Yes, you can weld galvanized steel, but it requires special precautions. Galvanized steel has a zinc coating that can cause issues if not handled correctly.

Welding galvanized steel is different from welding regular steel. The zinc coating produces toxic fumes when heated. This can be harmful if inhaled. Proper ventilation and safety measures are crucial. Additionally, the zinc can cause weld defects if not removed or managed.

Understanding the right techniques ensures a safe and strong weld. This article will guide you through the necessary steps and precautions for welding galvanized steel. It’s important to follow these guidelines to protect yourself and achieve good results. Let’s explore what you need to know about this process.

Introduction To Welding Galvanized Steel

Have you ever wondered if you can weld galvanized steel? It’s a question many DIY enthusiasts and professionals ask. Welding galvanized steel involves some unique challenges. But, don’t worry, we’ll break it down for you in simple terms. Let’s dive into the world of galvanized steel and see why welding it is both essential and common in many industries.

Importance Of Welding Galvanized Steel

Why is welding galvanized steel important? Well, galvanized steel is steel coated with a layer of zinc. This coating helps protect the steel from rust and corrosion. It makes the steel more durable and longer-lasting. When you need to weld it, the zinc coating can pose some issues. But, knowing the right techniques can make a big difference.

Welding galvanized steel ensures that structures made from this material remain strong and reliable. Whether you are working on a large construction project or a small DIY job at home, welding galvanized steel can help ensure that your work stands the test of time.

Common Applications

Welding galvanized steel is common in various applications. Let’s take a look at where you might see it used:

- Construction: Many building frames and supports use galvanized steel because of its strength and resistance to rust.

- Automotive Industry: Car bodies and parts often use galvanized steel to prevent rust and extend the life of the vehicle.

- Outdoor Structures: Items like fences, playground equipment, and street signs are often made from galvanized steel to withstand the elements.

- Household Items: Things like water tanks, buckets, and even some furniture can be made from galvanized steel for added durability.

These are just a few examples. The versatility and strength of galvanized steel make it a popular choice in many fields.

Challenges In Welding Galvanized Steel

Welding galvanized steel presents many challenges. The zinc coating and health risks make the task difficult. Understanding these issues is crucial for a successful weld.

Zinc Coating Issues

The zinc coating on galvanized steel causes problems. The coating melts at a lower temperature than the steel. This can lead to poor weld quality. Zinc also produces a thick, white smoke when heated. This smoke can affect visibility and weld penetration. Removing the zinc coating before welding can help, but it adds extra work.

Health And Safety Risks

Welding galvanized steel poses health risks. The zinc fumes released can be harmful. Inhaling these fumes can cause metal fume fever. Symptoms include chills, fever, and nausea. Proper ventilation is essential to avoid these risks. Wearing a respirator can also protect from harmful fumes.

Essential Safety Precautions

Welding galvanized steel can be quite a task, especially if you’re not familiar with the specific safety precautions required. But don’t worry! In this section, we’ll cover the Essential Safety Precautions you need to take when welding galvanized steel. By following these guidelines, you’ll be able to work safely and effectively. Let’s dive in!

Protective Gear

When welding galvanized steel, wearing the right protective gear is crucial. Here’s a quick rundown of what you need:

- Welding Helmet: A good quality welding helmet will protect your eyes from the bright light and harmful UV rays.

- Respirator Mask: Galvanized steel releases zinc fumes when welded. These fumes can be harmful if inhaled, so a respirator mask is a must.

- Gloves: Heat-resistant welding gloves will protect your hands from burns and sparks.

- Protective Clothing: Wear a long-sleeved shirt and pants made of fire-resistant material to protect your skin.

Think of it this way: would you go into a battle without armor? Of course not! So, suit up properly before you start welding.

Ventilation Requirements

Ventilation is another critical factor when welding galvanized steel. The zinc fumes released during the welding process can be toxic. Here’s what you need to do:

- Work in a Well-Ventilated Area: Ensure your workspace has good airflow. If possible, weld outdoors or in a space with plenty of windows and fans.

