Building a welding table doesn’t have to break the bank. You can make a sturdy, functional table on a budget.

Many think a welding table needs to be expensive. But with some basic tools and materials, you can create an affordable solution. This guide will show you how to build a cheap welding table step-by-step. Whether you are a beginner or a seasoned welder, this DIY project is perfect for you.

You’ll save money and gain the satisfaction of crafting your own workspace. Plus, building your table lets you customize it to your needs. So, let’s dive into how you can construct a cost-effective welding table that doesn’t compromise on quality.

Credit: www.youtube.com

Choosing The Right Materials

Choosing the right materials for your welding table build is crucial. It ensures your project stays affordable and durable. The materials you choose impact the overall quality and longevity of your table. Let’s explore some affordable options and where you can source them.

Affordable Material Options

For a budget-friendly welding table, consider using mild steel. It’s strong, easy to weld, and cost-effective. You can also use scrap metal if you find pieces that suit your needs. Another option is using angle iron. It provides good support and is generally inexpensive. Plywood is another cheap option for the table top, but ensure it’s thick enough to handle your projects.

Where To Source Materials

Local hardware stores are a great start for sourcing materials. They often have sales or discounts on bulk purchases. Check out metal supply yards for scrap metal. They usually sell pieces at a fraction of the cost. Online marketplaces like Craigslist or Facebook Marketplace can also be good sources. People often sell leftover materials from their own projects. Don’t forget to visit recycling centers. They often have usable metal pieces at a lower cost.

Credit: rathasochenda.com

Designing Your Welding Table

Designing your welding table is an important step. A well-thought-out design can make your welding projects easier and more efficient. You want a table that suits your needs and fits your workspace. Let’s explore some key aspects of designing your welding table.

