Calculating welding thickness is essential for ensuring strong and safe welds. Understanding this process can help you achieve better results in your welding projects.

Welding thickness impacts the strength and durability of the final product. Knowing how to calculate it can save you time and prevent costly mistakes. Whether you’re a beginner or have some experience, learning this skill is crucial. This guide will walk you through the basic steps and considerations for calculating welding thickness, helping you improve your welding skills and outcomes.

By the end, you’ll have a clear understanding of the factors involved and be able to apply this knowledge to your projects. Let’s dive in and explore how to calculate welding thickness effectively.

Introduction To Welding Thickness

Welding is a crucial part of many projects, from building bridges to creating art. One key element in welding is getting the thickness right. But why is welding thickness so important? And how do you measure it accurately? Let’s dive into the basics and learn more!

Importance Of Accurate Measurement

When it comes to welding, precision is everything. Imagine building a structure and having the welds fail because they are too thin. Not a pretty picture, right? Accurate measurement ensures safety and durability.

- Safety: Incorrect thickness can lead to weak spots in the weld, which might cause accidents.

- Durability: Proper thickness contributes to the longevity of the welded structure.

- Compliance: Many industries have strict standards for welding thickness.

Common Applications

Welding thickness is not just for big, industrial projects. It’s used in many everyday applications too. Here are a few:

- Construction: From skyscrapers to homes, welding is fundamental.

- Automotive: Cars, trucks, and even bikes rely on precise welding.

- Art: Sculptors use welding to create lasting pieces.

- Manufacturing: Many products you use daily are welded.

Have you ever wondered how your bicycle stays intact or why your car is so safe? It’s all thanks to the right welding thickness!

Credit: www.youtube.com

Basic Principles Of Welding Thickness

The basic principles of welding thickness are crucial for achieving strong and durable welds. Understanding these principles helps ensure safety and structural integrity in welded joints. It involves considering various factors like material type, thickness, and the relationship between thickness and strength. These principles guide welders in selecting the correct welding technique and parameters for different materials and thicknesses.

Material Considerations

Different materials react differently to welding. Metals like steel, aluminum, and copper have unique properties. These properties affect how they are welded. For instance, steel is strong and durable. It requires higher heat for welding. Aluminum, on the other hand, is softer. It melts at lower temperatures. Knowing the material type helps in choosing the right welding method.

Thickness And Strength Relationship

The thickness of the material impacts the strength of the weld. Thicker materials generally need more heat and stronger welds. This ensures the joint can support the intended loads. Conversely, thinner materials require less heat. Excessive heat can cause warping or burn-through. Thus, balancing heat input with material thickness is key to a strong weld.

Tools For Measuring Welding Thickness

Accurate welding thickness measurements ensure the strength and durability of welded structures. Choosing the right tools is crucial for achieving precise results. Let’s explore some essential tools for measuring welding thickness.

Calipers And Micrometers

Calipers are versatile tools, used for measuring internal and external dimensions. They are easy to handle and provide quick results. They come in digital and manual versions. Use calipers for simple and quick thickness checks.

Micrometers offer higher accuracy compared to calipers. They measure thickness in small increments, often up to thousandths of an inch. Micrometers are ideal for detailed welding thickness measurements.

Ultrasonic Thickness Gauges

Ultrasonic thickness gauges are advanced tools. They use sound waves to measure material thickness without damaging the surface. These gauges are suitable for measuring thickness in hard-to-reach areas.

Ultrasonic gauges offer precise readings and are easy to use. They are especially useful for inspecting large welded structures and ensuring uniform thickness.

Step-by-step Welding Thickness Calculation

Calculating welding thickness might seem like a tricky task, but with the right steps, it becomes much easier. Let’s break it down into simple steps so that even beginners can understand and perform it efficiently. Ready to dive in? Let’s go!

Preparation And Safety

Before you start calculating, it’s vital to prepare properly and ensure safety. Safety is paramount in any welding task. Here’s what you need to do:

- Wear Protective Gear: Always wear gloves, a welding helmet, and protective clothing to shield yourself from sparks and intense light.

