Welding and bolting are common methods for joining steel structures. Each has its own benefits and drawbacks.

Choosing between welding and bolting depends on several factors. Both methods offer unique advantages and challenges. Welding provides a strong, seamless connection but requires skilled labor and can be time-consuming. Bolting, on the other hand, is faster and easier to inspect but may not offer the same level of strength.

Understanding the pros and cons of each method is crucial for making an informed decision. This comparison will help you determine which method is best suited for your specific project needs, ensuring safety and efficiency in steel construction.

Credit: www.quora.com

Welding In Steel Structures

Welding in steel structures offers strong, seamless connections. Bolting allows for easier assembly and disassembly. Welding requires skilled labor and can be more time-consuming. Bolting typically involves less specialized equipment, making it more accessible for various projects.

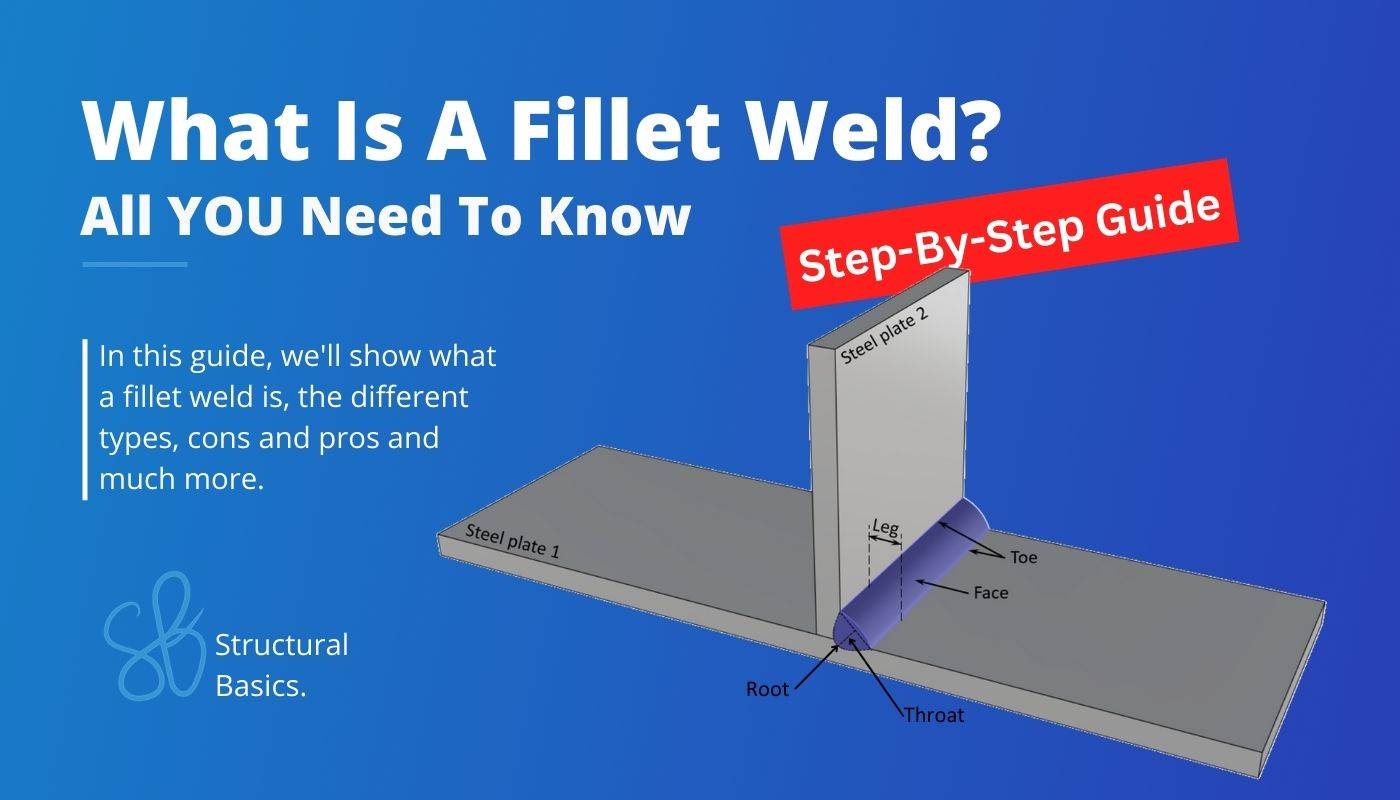

Welding is a crucial method in steel construction. It connects steel parts by melting them together. This process ensures a solid and durable bond. Welding offers several advantages and some drawbacks.Process Overview

