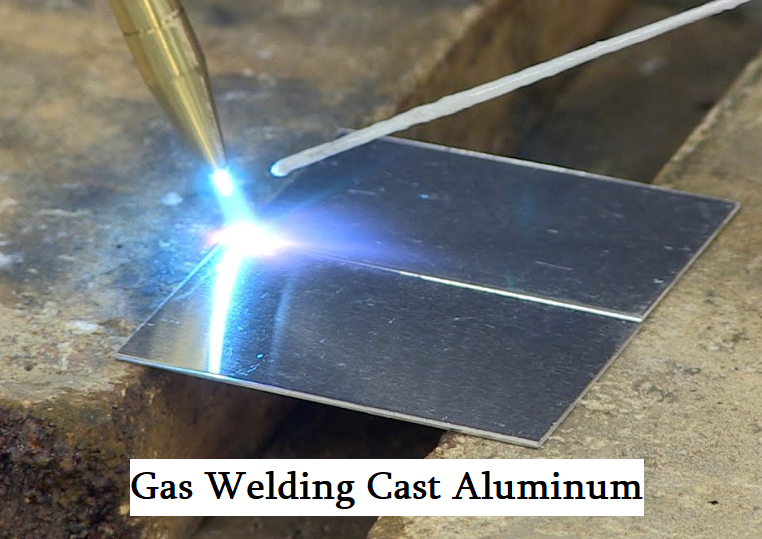

Yes, you can weld cast aluminum. But it requires special techniques and knowledge.

It’s not as easy as welding other metals. Welding cast aluminum can be tricky due to its unique properties. This metal is lightweight, strong, and resists corrosion. However, it has a lower melting point and tends to crack. These characteristics make the process challenging.

Knowing the right methods is key. In this blog post, we’ll explore the steps needed to weld cast aluminum. We will discuss the tools and techniques required for a successful weld. Whether you’re a hobbyist or a professional, this guide will help you understand the process better. Let’s dive into the world of welding cast aluminum!

Basics Of Cast Aluminum

Understanding the basics of cast aluminum is essential for welding projects. This material is popular for its lightweight and durable properties. Let’s dive into its key characteristics and common uses.

Properties

Cast aluminum is known for its excellent strength-to-weight ratio. This makes it ideal for various applications. It is resistant to corrosion, which extends its lifespan. The material also has good thermal and electrical conductivity. These properties make it useful in many industries.

Cast aluminum is easy to machine. This characteristic is beneficial for creating complex shapes. Its ability to withstand high temperatures is another advantage. This makes it suitable for automotive and aerospace applications. Despite its many benefits, cast aluminum can be challenging to weld. The presence of impurities in the material can complicate the welding process.

Common Uses

Cast aluminum is prevalent in the automotive industry. It is used in engine blocks, cylinder heads, and transmission cases. Its lightweight nature helps improve fuel efficiency. In the aerospace sector, cast aluminum components are crucial. They help reduce the overall weight of aircraft.

Household items also use cast aluminum. Items like cookware and outdoor furniture benefit from its durability. The electronics industry uses it for heat sinks and casings. These applications take advantage of its thermal conductivity.

In construction, cast aluminum is used for window frames and roofing materials. Its corrosion resistance is a significant benefit in these applications. Overall, cast aluminum’s versatility makes it a valuable material in many fields.

Credit: www.diecasting-mould.com

Challenges Of Welding Cast Aluminum

Welding cast aluminum presents a unique set of challenges. This material is different from other metals. It requires special techniques and tools. Understanding these challenges can help achieve better results.

Material Composition

Cast aluminum contains various alloying elements. These elements affect the welding process. Common elements include silicon, magnesium, and copper. Each element changes the metal’s properties. This makes welding more complex. Using the wrong technique can cause defects.

Porosity Issues

Porosity is a common problem in cast aluminum welding. Tiny holes form in the metal. These holes weaken the weld. They can also cause leaks in the final product. Contaminants in the metal often cause porosity. Cleaning the aluminum before welding can reduce this issue. Proper technique and equipment also help.

Preparation Steps

Welding cast aluminum can be tricky, but with the right preparation, it becomes much easier. Before you fire up your welder, there are crucial steps you need to follow. Let’s dive into the essential preparation steps to ensure a successful weld.

