Welding aluminum can be tricky, even for experienced welders. The right tools and techniques make a big difference.

Aluminum is a popular metal in many industries due to its lightweight and corrosion-resistant properties. But welding it requires special care and equipment. Mistakes can lead to weak joints or damaged material. This blog post will guide you through the best tools and methods for welding aluminum.

Whether you’re a beginner or a seasoned welder, understanding the right approach is key. We’ll explore different welding processes, essential equipment, and practical tips to ensure strong, clean welds. Get ready to improve your aluminum welding skills and achieve professional results.

Credit: taberextrusions.com

Introduction To Aluminum Welding

Welding aluminum can seem like a daunting task, especially if you’re new to it. However, with the right knowledge and tools, you can master it in no time. Aluminum is a fantastic material – it’s lightweight, strong, and resistant to corrosion. Whether you’re working on a small DIY project or a large industrial job, understanding the basics of aluminum welding is crucial to your success.

Importance Of Choosing The Right Method

Choosing the correct welding method is essential when working with aluminum. Why, you ask? Because aluminum behaves differently than other metals. It has a lower melting point and a higher thermal conductivity. This means it heats up quickly and can easily warp or burn through if not handled properly.

- TIG Welding (GTAW): Great for thin materials and offers precise control.

- MIG Welding (GMAW): Faster and better for thicker materials.

- Stick Welding (SMAW): Less common but still useful in some scenarios.

Each method has its own set of advantages and disadvantages. For example, TIG welding is ideal for thin aluminum sheets, while MIG welding is faster and more suitable for thicker pieces. It’s all about picking the right tool for the job.

Challenges In Welding Aluminum

Welding aluminum isn’t without its challenges. Here are some common hurdles you might face:

- Oxidation: Aluminum quickly forms an oxide layer that can interfere with welding. Cleaning the surface before welding is crucial.

- Porosity: If not properly shielded, aluminum welds can develop tiny holes or pores. This weakens the weld.

- Heat Control: Aluminum’s high thermal conductivity means it can easily overheat. Controlling the heat is key to a good weld.

But don’t let these challenges scare you off. With practice and the right equipment, you’ll be welding aluminum like a pro. Remember, every expert was once a beginner. So, put on your welding helmet and give it a try!

Mig Welding For Aluminum

MIG welding is a popular method for joining aluminum. It is known for its efficiency and precision. This process uses a wire electrode and a shielding gas. The gas protects the weld area from contamination. Many welders prefer MIG welding for aluminum due to its benefits.

Advantages Of Mig Welding

MIG welding offers several advantages. It provides a cleaner weld with less spatter. This results in a smoother finish. The process is faster compared to other methods. It saves time and increases productivity. MIG welding also allows for better control. This is especially important for thin aluminum sheets. The process is user-friendly. Even beginners can achieve good results with practice.

Best Practices For Mig Welding

Proper preparation is crucial for successful MIG welding. Clean the aluminum surface thoroughly. Remove any dirt, grease, or oxide layer. Use a stainless steel brush for this purpose. Select the right filler material. Choose a wire that matches the base metal. Adjust the welder settings correctly. Set the voltage and wire feed speed according to the material thickness. Use a steady hand and maintain a consistent speed. This ensures a strong and even weld.

Shielding gas selection is important. Argon is the preferred choice for aluminum. It provides the best results. Ensure proper ventilation in the workspace. This is crucial for safety. Wear appropriate protective gear. Gloves, helmet, and protective clothing are essential. Practice makes perfect. Keep refining your technique for better outcomes.

Tig Welding For Aluminum

When it comes to welding aluminum, TIG welding stands out as a top choice for many professionals and hobbyists alike. This method, also known as Gas Tungsten Arc Welding (GTAW), offers precision and control that is unmatched by other welding techniques. But what makes TIG welding so special for aluminum? Let’s dive into the benefits and techniques that make it the go-to method for many.

Benefits Of Tig Welding

TIG welding brings several advantages to the table, especially when working with aluminum. Here are some key benefits:

- Precision: TIG welding provides a high level of control, which is crucial for delicate aluminum work.