Welding involves high heat to melt steel parts. Once cooled, the parts fuse into a single piece. This method creates strong and permanent joints. Welders must wear protective gear. They use special equipment to handle high temperatures.Types Of Welding Techniques

Different welding techniques exist for various needs. Each technique has unique features and benefits. 1. Arc Welding: This is the most common technique. It uses an electric arc to melt the metal. The process is efficient and versatile. 2. MIG Welding: Also known as Gas Metal Arc Welding (GMAW). It uses a continuous wire feed. This method is fast and produces clean welds. 3. TIG Welding: Also called Gas Tungsten Arc Welding (GTAW). It uses a tungsten electrode. This technique offers precision and high-quality welds. 4. Flux-Cored Welding: Similar to MIG welding. It uses a special tubular wire filled with flux. Ideal for outdoor work and thicker materials. 5. Spot Welding: Used for joining thin steel sheets. It applies pressure and heat to small areas. This method is quick and economical. Each welding technique suits specific tasks. Choose the right one based on project requirements. “`Bolting In Steel Structures

When it comes to building strong steel structures, there are two popular methods: welding and bolting. Today, we are going to zoom in on bolting. Bolting is like using screws to put together steel pieces. It’s a common technique in the construction world. But, what makes bolting a good choice? Let’s dive in!

Process Overview

Bolting is pretty straightforward. Imagine you are putting together a piece of furniture. You have steel pieces with holes in them, and you use bolts (which are like heavy-duty screws) to fasten them together. Here’s a quick look at the process:

- Preparation: Make sure all the pieces are cut to the right size and have the necessary holes.

- Alignment: Line up the holes of the steel pieces that need to be joined.

- Insertion: Insert the bolt through the aligned holes.

- Tightening: Use a wrench to tighten the bolt, securing the pieces together.

Easy as pie, right? Well, it’s a bit more technical, but you get the idea!

Types Of Bolting Techniques

Not all bolts are created equal. There are different techniques depending on the type of structure and the strength needed. Here are a few:

- Standard Bolting: This is the most common method. It involves regular bolts and nuts, and a wrench to tighten them.

- High-Strength Bolting: For structures that need extra strength, high-strength bolts are used. These bolts can handle more pressure.

- Preloaded Bolting: This technique is used when there is a need to reduce movement in the structure. The bolts are tightened to a precise amount of tension to keep the structure stable.

- Slip-Critical Bolting: This is a specialized technique used in structures that undergo a lot of stress. The bolts are tightened in a way that prevents any slip between the steel pieces.

Each technique has its place, depending on what you’re building. If you’re putting together a simple structure, standard bolting might be enough. For more complex buildings, you might need to go for high-strength or preloaded bolting.

So, there you have it! Bolting in steel structures is like putting together a big, heavy-duty puzzle with some very strong screws. It’s an essential method in construction, offering flexibility and strength. Ready to learn more? Let’s keep exploring!

Pros Of Welding

When it comes to steel structures, choosing the right method for joining parts is crucial. Welding and bolting are two popular techniques, each with its own advantages and disadvantages. In this section, we will explore the pros of welding, highlighting why it might be the best choice for your next project.

Strength And Durability

Welding creates a strong and durable bond between steel components. The process involves melting the edges of the parts to be joined, allowing them to fuse together as they cool. This results in a joint that is often stronger than the original materials. With welded joints, you can count on a solid and long-lasting connection.

Imagine building a bridge that needs to withstand heavy traffic and harsh weather. Would you trust a method that might loosen over time? I wouldn’t. Welding provides the peace of mind that the structure will remain intact and secure for many years to come.

Seamless Joints

One of the most appealing aspects of welding is the ability to create seamless joints. Unlike bolted connections, which can have visible gaps and potential weak points, welded joints are smooth and continuous. This not only enhances the strength of the structure but also gives it a cleaner and more aesthetically pleasing appearance.

Think about constructing a modern skyscraper. The sleek and polished look of the building is partly due to the seamless welded joints that hold it together. It’s like the difference between a finely tailored suit and one that’s been hastily thrown together with safety pins. Welding ensures that your project looks as good as it performs.

In summary, the pros of welding in steel structures are significant. With its unmatched strength, durability, and seamless joints, welding stands out as a reliable and visually appealing choice. So, the next time you’re faced with a decision between welding and bolting, consider these advantages and choose wisely.