Cleaning The Surface

First things first, cleaning the surface is a must. Cast aluminum often has impurities like oil, grease, and dirt. These contaminants can mess up your weld. Imagine trying to paint on a dirty canvas – it just won’t work well. Use a wire brush to scrub the surface or wipe it down with a clean cloth soaked in acetone. This removes any grime and gives you a clean slate to work with.

| Tools | Usage |

|---|---|

| Wire Brush | Scrubbing off dirt and grime |

| Acetone | Cleaning oil and grease |

| Clean Cloth | Wiping the surface |

Preheating The Material

Next, preheating the material is key. Cast aluminum has a lower melting point, and welding it cold can lead to cracks. Think of it like warming up before a workout – it helps prevent injuries. Preheat the aluminum to around 300°F (150°C) using a propane torch or an oven. This reduces thermal shock and ensures a smoother weld.

- Use a propane torch for localized preheating.

- An oven can be used for more uniform heating.

- Preheat to around 300°F (150°C).

Preheating doesn’t have to be complicated. Just take your time and ensure the material is evenly heated. Ever tried baking cookies and ended up with burnt edges? Same idea here – even heat distribution is crucial.

By following these preparation steps, you’ll be well on your way to successfully welding cast aluminum. It’s all about taking the time to clean and preheat properly. So, grab your tools, prep your aluminum, and get ready to weld like a pro!

Choosing The Right Welding Method

Choosing the right welding method for cast aluminum is crucial. Each technique has its unique benefits. This section will help you understand two common methods: TIG Welding and MIG Welding. Knowing their differences will guide you in making the best choice.

Tig Welding

TIG Welding stands for Tungsten Inert Gas welding. It is ideal for cast aluminum. This method uses a non-consumable tungsten electrode. The process requires a filler material. It also uses an inert gas, usually argon, to protect the weld area. TIG welding offers great control. It produces clean and precise welds. This technique is best for thin sections of aluminum. It requires skill but delivers high-quality results.

Mig Welding

MIG Welding stands for Metal Inert Gas welding. It is another option for cast aluminum. This method uses a consumable wire electrode. An inert gas, often argon or helium, shields the weld. MIG welding is faster than TIG welding. It is easier to learn and use. This technique is suitable for thicker aluminum sections. While less precise than TIG, it is efficient for larger projects.

Selecting Filler Material

When welding cast aluminum, selecting the right filler material is crucial. The filler material affects the weld’s strength, durability, and appearance. Proper selection ensures a sound weld, reducing the risk of cracks and other issues.

Matching Alloys

Matching the alloy of the filler material with the base material is important. This ensures compatibility and reduces the risk of defects. For cast aluminum, the base metal is often alloyed with silicon, magnesium, or copper. Identifying the specific alloy composition helps in selecting the right filler material.

Common Filler Rods

Several types of filler rods are available for welding cast aluminum. ER4043 and ER5356 are the most common. ER4043 contains silicon, making it ideal for casting with high silicon content. It offers good fluidity and reduces the risk of cracking. ER5356, on the other hand, contains magnesium. It provides higher strength and is suitable for base metals alloyed with magnesium.

Another option is ER4047, which has higher silicon content than ER4043. This rod offers better fluidity and lower melting temperature. It minimizes the risk of hot cracking, making it suitable for difficult welds.

Choosing the right filler rod depends on the base alloy and the desired weld properties. Always refer to the manufacturer’s guidelines for the best match.

Credit: www.thefabricator.com

Welding Techniques

Welding cast aluminum can seem tricky if you are not familiar with the right techniques. But don’t worry! With some practice and the right approach, you can master this skill. Below, we will explore some key welding techniques that will help you achieve strong and clean welds on cast aluminum.

Controlling Heat Input

One of the most important aspects of welding cast aluminum is controlling the heat input. Aluminum conducts heat very well, which means it can quickly become too hot. This can lead to warping or even melting the material. To avoid this, you need to:

- Use a lower amperage setting: Lowering the amperage can help you control the heat better.

- Keep a steady pace: Move your welding torch at a consistent speed to avoid overheating one spot.

- Use a heat sink: Placing a heat sink near the welding area can help absorb excess heat.

By controlling the heat input, you can prevent damage to the cast aluminum and create a stronger weld.

