Welding is an essential skill in metalworking. It joins metal pieces for various projects, big or small.

Choosing the right welding method can be challenging. There are many techniques, each with its own benefits. Some methods are perfect for beginners, while others are better for experts. Understanding these options helps in making the best choice for your project.

This blog post will explore the best welding methods for metal. We’ll break down each technique, making it easy to understand. Whether you’re new to welding or looking to refine your skills, you’ll find valuable insights here. Join us as we dive into the world of metal welding, ensuring your next project is a success.

Introduction To Metal Welding

Welding is essential in metalwork, whether you’re building a bridge or fixing a car. But what exactly is welding, and why is it so important? In this blog post, we’ll dive into the basics of metal welding. We’ll explore why strong joints matter and look at some popular welding methods. Ready to spark up your knowledge? Let’s get started!

Importance Of Strong Joints

Why should you care about strong joints in welding? Well, imagine building a house with weak bricks. It wouldn’t stand for long, right? The same goes for metal structures. Strong joints ensure that the pieces stay together, even under pressure. This is crucial for safety and durability.

Here are a few reasons why strong joints are important:

- Safety: Weak joints can cause structures to fail, leading to accidents.

- Longevity: Strong joints ensure that the structure lasts longer.

- Efficiency: Good joints mean less need for repairs and maintenance.

Popular Welding Methods

There are several methods to weld metal, each with its own benefits. Let’s take a look at some of the most popular ones:

| Method | Benefits |

|---|---|

| MIG Welding | Easy to learn and great for thin metals. |

| TIG Welding | Provides high-quality welds, perfect for detailed work. |

| Stick Welding | Works well outdoors and on rusty surfaces. |

Each method has its own quirks. For example, MIG welding is often the go-to for beginners because it’s straightforward. However, if you’re aiming for precision, TIG welding might be your best bet. And if you’re working outside, battling the elements, stick welding is your trusty companion.

So, which welding method is the best? It depends on your project and skill level. Don’t worry if it feels overwhelming; like learning to ride a bike, it gets easier with practice.

Welding is a skill that pays off, whether you’re a hobbyist or a professional. Understanding the importance of strong joints and knowing the popular methods can make a world of difference in your projects. So, grab your welding helmet and get ready to make some sparks fly!

Tig Welding

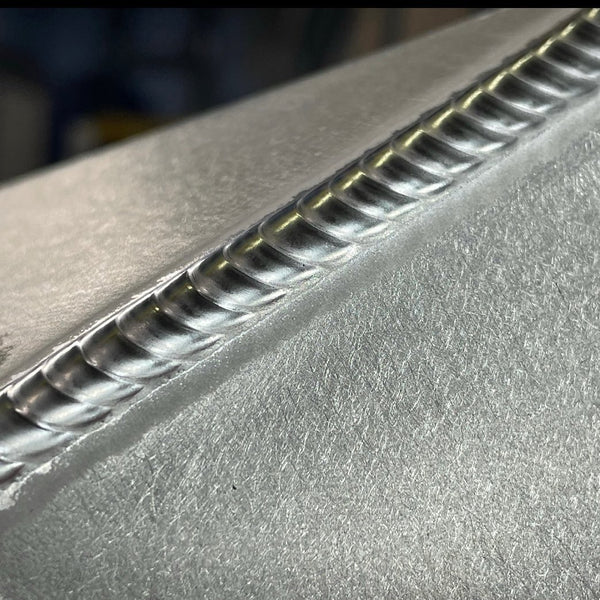

TIG welding, or Tungsten Inert Gas welding, is a precise welding method. This technique uses a non-consumable tungsten electrode. The electrode produces the weld. A shielding gas, usually argon, protects the weld area. TIG welding is known for its high-quality and clean welds.

Advantages Of Tig Welding

TIG welding offers many advantages. It provides high-quality welds. The welds are clean and strong. The process allows for better control. This control results in precise welds. Thin materials can be welded easily. There is less distortion in the metal. No sparks or spatter occur during welding.

TIG welding is versatile. It can be used on various metals. These include steel, aluminum, and copper. The process is also suitable for both small and large projects. Welders can work in different positions. They can weld vertically, horizontally, or overhead.

