight and heat.

- Material: Steel is the preferred material for welding tables. It’s durable and can take a lot of abuse.

So, what size should you choose? Think about what you will be welding. Small projects don’t need a huge table, but larger projects will require more space. Also, consider your workshop space. You need to be able to move around comfortably.

Remember, a good welding table is an investment. It’s worth spending a little extra to get one that will last and make your work easier. Happy welding!

Customizing Your Welding Table

When it comes to welding tables, one size certainly does not fit all. Every welder has unique needs, and customizing your welding table can make your job easier and more efficient. But where do you start? How do you ensure that your table matches your specific requirements? Let’s dive into the details.

Tailoring To Specific Needs

First things first, think about what you need from your welding table. Are you working on small, delicate projects, or are your tasks larger and more industrial? The size of your table should reflect the size and type of your projects.

- Small Projects: For smaller, intricate tasks, a compact table around 2×3 feet might be ideal. This size offers enough space to work while keeping your tools within easy reach.

- Medium Projects: If you’re handling medium-sized tasks, a table that is 4×4 feet can provide ample workspace without overwhelming your shop area.

- Large Projects: For large, heavy-duty projects, you might need a table that’s 5×8 feet or even larger. This size ensures you have the room to maneuver and work on extensive welds.

Remember, it’s not just about the size. Consider the table’s height too. A comfortable working height can reduce strain and improve your posture, making long welding sessions more manageable.

Diy Vs. Professional Builds

Now, the big question: should you build your own welding table or buy a professional one? Each option has its pros and cons, and your choice will depend on your skills, budget, and needs.

- DIY Builds: Building your own table can be a rewarding project. You get to customize every aspect, from size to material. Plus, it can be cost-effective. However, it requires a good set of tools and some welding experience. Not to mention, it can be time-consuming.

- Professional Builds: On the other hand, buying a professional welding table means you get a high-quality, ready-to-use product. These tables are designed with precision and often come with additional features like adjustable legs or built-in clamps. The downside? They can be pricey.

Consider your priorities. Do you enjoy hands-on projects and have the time to spare? A DIY build could be a fun challenge. But if you need something reliable and ready to go, investing in a professional table might be the better route.

| Aspect | DIY Build | Professional Build |

|---|---|---|

| Customization | High | Medium |

| Cost | Lower | Higher |

| Time Investment | High | Low |

| Quality | Variable | Consistent |

Whether you go the DIY route or opt for a professional build, the key is to choose a welding table that suits your specific needs and enhances your workflow. Take your time to assess what works best for you, and happy welding!

Material Considerations

Choosing the right material for your welding table is crucial. The material affects durability and heat resistance. These factors influence the table’s lifespan and performance. Let’s explore some key material considerations.

Durability

Your welding table should withstand heavy use. Strong materials like steel are ideal. They offer high resistance to wear and tear. Steel tables can support heavy weights and resist dents. This ensures a stable work surface for years.

Heat Resistance

Welding generates a lot of heat. Your table must handle this heat without warping. Heat-resistant materials like stainless steel are excellent. They maintain their shape and integrity under high temperatures. This is essential for accurate and safe welding.

Accessories And Add-ons

When it comes to optimizing your welding table, the right accessories and add-ons can make a world of difference. Whether you’re a seasoned welder or just getting started, these tools can significantly enhance your productivity and precision. In this section, we’ll delve into some essential accessories that can elevate your welding experience to the next level.

Clamps And Vises

Clamps and vises are the bread and butter of any welding table setup. They hold your workpieces securely in place, allowing you to work with both hands free. Imagine trying to weld a piece of metal without it moving around – frustrating, right? Here are some types you might consider:

- Toggle Clamps: These are easy to use and provide a strong hold. Perfect for repetitive tasks.

- C-Clamps: Versatile and robust, ideal for various welding projects.

- Bench Vises: These are great for holding larger pieces and can swivel, giving you more flexibility.

Investing in high-quality clamps and vises can save you time and ensure your welds are precise and clean. Trust me, your future self will thank you!

Storage Solutions

Let’s talk storage. Keeping your workspace tidy isn’t just about aesthetics; it’s about efficiency and safety. A cluttered table can lead to accidents and wasted time searching for tools. Here are some storage solutions to consider:

- Tool Racks: These keep your frequently used tools within reach. No more digging through drawers!

- Drawers and Cabinets: Ideal for storing smaller tools and accessories, keeping them dust-free and organized.

- Magnetic Strips: Attach these to the side of your table to hold metal tools and accessories securely.

By integrating efficient storage solutions, you can keep your welding area clean and organized, which can significantly improve your workflow.

Remember, the right accessories can transform your welding table from a simple workbench into a powerhouse of productivity. So, invest wisely and watch your welding projects soar to new heights!

Budgeting For Your Welding Table

When it comes to buying a welding table, budgeting is a crucial step. Understanding the cost and value of different sizes can save you money and headaches down the road. Whether you’re a hobbyist or a professional, making a smart investment in your welding table is essential. Let’s dive into how you can budget effectively for your welding table, ensuring you get the best bang for your buck.

Cost Vs. Value

It’s easy to get caught up in the initial price tag of a welding table, but let’s not forget the age-old saying: “You get what you pay for.” Sure, you can find a cheaper table, but will it stand the test of time? Here are a few points to consider:

- Material Quality: A table made from high-quality steel may cost more upfront, but it will last longer and handle more wear and tear.

- Size and Versatility: A larger table might seem like an unnecessary expense, but if you’re working on bigger projects, it’s a wise investment.

- Features: Consider tables with built-in clamps, adjustable legs, and other features that can make your work easier and more efficient.

Remember, sometimes spending a little more can save you a lot in the long run. Think about the value the table will bring to your work, not just the cost.

Long-term Investment

Investing in a welding table is like investing in a good pair of shoes. It might pinch your wallet at first, but the comfort and durability pay off over time. Here’s why:

- Durability: A well-made welding table can last for years, even decades. It’s a one-time investment that keeps on giving.

- Increased Productivity: A sturdy, reliable table can make your work faster and more precise. No more wobbling or adjusting mid-weld.

- Safety: A high-quality welding table reduces the risk of accidents. It provides a stable and secure surface for your projects.

Think about it: wouldn’t you rather buy one good table than several cheap ones? It’s not just about the money; it’s about peace of mind. When you know your table is up to the task, you can focus on what you do best – welding.

So, whether you’re just starting out or looking to upgrade, take the time to budget wisely for your welding table. Your future self will thank you for it!

Frequently Asked Questions

What Is The Best Size For A Welding Table?

The best size for a welding table is typically 4 feet by 8 feet. This size offers ample space for most projects.

What Makes A Good Welding Table?

A good welding table is sturdy, made of steel, and has a flat, heat-resistant surface. It should have adjustable height, proper ventilation, and ample clamping options. Storage for tools and accessories is a bonus.

What Is The Best Plate Thickness For A Welding Table?

The best plate thickness for a welding table is 3/8 to 1/2 inch. This thickness ensures durability and stability.

What Is The Best Surface For A Welding Table?

The best surface for a welding table is thick, flat steel. It withstands high heat and provides a sturdy work area.

Conclusion

Choosing the right welding table size makes a big difference. It improves your work efficiency and safety. Consider your workspace and the type of projects you do. A well-sized table helps you stay organized. It also provides enough room for your tools.

Think about mobility if you need to move it often. Always measure your space before buying. This simple step saves you trouble later. Make the right choice for a better welding experience.