- Use Exhaust Systems: If you’re working indoors, use an exhaust system or a fume extractor to remove harmful fumes from the air.

- Take Breaks: Don’t weld continuously for long periods. Take breaks to step outside and breathe fresh air.

Remember, your lungs are precious. Treat them well by ensuring proper ventilation while you work.

Now, let me share a little story. I remember my first time welding galvanized steel; I was so focused on the task that I forgot to turn on the fan. After just a few minutes, I felt dizzy and had to stop. Since then, I’ve never underestimated the importance of ventilation. Trust me, it’s not worth the risk!

By following these Essential Safety Precautions, you’ll be well on your way to welding galvanized steel safely and effectively. Stay safe and happy welding!

Credit: crossroadsgalvanizing.com

Preparing Galvanized Steel For Welding

Welding galvanized steel isn’t a walk in the park. If you just dive in without any preparation, you’re asking for trouble. The zinc coating on the steel can lead to poor weld quality and even health hazards. But don’t worry, I’ve got you covered. Let’s break down the process of getting your galvanized steel ready for welding.

Surface Cleaning Techniques

The first step in preparing galvanized steel for welding is cleaning the surface. You want to remove any dirt, oil, or other contaminants that can mess up your weld. Here are a few techniques you can use:

- Degreasing: Use a degreaser to remove oil and grease. It’s like giving the steel a good bath.

- Wire Brushing: A wire brush can help scrub off any loose dirt or debris. Think of it as brushing your teeth, but for steel.

- Solvent Cleaning: Solvents can be effective in removing stubborn contaminants. Just make sure to use a solvent that is safe for your particular type of steel.

Remember, a clean surface is crucial for a strong weld. Don’t skip this step!

Removing Zinc Coating

The next hurdle is dealing with the zinc coating. Welding directly on the zinc can cause problems like porosity and cracking. Plus, it releases toxic fumes. So, here’s how you can get rid of that coating:

- Grinding: Use a grinder to remove the zinc coating. Be careful not to grind too much and weaken the steel.

- Chemical Strippers: These can effectively strip away the zinc. Just follow the instructions and wear protective gear.

- Mechanical Abrasion: Sandblasting or using a flap disc can also do the trick. It’s like giving the steel a rough exfoliation.

Once the zinc coating is removed, you’re ready to weld. But always work in a well-ventilated area and wear proper safety gear to protect yourself from fumes and debris.

Welding galvanized steel may seem daunting, but with the right preparation, you can achieve a strong, clean weld. So roll up your sleeves and get to work!

Welding Techniques For Galvanized Steel

Welding galvanized steel is possible but requires special techniques. Removing the zinc coating from the welding area is crucial. Use proper ventilation to avoid harmful fumes.