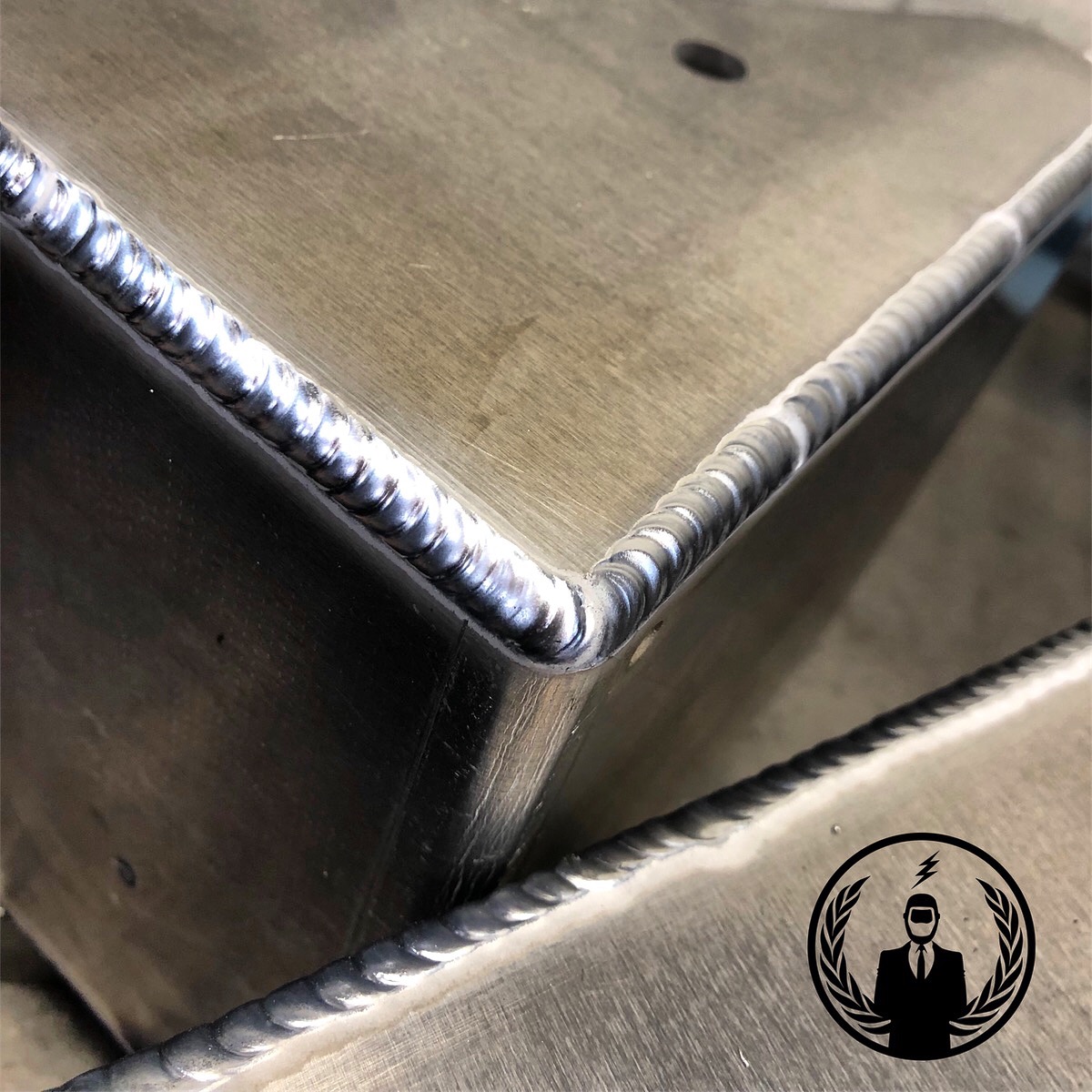

- Clean Welds: This method produces clean and aesthetically pleasing welds, reducing the need for post-weld cleanup.

- Versatility: TIG welding is suitable for a variety of metals, but it excels with aluminum due to its ability to handle thin materials.

- Heat Control: The process allows for precise heat input, which is essential for preventing warping in aluminum.

Techniques For Tig Welding

Mastering TIG welding requires practice and an understanding of specific techniques. Here are some tips to help you get started:

- Clean the Aluminum: Aluminum must be free of any contaminants. Use a stainless steel brush dedicated to aluminum to clean the surface before welding.

