Calculating welding costs and requirements can seem complex at first. It’s essential to get accurate measurements for successful projects.

Understanding the basics of welding calculation helps ensure precision and efficiency. Whether you’re a beginner or a seasoned professional, knowing how to calculate welding is a crucial skill. This process involves determining the amount of materials, time, and costs involved.

By breaking down the steps, you can avoid mistakes and save resources. This guide will walk you through the essential aspects of welding calculation. You’ll learn how to measure, estimate, and plan your welding projects effectively. Let’s dive into the world of welding calculations and simplify this important task.

Introduction To Welding Costs

Understanding welding costs is crucial for project planning and budgeting. Accurate cost calculations ensure efficient resource allocation. They also help in avoiding unexpected expenses. This section will explore the importance of welding cost calculation and the factors that affect it.

Importance Of Cost Calculation

Calculating welding costs accurately is essential for several reasons. It helps in estimating the total project cost. This allows better financial planning. It also ensures the project stays within budget. Clients appreciate transparency in costs. This builds trust and credibility. Accurate cost calculations also help in comparing different welding methods. This ensures the selection of the most cost-effective option.

Factors Affecting Costs

Several factors influence welding costs. The type of welding process is a major factor. Different welding methods have varying costs. The cost of materials also impacts the overall expense. High-quality materials may cost more but ensure durability. Labor costs play a significant role too. Skilled welders may charge higher rates. The project size and complexity affect costs as well. Larger, complex projects often require more resources and time. Equipment and maintenance costs can add to the expenses. Regular maintenance ensures equipment efficiency but incurs costs. Lastly, location can influence welding costs. Some areas have higher labor and material costs.

Credit: www.chegg.com

Types Of Welding Processes

Understanding the various types of welding processes is essential for both beginners and professionals. Each process has its unique features and applications. Let’s explore some of the most common types of welding processes.

Arc Welding

Arc welding uses an electric arc to create heat. This heat melts and fuses metals together. It is widely used because it is versatile and efficient. It is suitable for both heavy and light tasks. Common types include Shielded Metal Arc Welding (SMAW) and Flux-Cored Arc Welding (FCAW).

Mig Welding

MIG welding stands for Metal Inert Gas welding. It uses a continuous wire feed. This wire acts as an electrode and filler material. Shielding gas protects the weld from contamination. MIG welding is popular for its speed and ease of use. It is ideal for beginners and large-scale projects.

Tig Welding

TIG welding stands for Tungsten Inert Gas welding. It uses a non-consumable tungsten electrode. This process provides high-quality and precise welds. Shielding gas, usually argon, protects the weld area. TIG welding is perfect for thin materials and detailed work. It requires more skill and practice.

Other Techniques

Other welding techniques include oxy-acetylene welding, which uses a gas flame. This method is less common but useful for cutting and brazing. Spot welding joins metal sheets using pressure and heat from an electric current. Laser welding is precise and used in the automotive and medical industries. Each technique has its specific use and benefits.

Material Costs

When it comes to welding, understanding the costs involved is crucial. One of the biggest expenses is the material cost. This includes the type of metal you’re using, the consumables needed, and how you manage waste. Let’s dive into each of these in more detail.

Metal Types

The type of metal you choose greatly affects your overall cost. Different metals have different prices. For instance:

| Metal Type | Cost per kg |

|---|---|

| Steel | $2 |

| Aluminum | $3 |

| Stainless Steel | $4 |

So, if you’re welding aluminum, expect to pay more than if you’re working with steel. Always check current market prices as they can change.

Consumables

Consumables are the items that get used up during the welding process. This includes:

- Welding rods

- Welding wire

- Shielding gas

These items can add up quickly. For example, a roll of welding wire might cost $50, and a cylinder of shielding gas could be $100. Keep track of these costs to avoid any surprises.

Waste Management

Waste management is another important factor. When you weld, there’s always some waste. This could be leftover metal pieces or used consumables. Efficient waste management can save you money.

Here are a few tips:

- Recycle scrap metal

- Reuse what you can

- Dispose of waste properly

By managing waste well, you not only save money but also help the environment. And who doesn’t like a win-win situation?

In conclusion, understanding material costs in welding helps you budget better. Keep an eye on metal prices, track your consumables, and manage waste efficiently. This way, you can keep your project on track and within budget.

Labor Costs

Understanding labor costs in welding is crucial. It helps in budgeting and planning. It also ensures accurate project cost estimates. Several factors influence labor costs in welding.