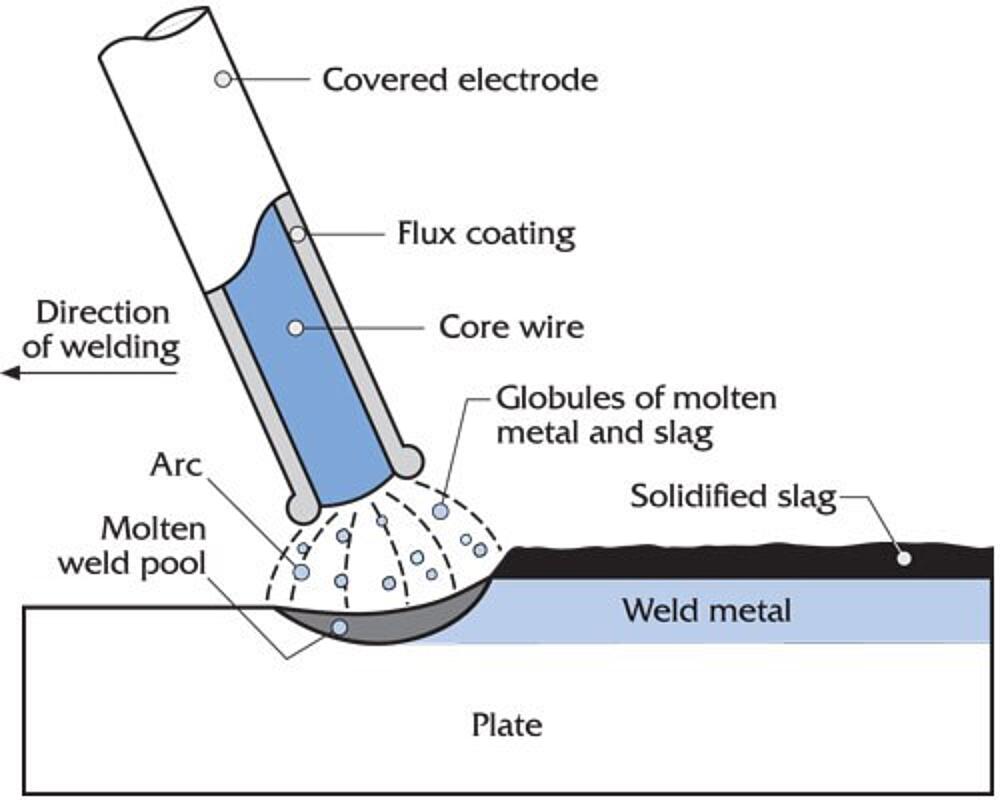

Welding galvanized steel can be challenging. The zinc coating produces toxic fumes. Proper techniques and safety measures are crucial. Learn about different welding methods to achieve success.Mig Welding

MIG welding is popular for galvanized steel. This method uses a wire electrode. It’s fed through a welding gun. The process is semi-automatic. MIG welding is fast and efficient. Before starting, remove the zinc coating. Use a grinder or chemical solution. This prevents toxic fumes. It also improves weld quality. Ensure proper ventilation for safety. Set the welder to the right settings. Use a shielding gas like argon. Adjust the voltage and wire speed. Practice on scrap metal first. This helps fine-tune the settings. MIG welding creates strong welds. It’s suitable for various projects. From small repairs to large constructions.Tig Welding

TIG welding offers precision. It uses a tungsten electrode. The process is manual. Control is achieved using a foot pedal. TIG welding is slower than MIG. But it provides cleaner results. Remove the zinc coating before welding. This avoids contamination. It also reduces fume production. Use a grinder or chemical stripper. Set up the TIG welder correctly. Choose a suitable filler rod. Use a shielding gas, like argon. Adjust the amperage for the material thickness. Practice on scrap pieces first. TIG welding requires skill. It’s ideal for detailed work. The welds are neat and strong. Suitable for automotive and artistic projects. Remember, safety is key. Always wear protective gear. Ensure good ventilation. Happy welding! “`Post-welding Treatments

Welding galvanized steel can be quite the task, and once you’re done, there’s still more to do! Post-welding treatments are essential to ensure the longevity and durability of your welded structure. This might seem like extra work, but trust me, it’s worth it. Let’s dive into some key post-welding treatments that you should know about.

Re-galvanizing Methods

After welding galvanized steel, the protective zinc coating around the weld area is often burned off. This leaves the steel vulnerable to rust and corrosion. Here are a few methods to re-galvanize and protect it:

- Hot-Dip Galvanizing: This is the most common method. The steel is dipped into molten zinc, which creates a thick, durable coating. It’s like giving your steel a new suit of armor!

- Cold Galvanizing: This involves applying a zinc-rich paint. It’s not as durable as hot-dip galvanizing, but it’s a good alternative for smaller projects or touch-ups.

- Thermal Spraying: In this method, zinc is melted and sprayed onto the steel. It’s a bit like spray painting but with molten metal. This method provides a decent level of protection.

Corrosion Protection

Re-galvanizing is not the only way to protect your welded steel from corrosion. Here are some additional steps you can take to ensure your steel stays in top shape:

- Use a Corrosion Inhibitor: These chemicals can be applied to the surface of the steel to slow down the corrosion process. Think of it as giving your steel a protective shield.