Avoiding Cracks

Nobody likes cracks in their welds, right? Cracks can weaken the structure and lead to failure. So how can you avoid them? Here are some tips:

- Preheat the material: Preheating the cast aluminum to around 300°F (150°C) can reduce the risk of cracking.

- Clean the surface: Make sure the welding area is free of dirt, oil, and oxidation. This ensures a cleaner weld.

- Use the right filler material: Choose a filler material that matches the composition of the cast aluminum.

I remember the first time I tried welding cast aluminum without preheating. It was a disaster! The weld cracked almost immediately. After some research and practice, I learned the importance of preheating and haven’t had issues since.

By following these steps, you can avoid cracks and produce a much more reliable weld.

In conclusion, welding cast aluminum requires some special techniques, but it is definitely achievable. By controlling the heat input and avoiding cracks, you can create strong and beautiful welds. So, grab your welding torch and give it a try. You might surprise yourself with what you can achieve!

Post-welding Procedures

Alright, so you’ve just welded cast aluminum. Great job! But hang on, the process isn’t over yet. There are a few more steps to follow to make sure your weld is strong and reliable. Let’s dive into the post-welding procedures. These steps are crucial to ensure your weld stands the test of time.

Cooling Process

First things first, the cooling process. It might be tempting to rush this part, but patience is key. Cast aluminum should cool slowly to avoid any unwanted stress or cracking. Just like how you wouldn’t want to shock a hot glass with cold water, you don’t want to rapidly cool your weld.

Here’s a simple trick: cover the welded part with a heat blanket. This helps it cool down gradually. If you don’t have a heat blanket, no worries! You can use dry sand or even a thick cloth. The goal is to keep the temperature drop slow and steady.

Inspection And Testing

Now, onto inspection and testing. This step is like the cherry on top. You want to make sure your weld is perfect and there are no hidden flaws. Start with a visual inspection. Look for any cracks, holes, or irregularities.

Feeling confident? Great! Let’s move on to some testing. A simple but effective method is the dye penetrant test. Here’s how you do it:

- Clean the weld area thoroughly.

- Apply the penetrant (a special dye).

- Wait for the penetrant to soak in.

- Wipe off the excess dye.

- Apply the developer (this makes cracks visible).

Pretty cool, right? It’s like being a detective, finding those sneaky cracks. If you spot any issues, don’t worry. Just go back and fix them. Better safe than sorry!

Credit: www.youtube.com

Expert Tips For Success

Welding cast aluminum can be challenging. But with the right approach, you can achieve great results. Here are expert tips to help you succeed.

Practice And Patience

Start with small projects. Practice makes perfect. Take your time to learn the technique. Don’t rush the process. You’ll improve with each attempt. Understand that mistakes will happen. Learn from them. Patience is key to mastering welding. Build your confidence gradually. Experiment with different methods. Find what works best for you.

Safety Precautions

Always prioritize safety. Wear protective gear. Use gloves, goggles, and a welding helmet. Ensure your workspace is well-ventilated. Aluminum fumes can be harmful. Keep a fire extinguisher nearby. Be prepared for any accidents. Avoid welding near flammable materials. Keep your area clean and organized. Double-check your equipment. Make sure it’s in good condition. Faulty tools can cause accidents.

Frequently Asked Questions

What Is The Best Way To Weld Cast Aluminum?

To weld cast aluminum, clean the surface thoroughly. Use a TIG or MIG welder with proper aluminum filler rods. Preheat the metal to reduce cracking.

Can You Fix Broken Cast Aluminum?

Yes, you can fix broken cast aluminum. Use welding or brazing techniques for the best results. Ensure proper cleaning and preparation before repair.

Will Jb Weld Hold Cast Aluminum Together?

Yes, JB Weld can bond cast aluminum effectively. It’s strong, durable, and resistant to extreme temperatures. Proper surface preparation is essential for the best results.

Can I Weld Cast Aluminum With A Mig Welder?

Yes, you can weld cast aluminum with a MIG welder. Use a spool gun for better control. Ensure the aluminum is clean and preheated.

Conclusion

Welding cast aluminum is possible with the right techniques. Preparation is key. Clean the surface and remove impurities. Use appropriate welding equipment and filler materials. Practice makes perfect. Small projects help you gain confidence. Remember, patience and precision lead to better results.

With time, welding cast aluminum becomes easier. You can achieve strong, durable welds. Happy welding!