Welding Time

Welding time directly impacts labor costs. The longer the welding process, the higher the labor cost. Estimate the time needed for the entire welding job. Consider the preparation time, actual welding time, and finishing touches. Accurate time estimation helps in managing labor costs effectively.

Skill Level

The skill level of the welder plays a significant role. Highly skilled welders command higher wages. They work faster and produce better quality welds. On the other hand, less experienced welders may take more time. Their lower wages balance out their slower pace. Always consider the complexity of the welding job. Hire welders with appropriate skill levels for the best results.

Labor Rates

Labor rates vary based on location and industry standards. Research the average labor rates in your area. This helps in setting a fair wage for the welders. Consider the welder’s experience and the job’s complexity. A balanced approach ensures competitive pricing and high-quality work.

Equipment Costs

Calculating welding costs involves many factors. One major factor is equipment costs. This includes the price of the welding machine, maintenance costs, and depreciation. Understanding these costs helps in making informed decisions.

Machine Purchase

The first cost to consider is the machine purchase. Welding machines come in various types and prices. Choose one that fits your needs and budget. Remember, a higher initial cost may mean better quality and efficiency.

Maintenance

Regular maintenance is crucial for welding machines. It helps prevent breakdowns and extends the machine’s life. Include the cost of spare parts and labor in your budget. Scheduled check-ups can save money in the long run.

Depreciation

Depreciation affects the value of your welding machine over time. Each year, the machine loses some of its value. Calculate this loss to understand the machine’s worth. This helps in planning for future replacements.

Credit: www.arcraftplasma.com

Energy Costs

When calculating welding costs, energy consumption is a crucial factor. Energy costs can significantly impact the overall expense of a welding project. In this section, we will break down the energy costs into two main components: electricity usage and fuel consumption.

Electricity Usage

Welding machines often run on electricity. This means the cost of electricity can add up quickly. To estimate your electricity costs, follow these steps:

- Find the power rating of your welding machine. This is usually in kilowatts (kW).

- Determine the hours of usage. How many hours will the machine run?

- Check your electricity rate. This is usually in cents per kilowatt-hour (kWh).

Here’s a simple formula to calculate electricity costs:

Electricity Cost = Power Rating (kW) × Hours of Usage × Electricity Rate (cents per kWh)

For example, if your welding machine has a power rating of 5 kW, runs for 10 hours, and your electricity rate is 15 cents per kWh, the cost would be:

Electricity Cost = 5 kW × 10 hours × 15 cents/kWh = 750 cents or $7.50

So, for 10 hours of welding, you will spend $7.50 on electricity. Pretty straightforward, right?

Fuel Consumption

Some welding processes use fuel instead of electricity. This includes gas welding, where fuel like acetylene or propane is used. Let’s break down how to calculate fuel costs:

- Identify the type of fuel you are using.

- Determine the fuel consumption rate. How much fuel does your welding process use per hour?

- Check the current price of the fuel.

Use this formula to calculate fuel costs:

Fuel Cost = Fuel Consumption Rate × Hours of Usage × Fuel Price

For instance, if you use acetylene with a consumption rate of 1.5 gallons per hour, weld for 8 hours, and the acetylene costs $3 per gallon, the cost would be:

Fuel Cost = 1.5 gallons/hour × 8 hours × $3/gallon = 36 dollars

Thus, for 8 hours of welding, you will spend $36 on fuel. Simple, isn’t it?

By understanding and calculating these energy costs, you can better manage your welding expenses. Keeping an eye on electricity and fuel usage helps you stay within budget and avoid any nasty surprises.

Calculating Total Welding Costs

Calculating total welding costs is crucial for budgeting and planning. It helps identify the most cost-effective methods. By understanding the components, one can optimize welding processes and reduce expenses. Below, we outline a step-by-step guide and common mistakes to avoid.

Step-by-step Guide

First, calculate labor costs. Multiply the welder’s hourly rate by the hours worked. Next, consider the cost of welding consumables. Include electrodes, filler metals, and shielding gas. Factor in the cost of electricity used. Multiply the kilowatt-hours by the electricity rate.

Then, add equipment costs. Include depreciation, maintenance, and rentals. Calculate overhead costs. This includes administrative expenses and facility costs. Finally, sum all these expenses. This gives the total welding cost.

Common Mistakes

One common mistake is ignoring hidden costs. These include equipment downtime and material waste. Another mistake is underestimating labor costs. Always consider setup and cleanup times.