- Apply a Protective Coating: Paints, varnishes, and other coatings can provide an extra layer of protection. Make sure to choose a product that’s suitable for use on galvanized steel.

- Regular Maintenance: Inspect your welded structures regularly. Look for signs of rust or damage and address them promptly. It’s like giving your steel a regular health check-up.

By following these post-welding treatments, you can ensure that your galvanized steel remains strong and resistant to the elements. So next time you finish a welding project, remember: a little extra effort now can save a lot of trouble later!

Common Mistakes To Avoid

Welding galvanized steel involves some unique challenges. Avoiding common mistakes can make the process smoother and safer. Let’s look at some pitfalls to dodge.

Inadequate Preparation

One common mistake is not preparing the metal properly. Galvanized steel has a zinc coating that can cause issues when welding. Clean the steel thoroughly before starting. Remove the zinc coating from the weld area. Use a grinder or a chemical stripper for this step. If you don’t, it can produce toxic fumes. It also weakens the weld. Proper preparation ensures a stronger, safer weld.

Improper Ventilation

Another mistake is neglecting proper ventilation. Welding galvanized steel releases harmful zinc oxide fumes. These fumes are dangerous to breathe. Always work in a well-ventilated area. Use fans or exhaust systems to remove fumes. Wear a respirator mask to protect yourself. Poor ventilation can lead to serious health risks. Ensure your workspace has good airflow. This keeps you safe and healthy while welding.

Credit: www.reddit.com

Expert Tips For Successful Welding

Welding galvanized steel can be challenging. Galvanized steel has a zinc coating to prevent rust. This coating can cause issues during welding. With the right tips, you can achieve quality welds. Here are expert tips for successful welding of galvanized steel.

Choosing The Right Equipment

Select a welding machine suitable for galvanized steel. MIG and TIG welders are popular choices. Ensure your welder has adjustable settings. This helps control heat and prevent zinc fumes. Use a welding helmet with a high-quality filter. It protects your eyes from harmful rays. Gloves and protective clothing are also essential.

Best Practices For Quality Welds

Prepare the steel surface by removing the zinc coating. Use a wire brush or grinder for this task. Clean the area to remove any residue. This ensures a strong bond. Maintain proper ventilation in your workspace. Zinc fumes are hazardous. Position fans to direct fumes away from you.

Set your welder to a lower voltage. Higher heat can burn through the zinc coating. Use a steady hand to maintain a consistent weld. Move at a slow and controlled pace. This helps avoid gaps and weak spots. Check your welds for any defects. Re-weld if necessary for added strength.

Credit: galvanizeit.org

Frequently Asked Questions

What Happens If You Weld Galvanized Steel?

Welding galvanized steel releases toxic fumes, primarily zinc oxide. These fumes can cause metal fume fever, a flu-like condition. Ensure proper ventilation and use protective gear to minimize health risks. Always remove the zinc coating before welding to reduce hazardous exposure.

What Is The Best Way To Weld Galvanized Steel?

To weld galvanized steel, remove the zinc coating first. Use a grinder or chemical stripper. Weld with proper ventilation and protective equipment. Choose appropriate welding techniques like MIG or TIG. Clean the weld area thoroughly after completion.

Will A Mig Welder Weld Galvanised Steel?

Yes, a MIG welder can weld galvanized steel. Remove zinc coating from the weld area to avoid toxic fumes. Use proper ventilation and safety gear.

Is Galvanized Steel Harder To Weld?

Yes, galvanized steel is harder to weld. The zinc coating releases toxic fumes and can cause defects. Proper ventilation and surface preparation are essential.

Conclusion

Welding galvanized steel is possible with the right precautions. Always prioritize safety and proper ventilation. Remove the zinc coating before welding to avoid toxic fumes. Use the correct welding techniques and materials. Practice makes perfect, so take your time. With these tips, welding galvanized steel becomes easier.

Happy welding!