Welding is a practical skill for many projects, big or small. Finding the cheapest metal for welding can save you money without sacrificing quality.

Many types of metals are suitable for welding. Some are more affordable than others. Understanding which metals are budget-friendly can help you make smart choices. Not all metals are equal in cost or performance. Some are easier to weld, while others are more durable.

This guide will explore the most cost-effective metals for welding. You will learn about their benefits, uses, and why they are cheaper. By the end, you will be better equipped to choose the right metal for your welding needs. Save money and get the job done right.

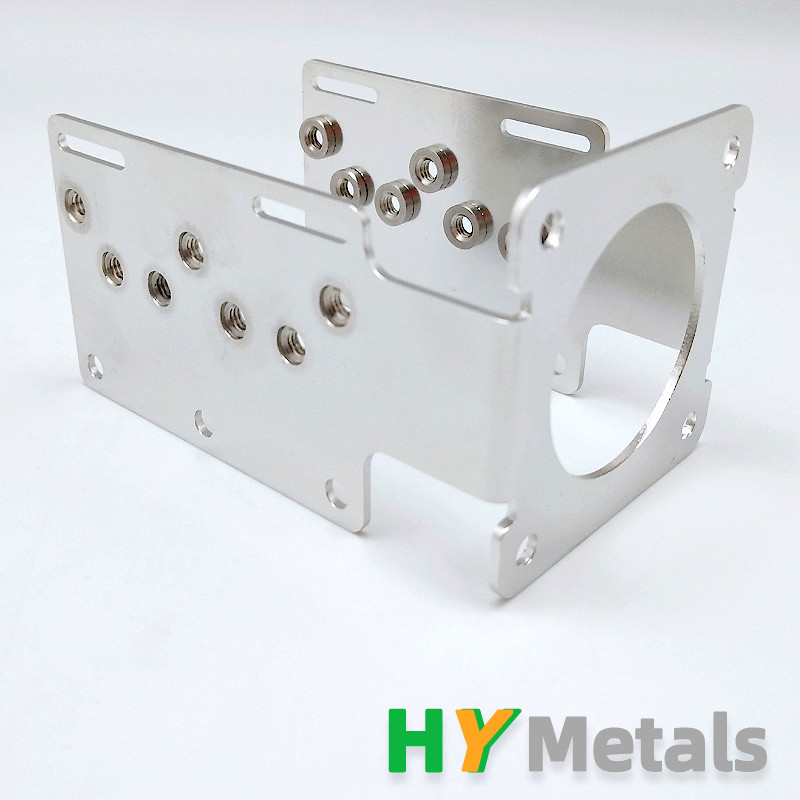

Credit: www.hymetalproducts.com

Introduction To Budget-friendly Welding

Welding can be an expensive hobby or profession, but it doesn’t always have to break the bank. If you’re looking to get started without emptying your wallet, you’re in the right place. Knowing which metals are the most cost-effective can save you a lot of money, especially when you’re just starting out. So, let’s dive into the world of budget-friendly welding!

Importance Of Cost-effective Welding

Why should you care about the cost of metals? Well, if you’re welding for fun or as a job, keeping costs down is crucial. Saving money on materials means you can spend more on tools, learning, or even other hobbies. Plus, it allows more room for mistakes and learning, which is especially important for beginners. After all, practice makes perfect, right?

Factors Affecting Metal Costs

Several factors influence the cost of welding metals. Here are a few key ones to keep in mind:

- Availability: Common metals like mild steel are cheaper because they are readily available. Rare metals are often more expensive.

- Purity: Pure metals can be more costly. Alloys, which are a mix of metals, are usually cheaper.

- Market Demand: Metals in high demand, like aluminum, might be pricier due to their popularity.

- Processing Costs: How much it costs to process and prepare the metal also affects its price. Simpler processes often mean lower costs.

Understanding these factors can help you make smarter choices and save money.

| Metal | Cost | Best Use |

|---|---|---|

| Mild Steel | Low | General welding projects |

| Aluminum | Medium | Lightweight projects |

| Stainless Steel | High | Corrosion-resistant projects |

Mild Steel

Mild steel is a popular choice for welding due to its low cost and versatility. It is easy to work with and can be used in many applications. Its properties make it an excellent option for beginners and professionals alike.

Properties Of Mild Steel

Mild steel, also known as low carbon steel, contains a small amount of carbon. This makes it easier to weld and shape. It is strong and durable, making it ideal for many projects. Mild steel also resists rust when coated properly.

Why Mild Steel Is Affordable

Mild steel is less expensive because it has a simple production process. It requires fewer alloying elements, which keeps costs down. It is widely available, so prices remain competitive. This makes it a budget-friendly option for welding projects.

Common Uses In Welding

Many industries use mild steel for welding. It is common in construction for building structures and frameworks. It is also used in automotive manufacturing for parts and repairs. DIY enthusiasts use mild steel for home projects and repairs. Its versatility makes it a go-to choice for many welders.