- Use the Right Tungsten: For aluminum, use a pure tungsten or a zirconium tungsten electrode. This ensures a stable arc.

- Set the Correct Amperage: Adjust the amperage based on the thickness of the aluminum. Too high, and you risk burning through; too low, and you won’t achieve a proper weld.

- Practice Your Technique: Focus on maintaining a steady hand and consistent speed. A foot pedal can help control the heat input more precisely.

So, there you have it! With the right approach and a bit of practice, TIG welding can become your best ally in creating strong and beautiful aluminum welds. Remember, even the pros started as beginners, so don’t get discouraged if it takes a little time to perfect your technique. Happy welding!

Credit: www.gabrian.com

Stick Welding For Aluminum

When it comes to welding aluminum, stick welding (also known as Shielded Metal Arc Welding or SMAW) is often overlooked. But it can be a handy method in certain situations. Stick welding is straightforward and versatile. It’s perfect for those who want a simple approach without too much fuss. Let’s dive into when to use stick welding for aluminum and some tips to do it effectively.

When To Use Stick Welding

Stick welding for aluminum isn’t always the first choice, but it shines in specific scenarios. Here’s when you might want to consider it:

- Outdoor Jobs: If you’re working outside, stick welding is less sensitive to wind than other methods.

- Thicker Materials: It’s ideal for thicker aluminum pieces. Thin aluminum can be tricky with stick welding.

- Cost-Effective: Stick welding equipment is generally cheaper and more portable. No need for expensive gas or complex setups.

In short, if you need a rugged, no-frills welding method, stick welding might be just what you need.

Tips For Effective Stick Welding

Want to make sure your stick welding goes smoothly? Here are some tips:

- Use the Right Electrode: Choose an electrode designed for aluminum. This makes a big difference in the quality of your weld.

- Clean the Aluminum: Aluminum can have a thin oxide layer. Clean it off with a brush to get better results.

- Control the Heat: Aluminum heats up quickly. Use short welding runs to avoid overheating.

- Practice Your Technique: Stick welding requires a steady hand. Practice on some scrap metal before tackling your main project.

Remember, stick welding aluminum can be challenging, but with these tips, you’ll be well on your way to mastering it.

In conclusion, while stick welding might not be the go-to for every aluminum welding job, it has its place. With the right approach and a bit of practice, you can achieve great results. Happy welding!

Tools For Aluminum Welding

Aluminum welding can be tricky, but with the right tools, it’s like a walk in the park. Whether you’re a seasoned pro or just starting out, having the right equipment is crucial. Let’s dive into the essential tools you’ll need and some top brands to consider for your aluminum welding projects.

Essential Welding Equipment

First things first, let’s talk about the must-have tools for aluminum welding:

- MIG Welder: A good MIG welder is like a trusty sidekick. It’s perfect for welding aluminum because it offers control and precision.

- TIG Welder: If you’re aiming for clean, beautiful welds, a TIG welder is your go-to. It provides excellent control over the welding process.

- Spool Gun: This handy tool helps feed the aluminum wire smoothly, reducing tangles and ensuring a steady flow.

- Welding Helmet: Safety first! A reliable welding helmet will protect your eyes and face from sparks and intense light.

- Protective Gear: Don’t forget gloves, a welding jacket, and safety glasses. You want to stay safe while creating those beautiful welds.

Recommended Brands And Models

When it comes to choosing the right equipment, it’s all about quality and reliability. Here are some top brands and models that stand out:

- Miller Electric: Known for their durability and performance, Miller’s Millermatic 211 is a favorite among welders.

- Lincoln Electric: The Power MIG 210 MP is a versatile machine that’s perfect for both beginners and experienced welders.

- Hobart: For those on a budget, the Handler 140 offers great value without compromising on quality.

- ESAB: The Rebel EMP 215ic is a powerful and portable option, making it ideal for various welding projects.

Choosing the right tools can make all the difference in your welding projects. It’s not just about having the best brands; it’s about finding what works best for you. So, gear up, stay safe, and happy welding!