Essential Features

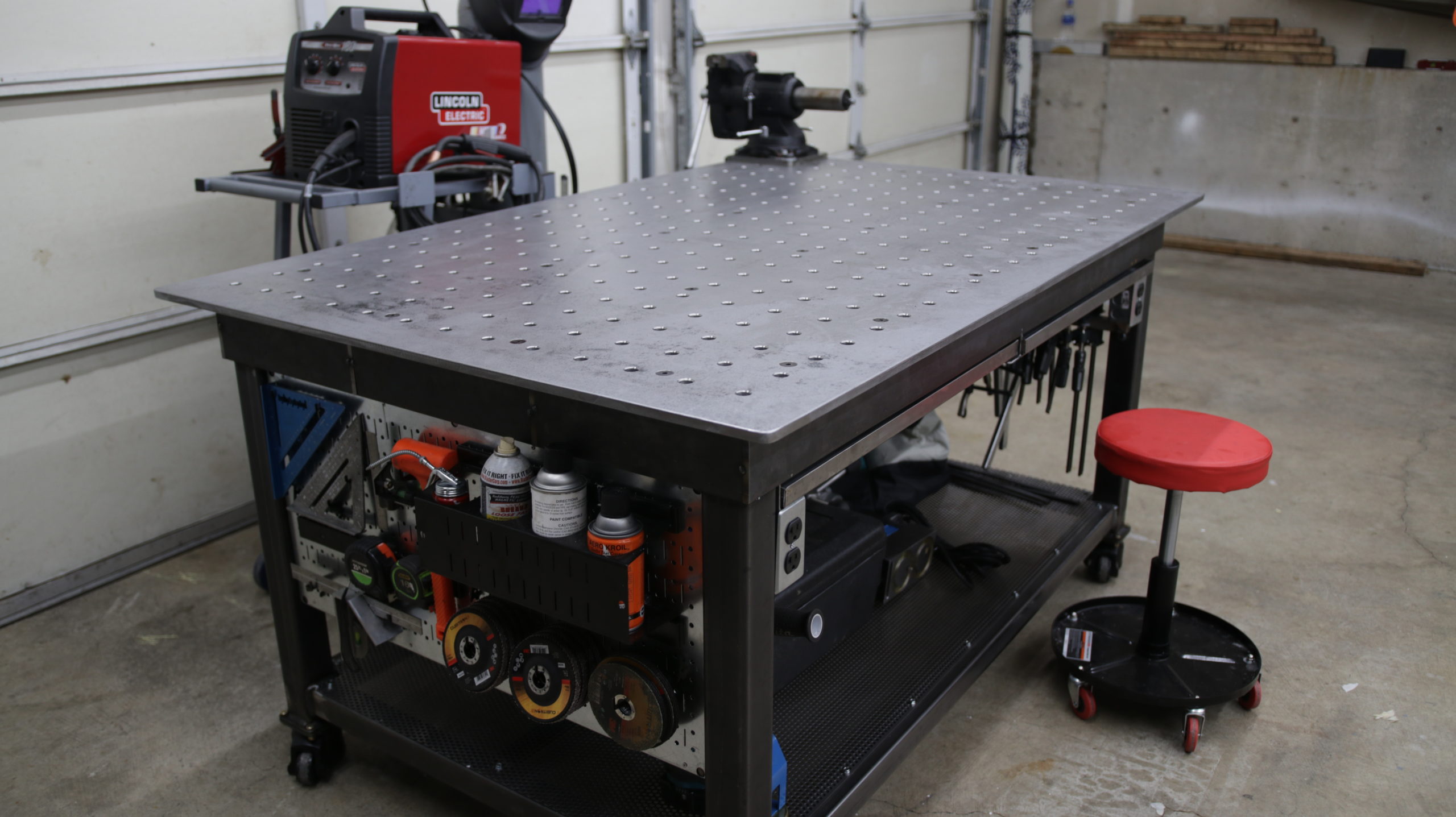

Every welding table needs a flat, sturdy surface. This helps ensure accuracy in your work. A metal top is the best choice. It withstands high heat and sparks. Stability is also crucial. The table should not wobble or move. Strong legs and a solid frame are necessary. Consider adding clamps or fixtures. These hold your workpieces in place. A fire-resistant base adds safety. This feature can prevent accidents in your workspace.

Customizable Options

Customizable options add versatility to your welding table. Adjustable height is one useful feature. It allows you to work comfortably, whether standing or sitting. Shelves and storage compartments help keep tools organized. This reduces clutter and improves efficiency. Adding wheels can make your table mobile. You can move it around your workspace as needed. Consider a detachable or foldable design. This saves space when the table is not in use. Personalize your table with paint or coatings. A rust-resistant coating can extend the table’s life. These options help you create a table that meets your specific needs.

Cutting And Preparing Materials

Building a cheap welding table at home can be an exciting project. The first step involves cutting and preparing the materials. This phase is crucial for creating a sturdy and functional table. Proper preparation ensures all pieces fit together perfectly. Below, we will discuss important safety tips and how to measure and mark your materials accurately.

Safety Tips

Always wear protective gear. This includes gloves, goggles, and a welding helmet. Clear the workspace of any flammable items. Ensure good ventilation to avoid inhaling harmful fumes. Use clamps to secure materials before cutting. This prevents slipping and accidents. Keep a fire extinguisher nearby. It’s better to be prepared for any emergencies.

Measurements And Marking

Accurate measurements are key to a successful build. Use a tape measure to mark the metal pieces. Make sure each piece aligns with your design plan. Use a marker or chalk for clear, visible lines. Double-check your measurements before cutting. This reduces the risk of errors. A square tool helps to ensure straight and precise lines.

Assembling The Table Frame

Assembling the table frame is a key step in building your welding table. This frame gives your table strength and stability. A strong frame ensures that your table can handle heavy tasks. Let’s dive into the process step-by-step.

Step-by-step Instructions

First, gather all necessary materials. This includes metal bars, a welding machine, and safety gear. Start by cutting the metal bars to the required lengths. Use a grinder or metal saw for this task.

Next, arrange the cut bars on a flat surface. Ensure they form a rectangular shape. Measure the angles with a square to confirm they are perfect 90-degree angles. Mark the points where the bars meet with chalk.

Then, tack weld the bars at each corner. This means welding small spots to hold the bars together. Check the angles again to make sure they have not shifted.

Securing Joints

Now, it’s time to secure the joints. Begin by welding along the seams where the bars meet. Use short, consistent welds for a strong bond. Move the welding torch steadily to avoid uneven welds.

After welding all seams, allow the frame to cool. Then, inspect the welds for any gaps or weak spots. If found, re-weld those areas to ensure strength.

Finally, clean the welds with a wire brush. This removes any slag and makes the joints smooth. Your table frame is now assembled and ready for the next steps.

Adding The Tabletop Surface

Adding the tabletop surface is a crucial step in your cheap welding table build. It determines the durability and usability of your table. Let’s explore the best materials and installation steps for your tabletop surface.

Choosing The Surface Material

Choosing the right surface material is vital. Steel is a popular choice. It is durable and can withstand heat. A 3/8-inch thick steel plate is ideal. It offers a flat and sturdy workspace. Another option is plywood. It is cheaper and easier to work with. But, it is less durable and might need frequent replacements.

MDF (Medium Density Fiberboard) can also work. It is smooth and easy to cut. Yet, it is not as strong as steel. For a good balance, you can use a steel sheet over MDF. This combination is both affordable and durable. Choose a material that fits your budget and needs.