- Clear the Area: Make sure your workspace is clean and free of any flammable materials. This reduces the risk of accidents.

- Inspect Equipment: Check your welding equipment for any damages or malfunctions. A well-maintained tool is a safe tool.

Once you’re geared up and the area is prepped, you’re ready to move on to the measurement techniques.

Measurement Techniques

Now that you’re prepared and safe, let’s get into measuring the welding thickness. Accurate measurements are crucial for a strong weld. Here’s how you can measure it effectively:

- Use a Caliper: A caliper is a precise tool that can measure the thickness of the metal. Place the caliper at the edge of the metal and read the measurement.

- Welding Gauge: A welding gauge is another handy tool. Simply place the gauge on the weld and check the readings. It gives you a quick and accurate measurement.

- Micrometer: For more precise measurements, a micrometer can be used. It works similarly to a caliper but offers higher precision.

Remember, practice makes perfect. The more you practice these techniques, the better you’ll get at measuring welding thickness accurately.

So there you have it! A simple guide to calculating welding thickness. Stay safe, measure accurately, and happy welding!

Advanced Techniques For Accurate Measurement

Accurate measurement of welding thickness is crucial for ensuring the quality and safety of your welds. Advanced techniques can help you achieve precise results, saving time and reducing waste. Let’s explore some effective methods for measuring welding thickness.

Using Digital Tools

Digital tools offer high precision and ease of use. Devices like digital calipers and ultrasonic thickness gauges provide accurate readings. These tools minimize human error and offer quick results. Digital calipers measure the external dimensions of the weld. Ultrasonic gauges, on the other hand, can measure internal thickness without damaging the material. Investing in these tools can significantly improve your measurement accuracy.

Calibration And Validation

Calibration ensures that your measuring tools provide accurate readings. Regularly calibrate your devices according to the manufacturer’s instructions. This practice helps maintain the reliability of your measurements. Validation involves cross-checking your measurements with standard references or known values. Use calibration blocks or reference materials to validate your readings. Consistent calibration and validation routines help maintain measurement accuracy over time.