Applications And Uses

TIG welding has many applications. It is used in the aerospace industry. Aircraft parts require high precision. TIG welding ensures strong and clean joints. The automotive industry also uses TIG welding. Car frames and exhaust systems benefit from this technique.

The process is popular in the art and jewelry industry. Artists create intricate designs with TIG welding. The medical industry also relies on this method. Medical devices and tools require precise welds. TIG welding meets these needs.

In the manufacturing sector, TIG welding is essential. It is used for creating machinery and equipment. The construction industry also benefits. Structural welds on buildings and bridges use TIG welding. This method ensures safety and durability.

Mig Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a popular welding technique. It uses a continuous wire feed as an electrode and a shielding gas to protect the weld from contamination. This method is favored for its ease of use and efficiency.

Benefits Of Mig Welding

MIG welding offers several key benefits that make it a preferred choice. It is easy to learn, making it ideal for beginners. The process is fast, allowing for quick completion of projects. The welds produced are clean and require minimal cleanup. MIG welding is versatile and can be used on various metals, including steel, aluminum, and stainless steel.

Common Uses In Industry

MIG welding is widely used in different industries due to its adaptability. In the automotive industry, it is used for assembling car frames and parts. The construction industry uses it for building structures and bridges. In the manufacturing sector, MIG welding helps in the production of machinery and equipment. It is also used in the aerospace industry for creating durable and lightweight components.

Stick Welding

When it comes to welding, there are different techniques to choose from. One of the most common and user-friendly methods is Stick Welding. It’s also known as Shielded Metal Arc Welding (SMAW). This method is great for beginners and professionals alike. Why? It’s simple to learn and very versatile. Let’s dive into the details of Stick Welding, and explore its advantages, drawbacks, and best practices.

Pros And Cons

Before you grab your welding gear, it’s important to know the pros and cons of Stick Welding. This can help you decide if it’s the right technique for your project.

| Pros | Cons |

|---|---|

|

|

Best Practices

Stick Welding can be a breeze if you follow some best practices. Here are a few tips to make your welding experience smoother:

- Choose the Right Electrode: Different electrodes work better with different metals. For example, use E6013 for mild steel. Always check the compatibility.

- Maintain a Steady Hand: Consistent motion is key. Keep your hand steady to avoid uneven welds.

- Proper Angle: Hold the electrode at a 10-15 degree angle from vertical. This helps in better penetration and cleaner welds.

- Control Your Speed: Don’t rush. Move at a consistent pace. Too fast, and you’ll get weak welds. Too slow, and you might burn through the metal.

- Clean Your Metal: Dirt, rust, and paint can mess up your weld. Clean the surface before you start.

Stick Welding might not be perfect, but it’s a reliable and flexible method. Whether you’re working on a farm or fixing a fence, it’s a handy skill to have. So, grab your gear, follow these tips, and you’ll be making strong, clean welds in no time. Remember, practice makes perfect!

Flux-cored Arc Welding

Flux-Cored Arc Welding (FCAW) is a popular welding method. It uses a special tubular wire filled with flux. This flux protects the weld from contaminants. FCAW is versatile and efficient. It’s suitable for both indoor and outdoor welding.

Why Choose Flux-cored

FCAW offers high welding speeds. It can penetrate thick metals. The process is easy to learn. It produces strong, reliable welds. It works well in windy conditions. You don’t need a shielding gas. This makes it more portable.

Typical Applications

FCAW is used in construction. It’s great for building bridges. The method is common in shipyards. It’s also used in heavy equipment repair. Many industries prefer FCAW for its efficiency. It’s a top choice for outdoor welding projects.

Credit: americantorchtip.com

Laser Welding

Laser welding is a modern technique that uses a high-powered laser beam to join metal pieces. It’s fast, precise, and efficient. This method is perfect for creating strong and clean welds, even on thin materials. But what exactly makes laser welding so special? Let’s dive into the specifics.

Precision And Efficiency

Laser welding stands out because of its precision and efficiency. The laser beam can be controlled with great accuracy, allowing for very fine welds. This is especially useful for delicate or intricate work where traditional welding might be too clumsy.