Installation Process

Start by measuring your table frame. Cut your chosen material to match these dimensions. If using steel, you might need a metal cutter. For wood, a saw will work fine. Make sure the surface fits perfectly on the frame.

For steel surfaces, weld the plate to the frame. This will secure it firmly. For wood, use screws and bolts. Pre-drill holes to avoid splitting the wood. Attach the surface to the frame tightly.

Ensure the surface is level. Use a spirit level for accuracy. Adjust as needed before final tightening. Your tabletop is now ready for use.

Finishing Touches

Congratulations on building your welding table! Now, let’s focus on the finishing touches. These final steps will make your welding table durable and functional. We’ll cover painting and coating and adding accessories. These touches will make your project complete.

Painting And Coating

Start by cleaning the table surface. Remove any dust or debris. Use a wire brush to clean off any rust. Ensure the surface is smooth and ready for paint.

Choose a high-heat paint for the table. Apply a primer coat first. This helps the paint stick better. Once the primer is dry, apply the paint evenly. Use multiple thin coats for the best finish. Let each coat dry before adding the next one.

Consider using a clear coat for extra protection. This will make your table last longer. It also gives a nice shiny finish. Don’t rush this step. Proper painting can make a big difference.

Adding Accessories

Accessories can enhance your welding table. Consider adding clamps and vices. They hold your workpieces in place. This makes welding easier and safer.

Install a metal ruler along the edge. It helps measure your materials quickly. A magnetic strip is also useful. It keeps your tools within reach. These small additions improve your workflow.

Think about adding wheels to your table. This makes it easy to move around your workspace. Locking wheels are best. They keep the table stable while you work.

Finish by adding storage solutions. Shelves or hooks under the table keep your tools organized. A tidy workspace leads to better welding results. Enjoy your new, efficient welding table!

Maintenance And Care

Building a welding table on a budget can be a rewarding project. However, keeping it in good condition requires regular maintenance and care. In this section, we’ll dive into how to keep your welding table in tip-top shape. Whether you’re a hobbyist or a professional welder, these simple steps will help extend the life of your table and ensure it performs well for years to come.

Cleaning Tips

After each welding session, it’s important to clean your table. A clean surface ensures a safe and efficient work environment. Here are some easy cleaning tips:

- Remove Debris: Use a wire brush to remove welding slag, rust, and metal shavings. This prevents buildup and keeps your table smooth.

- Wipe It Down: A damp cloth with a bit of mild soap can help remove any remaining dirt or grease. Make sure to dry the surface completely to avoid rust.

- Use a Surface Cleaner: There are specific cleaners for metal surfaces. These can help maintain the table’s finish and prevent corrosion.

Remember, a clean table is a happy table! Regular cleaning will make your work easier and keep your table looking great.

Periodic Inspections

Inspecting your welding table periodically is crucial. Regular checks can catch small issues before they become big problems. Here’s what to look for:

- Check for Rust: Rust can weaken your table. Look for any signs of rust and treat it immediately with a rust remover or a bit of sanding.

- Inspect Welds: Make sure all welds are intact. Cracked or broken welds should be repaired to maintain the table’s strength.

- Examine the Surface: Look for any dents or warps. A flat surface is essential for precise welding. If you find any issues, consider repairing or replacing the affected part.

By performing these inspections, you’ll ensure that your welding table remains sturdy and reliable. It’s like giving your table a regular health check-up!

Maintaining a welding table doesn’t have to be a chore. With a little effort and regular care, your table will serve you well for many projects to come. Happy welding!

Credit: www.instructables.com

Frequently Asked Questions

What Can I Use For A Welding Table?

Use a sturdy steel or iron table for welding. Ensure it has a flat, non-flammable surface. Opt for a metal workbench with grounding options.

How Thick Does A Welding Table Need To Be?

A welding table should be at least 3/8 inch thick for general use. For heavy-duty projects, opt for 1/2 inch thick.

What Is The Best Surface For A Welding Table?

The best surface for a welding table is thick, flat steel. Steel provides durability and resists heat and sparks.

Do You Really Need A Welding Table?

Yes, a welding table is essential for precision, safety, and efficiency. It provides a stable, fire-resistant surface for welding tasks.

Conclusion

Building a cheap welding table is both rewarding and practical. You save money, learn new skills, and create a durable work surface. Follow the steps outlined, and you’ll have a sturdy table in no time. Don’t forget safety measures. Always wear protective gear.

A well-built table enhances your welding projects. Start today and enjoy the benefits of your own craftsmanship. Happy building!