Overlooking safety expenses is also a common error. Proper safety gear and training are essential. Not accounting for these can lead to inaccurate cost calculations. Stay thorough to ensure precise welding cost estimation.

Credit: www.howtoresistanceweld.info

Useful Tools For Cost Calculation

Calculating welding costs can feel like a daunting task, but with the right tools, it can become much simpler. Whether you’re a seasoned professional or just starting out, understanding the costs involved is crucial. Here, we’ll explore some useful tools for cost calculation, including software options and manual methods.

Software Options

There are several software options available that can help you calculate welding costs with ease. These tools are designed to simplify the process and provide accurate results.

- Weld Cost Calculator: This tool can be a lifesaver. It allows you to input various parameters like material type, labor rates, and welding speed. The software then calculates the total cost for you.

- Welding Estimation Software: Another great option, this software offers a range of features including cost estimation, project management, and material tracking. It’s like having a virtual assistant for your welding projects.

- FabSuite: Known for its user-friendly interface, FabSuite helps in detailed cost analysis. It can break down costs into materials, labor, and overheads, giving you a clear picture of where your money is going.

Using software can save you time and reduce the risk of errors. It’s particularly useful for larger projects where manual calculations can become overwhelming.

Manual Calculation Methods

For those who prefer the traditional approach, manual calculation methods are still a reliable option. While they may require a bit more effort, they can be just as effective.

- Pen and Paper: Sometimes, the old-fashioned way is the best. Grab a pen and paper and start by listing all the materials you’ll need. Include their costs and quantities. Next, factor in labor costs based on the time required for the job.

- Excel Spreadsheets: If you prefer a slightly more modern approach, Excel can be your best friend. Create a spreadsheet to track all your expenses. Use formulas to automatically calculate totals and adjust for any changes in costs.

- Cost Estimation Tables: Many welding manuals include cost estimation tables. These tables can help you quickly determine costs based on various factors like material thickness and welding speed. It’s a handy reference to have by your side.

Manual methods give you a deeper understanding of the cost components and allow for flexibility. Plus, there’s a certain satisfaction in doing the math yourself, isn’t there?

Whether you choose software or manual methods, having the right tools can make a world of difference in calculating welding costs. Find what works best for you and stick with it. After all, the goal is to make your welding projects as efficient and cost-effective as possible.

Tips For Reducing Welding Costs

Welding can be an expensive process, but there are ways to save money without sacrificing quality. By adopting efficient practices and cost-saving techniques, you can reduce welding costs significantly. Let’s explore some practical tips that can help you achieve this.

Efficient Practices

Efficiency is key when it comes to welding. Here are some straightforward practices to improve your welding efficiency:

- Plan Before You Weld: Planning your welding process can save a lot of time and material. Sketch out your design and think through each step before starting.

- Use the Right Equipment: Ensure you’re using the correct welding machine and tools for the job. Using the wrong equipment can lead to mistakes and wasted materials.

- Maintain Your Equipment: Regular maintenance of your welding machines and tools can prevent breakdowns and ensure smooth operations.

- Train Your Welders: Proper training reduces errors. Skilled welders work faster and produce higher quality welds, saving you time and materials.

Cost-saving Techniques

Saving costs doesn’t mean cutting corners. It’s about being smart with your resources. Here are some practical techniques to help you save:

- Buy in Bulk: Purchasing welding materials in bulk can often reduce costs. Just ensure you have proper storage to keep the materials in good condition.

- Reuse Scrap Metal: Don’t throw away scrap metal. It can often be reused for smaller welding projects or practice pieces.

- Optimize Welding Speed: Adjust your welding speed to be efficient but not too fast to avoid mistakes. This balance can save time and reduce material waste.

- Choose the Right Consumables: Different welding processes use different consumables (like electrodes or filler metals). Selecting the right type and size can reduce waste and improve efficiency.

Implementing these tips can lead to substantial savings in your welding projects. Remember, the goal is to work smarter, not harder. By planning ahead, using the right tools, and making smart decisions, you can reduce your welding costs effectively.