Aluminum

Aluminum is a popular choice for welding projects due to its affordability and unique properties. It is a lightweight metal known for its corrosion resistance and versatility. Many welders prefer aluminum for its ease of use and cost-effectiveness.

Benefits Of Aluminum

Aluminum is lightweight, making it easy to handle during welding. It has excellent corrosion resistance, which ensures longevity in various environments. This metal is also highly conductive, aiding in efficient heat transfer. Additionally, aluminum is abundant and recyclable, contributing to its affordability and sustainability.

Cost Comparison With Other Metals

Aluminum is generally cheaper than metals like stainless steel and titanium. Its lower cost makes it an attractive option for budget-conscious projects. While copper is also popular, it is more expensive than aluminum. This price difference makes aluminum a preferred choice for many welders.

Popular Aluminum Welding Projects

Many projects use aluminum due to its versatility and affordability. Common applications include automotive parts, such as frames and panels. Aluminum is also used in constructing boats and marine equipment. Home improvement projects like outdoor furniture and fencing often feature aluminum. Its lightweight nature makes it ideal for portable structures and devices.

Stainless Steel

When it comes to welding, choosing the right metal can make a big difference in both cost and quality. One of the most popular metals for welding is stainless steel. Why? Because it’s strong, durable, and versatile. But is it the cheapest option? Let’s dive into the world of stainless steel and find out more.

Advantages Of Stainless Steel

Stainless steel is a top choice for many welders. Here are some reasons why:

- Corrosion Resistance: Stainless steel does not rust easily. This makes it perfect for projects that need to withstand water or harsh environments.

- Strength: It’s incredibly strong. This means that structures made from stainless steel are durable and long-lasting.

- Versatility: You can use stainless steel for a wide range of projects, from kitchen appliances to industrial equipment.

Budget Considerations

Now, let’s talk about the cost. Stainless steel is not the cheapest metal for welding. However, it offers great value for the money. Here’s why:

- Long-term Savings: Because it lasts longer, you won’t need to replace it as often. This saves money in the long run.

- Low Maintenance: It requires less upkeep. You don’t have to worry about rust and frequent repairs.

But, if you’re on a tight budget, you might want to consider other metals like mild steel. It’s cheaper upfront, but it doesn’t have the same benefits as stainless steel.

Applications In Welding

So, where can you use stainless steel in welding? The possibilities are endless:

- Kitchen Appliances: Think about your refrigerator or dishwasher. Many of these are made from stainless steel.

- Medical Equipment: Stainless steel is also used in hospitals. It’s safe and easy to clean.

- Construction: From buildings to bridges, stainless steel is a go-to material for construction projects.

- Automotive Industry: Many car parts are made from stainless steel because of its strength and resistance to corrosion.

In short, stainless steel is a fantastic option for welding. It might not be the cheapest, but its advantages often outweigh the initial cost. So, next time you have a welding project, consider using stainless steel. You won’t be disappointed!

Galvanized Steel

Galvanized steel offers an affordable option for welding projects. Its zinc coating resists rust, making it durable and cost-effective. Ideal for beginners and professionals alike.

Galvanized steel is a popular choice for welding projects. It is both affordable and widely available. Its unique coating prevents rust and corrosion, making it durable.Characteristics Of Galvanized Steel

Galvanized steel has a zinc coating. This coating protects the steel from rust. It extends the lifespan of the steel. The steel remains strong and durable. The zinc coating is thin but effective. It bonds well to the steel surface.Affordability And Availability

Galvanized steel is cost-effective. It is cheaper than many other metals. It is widely available in most markets. This makes it a convenient choice. You can find it in local hardware stores. It is also available online.Usage In Welding Projects

Galvanized steel is used in various welding projects. It is ideal for outdoor structures. It resists weather and moisture. Common uses include fences, gates, and roofing. Welders prefer it for its durability. It is easy to work with and weld. Always ensure proper ventilation while welding. This prevents exposure to harmful fumes. “`

Credit: m.youtube.com

Cast Iron

Cast iron is a popular choice for welding projects due to its low cost and durability. It is a versatile material used in many industries. Despite being brittle, cast iron can be welded successfully with the right techniques and tools.

Features Of Cast Iron

Cast iron is known for its high carbon content. This gives it a hard and brittle nature. It has excellent wear resistance and can withstand high temperatures. Cast iron also has good machinability, making it easier to shape and mold.

Economic Benefits

One of the main benefits of cast iron is its affordability. It is cheaper than many other metals used in welding. This makes it a cost-effective choice for large projects. The durability of cast iron means it has a long lifespan, reducing replacement costs.

Typical Welding Applications

Cast iron is often used in automotive and machinery parts. It is also common in construction and plumbing industries. Welders use cast iron for repairing broken or cracked parts. It is ideal for creating sturdy and long-lasting structures.