Here are some key benefits of laser welding:

- Minimal Distortion: The heat-affected zone is small, meaning the metal doesn’t warp or distort.

- High Speed: Welding can be done very quickly, which increases production rates.

- Clean Welds: The welds are often cleaner and require less post-weld finishing.

Imagine trying to fix a broken pair of glasses with a sledgehammer. It just wouldn’t work. Laser welding, on the other hand, is like using a fine needle – it’s exact and doesn’t damage the surrounding material.

Industries That Benefit

Laser welding is used in many different industries. Here are a few that see the most benefit:

- Automotive: Cars have many small parts that need to be welded precisely. Laser welding helps make strong and reliable joints, ensuring safety and performance.

- Medical Devices: Many medical tools are small and require precise welding. Laser welding is ideal for making surgical instruments and implants.

- Electronics: The tiny components in electronics need careful handling. Laser welding can join these parts without causing damage.

In these industries, having strong, clean, and precise welds is crucial. Can you imagine a pacemaker with a faulty weld? That’s why laser welding is so important.

In conclusion, laser welding is a game-changer for many industries. Its precision and efficiency make it the best choice for high-quality welding. Whether you’re in the automotive, medical, or electronics field, laser welding can help create the perfect weld every time.

Oxy-acetylene Welding

Oxy-Acetylene welding, often called gas welding, is a versatile and traditional method of welding metal. It uses a combination of oxygen and acetylene gases to create a flame that can melt and join metals together. This technique has been around for over a century and remains popular for various applications. Let’s dive deeper into the essence of oxy-acetylene welding, its historical significance, and its place in modern welding practices.

Traditional Techniques

Oxy-Acetylene welding is one of the oldest welding methods. It dates back to the early 20th century, providing a reliable means to fuse metals before the advent of more modern techniques. The process involves mixing oxygen and acetylene in a torch to produce a flame hot enough to melt steel. The welder then applies a filler rod into the molten pool to join the metals.

Here are some key traditional techniques:

- Neutral Flame: Achieved by balancing oxygen and acetylene. Used for welding most metals.

- Carburizing Flame: More acetylene than oxygen. Good for welding high-carbon steels.

- Oxidizing Flame: More oxygen than acetylene. Typically used for brass and copper.

These flames offer the flexibility to weld various metals, making oxy-acetylene welding a valuable skill for many craftsmen. Have you ever wondered why blacksmiths favor this method? It’s because of the control and precision it offers, especially in intricate metalwork.

Modern Relevance

While oxy-acetylene welding might seem old-fashioned compared to more advanced techniques like MIG or TIG welding, it still holds significant relevance today. Why, you ask? Simple: it’s affordable, portable, and versatile.

Consider these modern applications:

- Repairs: Ideal for on-site repairs where electrical power is unavailable.

- Cutting: The oxy-acetylene torch can also be used for cutting metals, making it a dual-purpose tool.

- Brazing and Soldering: Perfect for joining dissimilar metals without melting the base materials.

Moreover, many educational institutions still teach oxy-acetylene welding as a fundamental skill. It’s often the first welding technique students learn because it provides a strong foundation. Knowing how to control the flame and manage the heat is crucial for any aspiring welder.

So, whether you’re a seasoned pro or just starting, don’t overlook the value of oxy-acetylene welding. It’s like the Swiss Army knife of welding techniques – always handy and highly effective.

Choosing The Right Welding Method

When it comes to welding, choosing the right method can feel like finding a needle in a haystack. But don’t worry. With a little guidance, you can make an informed decision that ensures strong, durable welds. Whether you’re working on a car, creating art, or fixing a fence, the right welding method makes all the difference.

Factors To Consider

Before you dive into welding, think about a few important factors. These will help you choose the best method for your project.

- Material Type: What kind of metal are you welding? Different metals need different techniques.

- Thickness: Thin metals need more precision, while thicker metals can handle more heat.

- Environment: Are you welding indoors or outdoors? Wind and weather can affect your weld.

- Equipment: Do you have the right tools? Some methods need specialized equipment.