Frequently Asked Questions

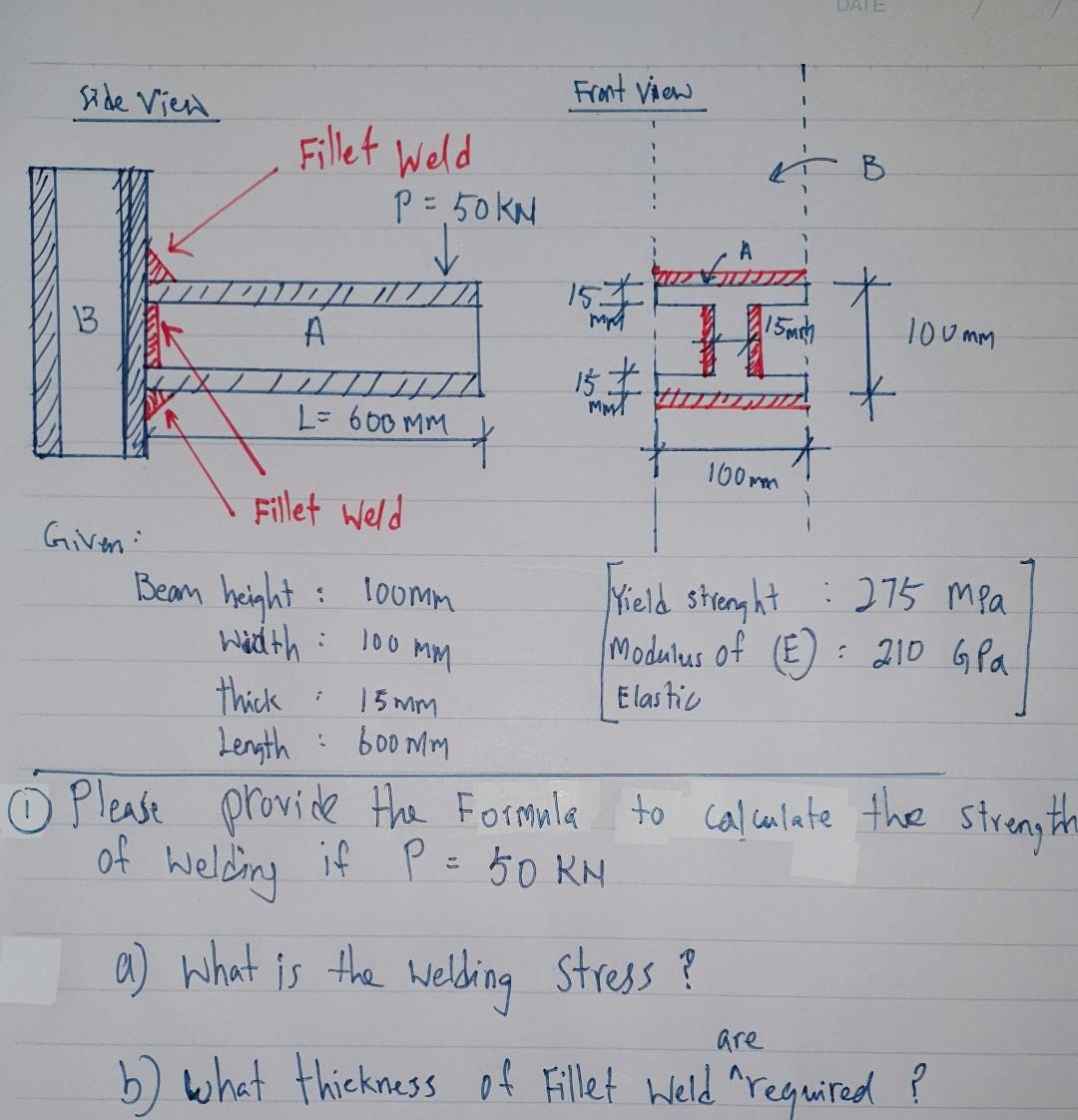

What Is The Formula For Calculating Welds?

The formula for calculating welds is: Weld Volume = Throat Area x Weld Length. The throat area depends on the weld type and size.

How Do You Calculate The Welding Rate?

To calculate the welding rate, divide the total length of weld by the total welding time. Ensure accurate measurements for both length and time to get a precise rate.

What Is A Welding Calculator?

A welding calculator is a tool that helps estimate welding costs, material usage, and parameters for welding projects. It simplifies planning and budgeting.

How To Calculate The Welding Size?

To calculate welding size, measure the thickness of the materials being joined. Determine the appropriate weld size based on industry standards. Use welding symbols and tables for reference. Ensure accuracy to maintain strength and safety.

Conclusion

Calculating welding costs can seem daunting, but it’s manageable with practice. Break down the steps. Measure the materials, consider labor, and calculate overheads. Use welding calculators for precision. Practice regularly to improve accuracy. Remember, preparation is key. Double-check calculations to avoid mistakes.

Keep learning and refining your skills. This will ensure accurate welding cost estimations. Happy welding!