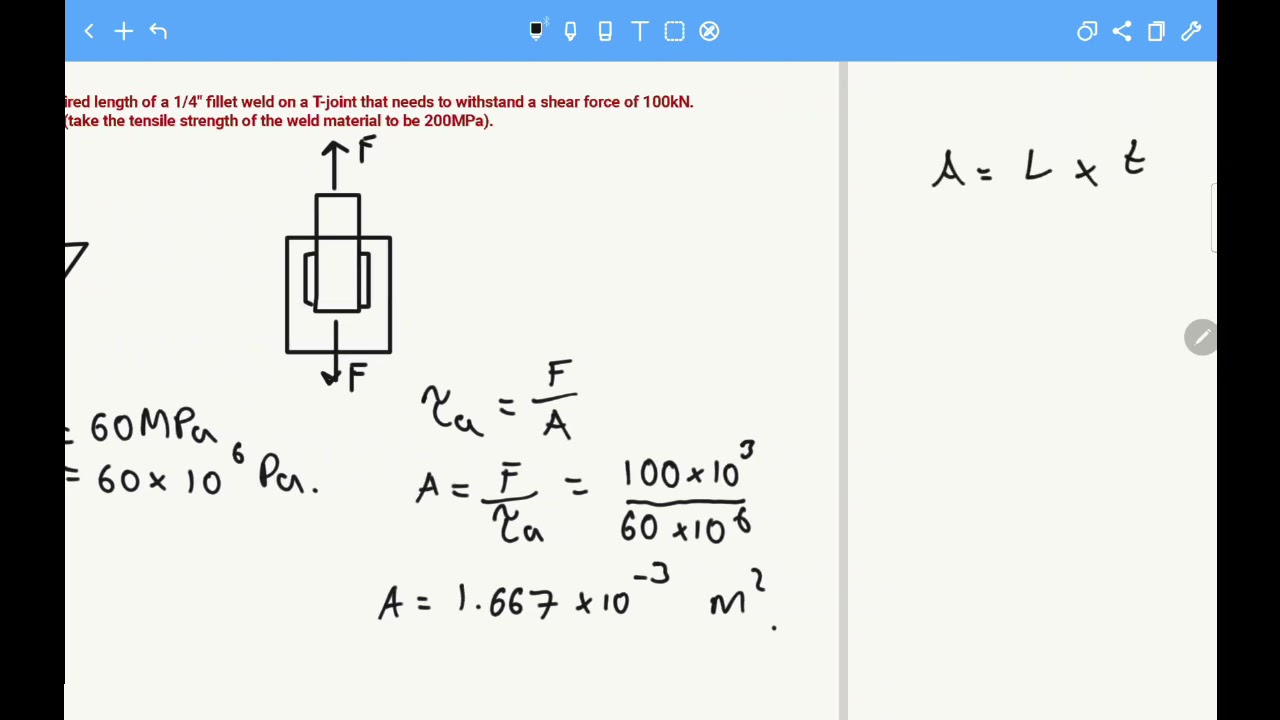

Credit: www.weldingandndt.com

Common Mistakes To Avoid

Calculating welding thickness can be tricky, even for seasoned welders. Mistakes are common, but knowing what to watch out for can save you time and effort. Let’s dive into some typical errors and how you can avoid them.

Misreading Measurements

One of the most frequent mistakes is misreading measurements. Imagine spending hours welding, only to find out that your measurements were off. Frustrating, right? Here are some tips to avoid this:

- Double-check your tools: Always ensure your measuring tools are calibrated and functioning properly.

- Use the right units: Don’t mix up millimeters and inches. It’s a common error that can lead to significant problems.

- Take multiple readings: Measure more than once to confirm accuracy. A second or third check can make all the difference.

Ignoring Material Variances

Different materials behave differently under heat. Ignoring these variances can compromise the quality of your weld. Here’s how to stay on top of it:

- Know your material: Always check the specifications of the material you’re working with. Steel, aluminum, and titanium all require different approaches.

- Adjust your technique: Be prepared to adjust your welding technique based on the material. Some metals may expand more than others, affecting the final thickness.

- Consult the experts: When in doubt, ask for advice. Experienced welders or material scientists can provide valuable insights.

By avoiding these common mistakes, you’ll improve your welding accuracy and produce better results. Remember, careful planning and attention to detail go a long way in welding. Happy welding!

Industry Standards And Guidelines

When it comes to calculating welding thickness, industry standards and guidelines are crucial. They help ensure that the welds are strong, safe, and fit for purpose. Following these standards can be the difference between a successful project and a failed one. Let’s dive into some key standards and best practices that can guide you in determining the correct welding thickness.

Astm And Iso Standards

Two of the most respected bodies that set the standards for welding are ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). These organizations provide detailed guidelines on how to measure and calculate welding thickness.

- ASTM Standards: ASTM has a range of standards related to welding, including ASTM E290, which covers the bend testing of material thickness. This standard helps determine the ductility and soundness of welded joints.

- ISO Standards: ISO also offers comprehensive standards like ISO 5173, which outlines the methods for testing the tensile strength of welds. This ensures that the weld can withstand the forces it will encounter during its service life.

Adhering to these standards not only ensures the safety and durability of your welds but also helps in maintaining consistency and quality across different projects. Trust me, you don’t want to be the person who cuts corners on these standards – it can lead to disastrous results!

Best Practices

While standards are essential, following best practices can make your life much easier. Here are some tips to help you calculate welding thickness effectively:

- Understand Your Material: Different materials require different welding techniques and thicknesses. For instance, welding aluminum is not the same as welding steel.

- Consult the Manufacturer’s Guidelines: Always refer to the manufacturer’s recommendations for the specific welding equipment and materials you are using. They often provide detailed instructions and thickness guidelines.

- Use Proper Measuring Tools: Invest in quality measuring tools such as calipers and micrometers. These tools will help you get accurate measurements, which are crucial for calculating the correct welding thickness.

- Practice Makes Perfect: Don’t be afraid to practice on scrap pieces. It’s better to make mistakes on a test piece than on your final project. Plus, practice helps you get a feel for the material and the welding process.