Cons Of Welding

When it comes to constructing steel structures, welding and bolting are two common methods used to join metal parts. While both techniques have their advantages, it’s important to also consider their drawbacks. Let’s delve into the cons of welding, an essential aspect to weigh when deciding on the best method for your project.

Equipment And Skill Requirements

Welding, unlike bolting, requires specialized equipment and skilled labor. To successfully weld steel structures, one needs to invest in welding machines, safety gear, and other tools. This investment can be quite substantial, especially for small projects.

Furthermore, welding demands a high level of expertise. A welder must be trained and certified to ensure the welds are done correctly and safely. This means added costs for training or hiring certified professionals. Let’s face it, not everyone can just pick up a welding torch and create strong joints. It’s a skill that takes time and practice to master.

Inspection Challenges

Another downside to welding is the difficulty in inspecting the quality of the welds. Welds can have internal flaws such as cracks or voids that are not visible to the naked eye. Detecting these defects often requires advanced inspection techniques like ultrasonic testing or radiography, both of which are expensive and time-consuming.

Moreover, regular inspections are necessary to ensure the integrity of welded joints over time. This means ongoing maintenance costs, which can add up. Imagine discovering a hidden flaw in a critical weld years down the line—it could lead to catastrophic failures, and no one wants that headache!

In conclusion, while welding offers strong and permanent joints, it comes with significant equipment and skill requirements, and the challenges of inspecting welds can’t be ignored. Careful consideration of these factors is crucial in making an informed decision about whether welding is the right choice for your steel structure project.