Safety Precautions

Welding aluminum can be tricky, but it’s also very rewarding. However, safety must always come first. Whether you’re a seasoned welder or a beginner, understanding and following safety precautions is crucial. Let’s dive into some key safety measures to keep you safe and sound while you work with aluminum.

Protective Gear

Wearing the right protective gear is a must. Here’s what you need:

- Welding Helmet: Protects your eyes and face from harmful sparks and UV rays. Choose one with an auto-darkening feature for better visibility.

- Gloves: Use thick, heat-resistant gloves to shield your hands from burns.

- Long-sleeved Clothing: Wear flame-resistant shirts and pants to guard your skin against sparks and hot metal.

- Boots: Steel-toed boots offer protection if you accidentally drop heavy tools or metal pieces.

- Ear Protection: Welding can be loud, so earplugs or earmuffs help protect your hearing.

Safe Work Practices

Practicing safe work habits can prevent accidents. Consider these tips:

- Work in a Ventilated Area: Aluminum welding produces fumes. Ensure good ventilation to avoid inhaling toxic gases. </li

- Clean Your Workspace: Remove any flammable materials from your work area to prevent fires.

- Check Your Equipment: Inspect your welding tools and equipment regularly to ensure they’re in good working condition.

- Stay Focused: Concentrate on your work. Distractions can lead to mistakes and injuries.

- Know Emergency Procedures: Be aware of how to use fire extinguishers and first aid kits in case of an emergency.

By following these simple safety precautions, you can make your welding experience safer and more enjoyable. Remember, safety is not just a priority; it’s a habit. So, gear up, stay alert, and weld on!

Common Mistakes

Welding aluminum can be tricky. There are common mistakes that even seasoned welders make. These errors can affect the quality of your welds, leading to wasted materials and time. Let’s dive into some of these common mistakes and how to avoid them.

Avoiding Warping

Warping is a common problem when welding aluminum. Aluminum is more prone to warping due to its high thermal conductivity and low melting point. To avoid warping, follow these tips:

- Use Clamps: Clamps can help hold the pieces in place and reduce movement during welding.

- Control Heat: Applying too much heat can cause the aluminum to warp. Use a lower heat setting and take breaks to let the material cool.

- Preheat the Material: Preheating aluminum can reduce the temperature difference during welding, preventing warping.

- Weld in Small Sections: Instead of welding the entire joint at once, weld in small sections to control the heat.

Preventing Cracks

Cracks in aluminum welds are frustrating and can compromise the strength of the joint. To prevent cracks, consider the following:

- Clean the Surface: Dirty surfaces can lead to weak welds. Clean the aluminum thoroughly before welding.

- Use the Right Filler Material: Using the wrong filler material can cause cracks. Make sure to use a filler that matches the base metal.

- Control the Welding Speed: Welding too fast or too slow can cause cracks. Find a steady, moderate speed for the best results.

- Post-Weld Heat Treatment: Applying a post-weld heat treatment can relieve stresses and prevent cracks.

Remember, practice makes perfect. Don’t be afraid to make mistakes and learn from them. Every welder, no matter how experienced, has had their fair share of warping and cracks. With time and patience, you’ll improve your skills and create strong, reliable welds.

Have you ever struggled with warping or cracks in your aluminum welds? Share your experiences in the comments below!

Credit: www.westermans.com

Frequently Asked Questions

What Type Of Welding Is Best For Aluminum?

TIG welding is best for aluminum due to its precision and control. MIG welding also works well for thicker aluminum.

Is Mig Or Tig Better For Welding Aluminum?

TIG welding is better for aluminum. It provides precise control and cleaner welds. MIG welding is faster but less precise. Choose TIG for high-quality and detailed aluminum projects.

What Is The Best Tool For Welding Aluminum?

The best tool for welding aluminum is a TIG (Tungsten Inert Gas) welder. It offers precision and clean welds.

How Good Is Jb Weld On Aluminum?

JB Weld works well on aluminum. It creates a strong, durable bond. Proper surface preparation ensures the best results.

Conclusion

Selecting the right equipment for welding aluminum is crucial. It ensures strong, clean welds. Always consider your project’s needs and budget. Practice and patience also play vital roles. Remember, safety first. Use protective gear and work in a well-ventilated area.

Happy welding!