Remember, taking the time to follow these best practices can save you from a world of headaches down the line. Plus, you’ll end up with a weld that not only meets industry standards but also stands the test of time.

So, there you have it! By following these industry standards and best practices, you’ll be well on your way to calculating welding thickness like a pro. Happy welding!

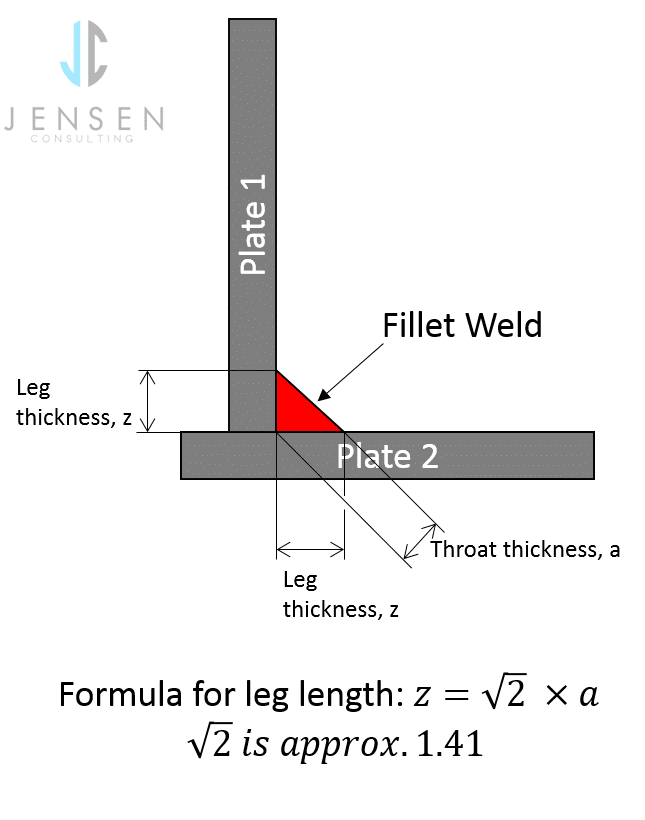

Credit: restoric.co.uk

Practical Tips From Experts

Calculating welding thickness can be challenging without the right guidance. Expert tips can make this process easier and more accurate. Here are some practical tips from experts to help you calculate welding thickness more effectively.

Maintaining Equipment

Regular maintenance of welding equipment is crucial. Well-maintained equipment ensures accurate measurements. Clean and calibrate your tools often. This helps to avoid errors in welding thickness calculations. Faulty equipment can lead to incorrect readings. Always check your tools before starting a project.

Continuous Learning

Stay updated with the latest welding techniques. Attend workshops and training sessions. They offer valuable insights into new methods. This continuous learning helps improve your skills. Better skills lead to more accurate welding thickness calculations.

Reading industry publications can also help. They provide updates on new tools and techniques. This knowledge keeps you at the forefront of welding practices. Always strive to learn more and improve your expertise.

Frequently Asked Questions

How To Calculate The Thickness Of Welding?

Calculate welding thickness by considering the material type, joint design, and welding process. Consult relevant welding codes or standards.

What Is The Formula For Welding Calculation?

The formula for welding calculation is: Heat Input = (Voltage x Current x 60) / (Travel Speed x 1000). This helps determine welding parameters.

What Is The Rule Of Thumb For Weld Thickness?

The rule of thumb for weld thickness is to match the weld size to the thickness of the thinnest material being joined. For optimal strength, ensure weld thickness is equal to or slightly less than the thinnest part’s thickness.

What Determines Weld Thickness?

Weld thickness is determined by material type, joint design, welding process, and load requirements. Skilled welders and engineers assess these factors for optimal weld thickness.

Conclusion

Calculating welding thickness is essential for strong, safe joints. Follow the steps outlined for accurate results. Practice makes perfect, so keep refining your technique. Proper tools and methods ensure success. Remember, every weld is different. Adjust your approach as needed.

Always prioritize safety and quality. With time, your skills will improve. Happy welding!