Pros Of Bolting

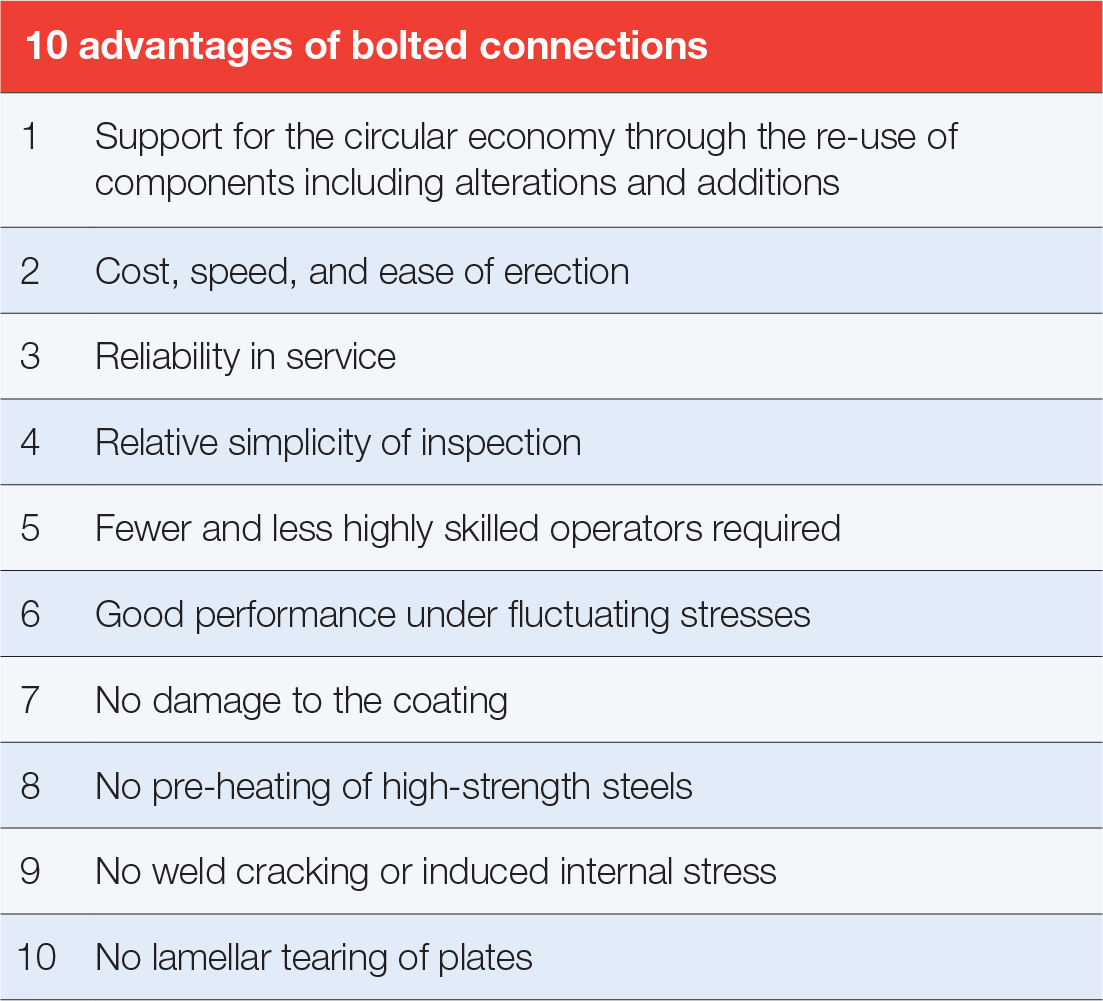

Bolting offers several advantages in steel structures. These benefits make it a popular choice for many construction projects. Let’s explore these benefits.

Ease Of Installation

Bolting is straightforward. Workers need basic training to perform bolting tasks. Bolting does not require specialized equipment. This simplicity reduces the overall installation time. It also minimizes labor costs. The process is less likely to have errors. This ensures a more reliable construction.

Flexibility And Adjustability

Bolted connections are flexible. They allow easy adjustments. If changes are needed, bolts can be loosened and tightened again. This adjustability is crucial in dynamic environments. It also simplifies the process of making modifications or repairs. Bolting makes it easy to align parts during assembly. This flexibility ensures the structure meets precise specifications.

Credit: www.structuralbasics.com

Cons Of Bolting

Bolting in steel structures has its advantages, but it also comes with drawbacks. Understanding the cons of bolting can help in making better decisions for construction projects. Let’s delve into some key issues associated with bolting.

Potential For Loosening

Bolt connections can loosen over time. Vibrations and dynamic loads can cause bolts to lose their tightness. Regular maintenance is needed to check and re-tighten bolts. This can increase the time and cost involved in maintaining steel structures.

Corrosion Issues

Bolts are vulnerable to corrosion. Exposure to moisture and chemicals can lead to rust. Corroded bolts lose strength and may fail. Protecting bolts from corrosion involves extra coatings and treatments. These additional steps can add to the overall project cost.

Choosing Between Welding And Bolting

Welding provides strong, permanent joints but requires skilled labor and safety precautions. Bolting allows for easy assembly and disassembly, though it may be less durable.

Selecting the right method for joining steel structures is crucial. Welding and bolting are the two primary methods. Each has its own advantages and drawbacks.Factors To Consider

Choosing between welding and bolting depends on several factors. These include the type of structure, environmental conditions, and load requirements. Welding offers strong, permanent joints. Bolting allows for easy assembly and disassembly. Budget is another key factor. Welding can be more expensive due to labor and equipment costs. Bolting might be cheaper but requires more maintenance over time. Safety is also important. Welding involves high heat and potential hazards. Bolting is generally safer and easier for workers.Application-specific Recommendations

For large, permanent structures, welding is often preferred. It provides strong and durable joints. For temporary or modular structures, bolting is a better choice. It allows for quick assembly and disassembly. In seismic zones, bolted connections can absorb shocks better. For structures exposed to harsh weather, welded joints offer better protection. Each method has its place in steel construction. Understanding the pros and cons helps in making an informed decision. “`

Credit: designmanual.gaa.com.au

Frequently Asked Questions

What Are The Advantages And Disadvantages Of Welding Over Bolting?

Welding offers stronger joints and better sealing. It is more durable and aesthetically pleasing. Bolting allows for easier disassembly and maintenance. It is quicker and often cheaper. Welding requires skilled labor and can be time-consuming. Bolted joints may loosen over time and are less resistant to vibrations.

What Is The Difference Between Welding And Bolting Steel Structures?

Welding fuses steel parts together by melting them. Bolting connects steel parts using bolts and nuts. Welding offers stronger joints but is permanent. Bolting allows for disassembly and adjustments.

What Are The Advantages And Disadvantages Of Bolted Connection?

Bolted connections offer easy installation, disassembly, and adjustability. They provide strong, reliable joints. Disadvantages include potential loosening under vibrations and the need for precise hole alignment.

Why Use Bolts Instead Of Welding?

Bolts allow for easy disassembly and reassembly. They provide flexibility for maintenance and future modifications. Bolting avoids heat distortion issues.

Conclusion

Choosing between welding and bolting depends on your project needs. Welding offers strength and seamless joints. Bolting provides flexibility and easy disassembly. Welded connections are ideal for permanent structures. Bolted joints suit temporary or adjustable frameworks. Both methods have their pros and cons.

Consider cost, time, and structural requirements. Select the best fit for your steel structure. Make informed decisions for optimal results.