Matching Method To Metal Type

Not all welding methods are created equal. Some are perfect for specific metals, while others are more versatile. Here’s a quick guide to help you match the method to the metal:

| Metal Type | Best Welding Method |

|---|---|

| Steel | MIG Welding (Metal Inert Gas) |

| Aluminum | TIG Welding (Tungsten Inert Gas) |

| Stainless Steel | Stick Welding (Shielded Metal Arc Welding) |

| Copper | Oxy-Acetylene Welding |

Choosing the right welding method can save you time and frustration. Imagine trying to MIG weld aluminum without knowing it’s better suited for TIG welding. It’s like trying to fit a square peg in a round hole – it just won’t work!

Remember, every project is unique. Sometimes, you might need to experiment a bit to find what works best. And that’s okay. With practice and patience, you’ll get the hang of it. Happy welding!

Safety Tips For Welding

Welding is a craft that brings together pieces of metal to create something new and strong. However, as fascinating as welding can be, it’s equally important to be aware of the safety measures to protect yourself from potential hazards. Here’s a guide on safety tips for welding, focusing on essential gear and common safety practices to ensure you weld safely and effectively.

Essential Gear

Before you start welding, make sure you have the right gear. This isn’t just about looking the part; it’s about protecting yourself from serious injuries. Here’s a list of essential gear every welder should have:

- Welding Helmet: A good welding helmet will protect your eyes and face from the bright light and sparks. Look for one with an auto-darkening feature.

- Gloves: Heavy-duty gloves are crucial. They protect your hands from heat, sparks, and sharp metal edges.

- Protective Clothing: Wear long sleeves and pants made of flame-resistant material like leather or a heavy cotton blend.

- Boots: Steel-toed boots can protect your feet from falling objects and burns. Ensure they are made of leather and cover the ankles.

- Ear Protection: Welding can be noisy. Use earplugs or earmuffs to protect your hearing.

- Respirator: Some welding jobs produce fumes that are harmful if inhaled. A respirator can filter out these toxic gases.

Common Safety Practices

Having the right gear is just the first step. Following common safety practices is equally important. Here are some rules to keep in mind:

- Work in a Well-Ventilated Area: Always ensure good ventilation to avoid inhaling harmful fumes. If you’re working indoors, consider using an exhaust hood.

- Check Your Equipment: Inspect your welding equipment regularly. Ensure there are no leaks or damages that could lead to accidents.

- Keep Flammable Materials Away: Sparks can ignite flammable materials. Clear your workspace of any such hazards before starting.

- Maintain a Clean Workspace: A cluttered workspace can lead to accidents. Keep your area tidy and organized.

- Stay Focused: Welding requires attention. Avoid distractions and never weld when tired or under the influence of alcohol.

- Have an Emergency Plan: Know where the fire extinguisher is and how to use it. Keep a first aid kit nearby.

Remember, safety is paramount when welding. By using the right gear and following safety practices, you can enjoy welding and create amazing projects without risking your health. Happy welding!

Credit: tooliom.com

Credit: americantorchtip.com

Frequently Asked Questions

What Is The Strongest Weld For Metal?

TIG welding is the strongest for metal. It provides excellent precision and strength. TIG welding is ideal for critical joints.

Is Mig Or Tig Welding Better For Steel?

MIG welding is generally better for steel. It is faster and easier to learn. TIG welding offers more precision but is slower and requires more skill. Choose MIG for efficiency and TIG for detailed work.

Should I Learn Mig Or Tig Welding?

Choose MIG welding for beginners or if you need to work quickly. Opt for TIG welding for precision and detailed projects.

Which Is Better, Arc Or Mig Welding?

MIG welding is generally better for beginners due to ease of use. Arc welding is preferred for thicker materials and outdoor projects. Your choice depends on the specific project requirements.

Conclusion

Choosing the best welding method for metal ensures strong, durable connections. Each method has its own benefits and ideal uses. Understanding the differences helps you pick the right one for your project. Whether you are a beginner or a pro, knowledge is key.

Invest time in learning techniques and safety practices. This will lead to better results and safer work. Happy welding!