Welding Rods And Electrodes

Welding is an art, and like any art form, the right tools can make all the difference. For those new to welding or working with a tight budget, finding affordable welding rods and electrodes is crucial. Let’s dive into the world of budget-friendly welding supplies to help you make informed choices without breaking the bank.

Types Of Budget-friendly Rods

When it comes to welding rods, you don’t always have to spend a fortune. Some rods are both effective and easy on your wallet. Here are a few popular options:

- 6010 Rods: Known for deep penetration, these rods are great for dirty or rusty metals. They’re versatile and often reasonably priced.

- 6011 Rods: Similar to 6010, but can be used with AC or DC currents. They are a go-to for many beginners due to their flexibility and cost-efficiency.

- 7018 Rods: These rods provide a smooth weld and are excellent for structural work. While slightly pricier, they are worth the investment for their reliability.

Cost-effective Electrodes

Choosing the right electrode can significantly impact your welding results and budget. Here are some electrodes that won’t empty your wallet:

- E6013 Electrodes: These are great for beginners and light to medium welding projects. They are easy to use and affordable.

- E7014 Electrodes: Offering a smooth arc and minimal spatter, these electrodes are excellent for high-deposition rates and are budget-friendly.

- E7024 Electrodes: Ideal for flat and horizontal positions, these electrodes are efficient and economical, making them perfect for larger projects.

Choosing The Right Supplies

Picking the right welding supplies is essential, especially when working within a budget. Here are a few tips to help you make the best choice:

- Assess Your Needs: Determine what type of welding you’ll be doing. For example, are you working on a small DIY project or a larger, structural job? Your needs will guide your choices.

- Research and Compare: Don’t just buy the first product you see. Compare different brands and prices. Online reviews can be incredibly helpful in making an informed decision.

- Quality Over Quantity: Sometimes, it’s better to spend a bit more on higher-quality rods and electrodes that will last longer and perform better.

Remember, the cheapest option isn’t always the best one. Balance cost with quality to get the best value for your money. Happy welding!

Credit: jtbmetaldesigns.wordpress.com

Tips For Cost-effective Welding

Welding can be an expensive hobby or profession, but it doesn’t have to break the bank. By employing some practical strategies, you can keep your costs low without sacrificing quality. Whether you’re a DIY enthusiast or a professional welder, these tips for cost-effective welding will help you save money and still achieve great results.

Maximizing Material Efficiency

One of the best ways to save money is to use your materials wisely. Here are a few tips to help you maximize material efficiency:

- Plan your cuts: Before you start welding, take the time to plan out your cuts and measurements. This helps minimize scrap and ensures you’re using as much of your material as possible.

- Reuse scrap: Don’t throw away your leftover pieces. Often, scrap metal can be used for smaller projects or as practice pieces.

- Accurate measurements: Measure twice, cut once. This old adage is especially true in welding, where mistakes can be costly.

Reducing Waste

Reducing waste is not only good for your wallet, but it’s also good for the environment. Here are some ways you can cut down on waste:

- Use the right amount of filler material: Too much filler material can lead to excess waste. Use just enough to get the job done properly.

- Optimize your welding settings: Adjust your welding machine settings to ensure you’re not using more gas, electricity, or consumables than necessary.

- Maintain your equipment: Regular maintenance of your welding equipment can prevent unnecessary waste and extend the life of your tools.

Finding Affordable Suppliers

Finding the right supplier can make a big difference in your welding costs. Here are some tips to help you find affordable suppliers:

- Shop around: Don’t settle for the first supplier you find. Compare prices and services from multiple suppliers to get the best deal.

- Buy in bulk: Purchasing materials in bulk can often save you money in the long run. Just make sure you have enough storage space.

- Check for discounts: Many suppliers offer discounts for repeat customers or large orders. Don’t be afraid to ask about any available deals.

By following these tips, you can keep your welding projects cost-effective without compromising on quality. Happy welding!

Frequently Asked Questions

Where To Get Scrap Metal For Practicing Welding?

You can find scrap metal for welding practice at local junkyards, metal recycling centers, or construction sites. Check online marketplaces like Craigslist or Facebook Marketplace for free or cheap metal. Ask local businesses, such as auto repair shops, for discarded metal pieces.

What Is The Easiest Metal To Weld?

Mild steel is the easiest metal to weld. It has low carbon content and offers excellent weldability, making it ideal for beginners.

What Is The Cheapest Form Of Welding?

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is the cheapest form of welding. It requires minimal equipment and is versatile.

What Is The Cheapest Way To Buy Metal?

Buy metal from local scrap yards or recycling centers for the lowest prices. Compare online deals and bulk buying discounts.

Conclusion

Choosing the cheapest metal for welding can save costs. Metals like mild steel offer affordability and ease of use. It’s important to balance cost with quality. Each project may need different metals. Research and planning help make the best choice.

Remember, safety and proper technique are key. Consider your budget and the specific needs of your project. Happy welding!