Calculating welding travel speed is essential for quality welds. It ensures consistency and strong joints.

Welding travel speed measures how fast you move the welding torch along the weld path. This factor affects the weld’s appearance and strength. Incorrect speed can lead to weak welds or burn-through. To achieve perfect welds, you must understand and calculate the correct travel speed.

This guide will walk you through the steps and considerations. By the end, you’ll be able to calculate welding travel speed with confidence. Whether you’re a beginner or experienced welder, mastering this skill is vital. Let’s dive in and explore how to get your welding travel speed just right.

Introduction To Welding Travel Speed

Welding travel speed is how fast you move the welding torch or electrode along the weld joint. This speed is key to making strong and good-looking welds. But why does it matter so much? Let’s dive in and find out.

Importance Of Welding Travel Speed

The speed at which you weld affects many things. First, it controls how much heat you put into the metal. If you go too slow, you might burn through the material. Go too fast, and the weld might not stick well. So, finding the right speed is like finding the sweet spot.

Imagine riding a bicycle. If you ride too slow, you wobble and might fall. If you ride too fast, you could crash. Welding is similar. You need to find a balance to make sure everything goes smoothly.

Impact On Weld Quality

Welding travel speed greatly impacts weld quality. When speed is just right, you get a strong weld with nice, even beads. Too slow, and you get a big, messy weld. Too fast, and the weld might be weak and full of gaps.

Here’s a little joke for you: Why did the welder bring a ladder to work? Because he wanted to take his welding to the next level! Just like a welder aiming for the next level, getting the travel speed right is crucial for quality work.

To sum it up, mastering welding travel speed is like mastering a new language. It takes practice, patience, and a bit of trial and error. But once you get it, your welds will be top-notch.

Factors Influencing Travel Speed

Calculating welding travel speed involves various factors. Each factor affects the final result. Understanding these factors helps achieve accurate welding. This ensures strong and reliable welds.

Material Type

Different materials have different melting points. Some metals, like aluminum, melt quickly. Others, like stainless steel, take longer. The material’s thickness also matters. Thicker materials need slower travel speeds. This allows proper melting and bonding. The material’s surface condition also influences speed. Clean surfaces weld faster than dirty ones.

Welding Process Used

The welding process impacts travel speed. MIG welding often requires faster speeds. TIG welding is slower, allowing more control. Stick welding speed varies with electrode type. Automated welding systems have consistent speeds. Manual welding depends on the welder’s skill. Different processes suit different projects. Choose the right one for the job.

Tools Needed For Calculation

Calculating welding travel speed accurately is essential for achieving quality welds. To do this, you will need some essential tools. These tools will help you measure and calculate the travel speed with precision. Let’s dive into the specific tools required.

Measuring Devices

Measuring devices are your best friends when it comes to calculating welding travel speed. Here are some common tools you might need:

- Stopwatch: Used to measure the time taken to complete a weld.

- Tape Measure: Helps in measuring the length of the weld.

- Ruler or Caliper: Provides precise measurements of the weld bead size.

Using these tools, you can calculate the welding travel speed with the simple formula: Travel Speed = Length of Weld / Time Taken. So, grab your stopwatch and tape measure, and you are good to go!

Software And Apps

In today’s digital age, there’s an app for almost everything, and welding is no exception. Several software and mobile apps can aid in calculating welding travel speed. Here are a few you might find handy:

- Welding Speed Calculator Apps: These apps are designed to make your life easier. Simply input the length of the weld and the time taken, and the app will do the math for you.

- CAD Software: Computer-Aided Design (CAD) software can also be used to simulate and calculate welding parameters, including travel speed.

- Online Calculators: Numerous websites offer free welding calculators that can compute travel speed based on your inputs.

Using these digital tools can save you time and ensure accuracy, especially if math isn’t your strong suit!

Basic Formula For Travel Speed

Calculating welding travel speed is crucial for ensuring strong, precise welds. The travel speed affects the quality and consistency of the weld. Knowing how to calculate it can help you achieve better results. Let’s dive into the basic formula for travel speed in welding.

Understanding The Components

The travel speed formula includes a few key components. These are the length of the weld, the time taken to complete the weld, and the units of measurement. Knowing these components helps in achieving a consistent weld.

The length of the weld is the total distance covered by the welding torch. The time taken is the duration from the start to the end of the weld. These components are essential for accurate calculations.

Step-by-step Calculation

First, measure the length of the weld in inches or millimeters. Use a tape measure for accuracy. Record the length for reference.

Next, track the time taken to complete the weld. Use a stopwatch to get precise timing. Note the time in seconds or minutes.

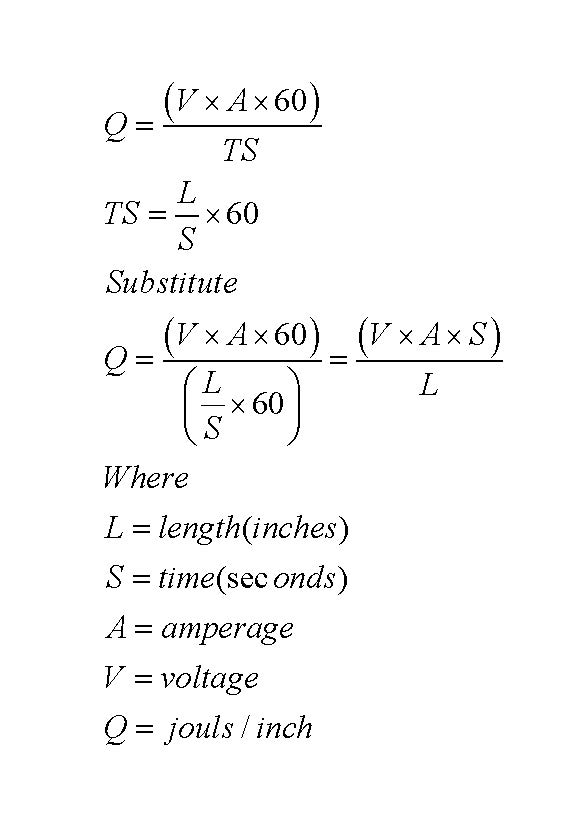

Finally, divide the length of the weld by the time taken. This gives you the travel speed. The formula looks like this:

Travel Speed (in/min or mm/min) = Length of Weld / Time Taken

For example, if the weld length is 10 inches and the time taken is 2 minutes, the travel speed is 5 inches per minute.

Understanding this basic formula helps in maintaining consistent weld quality. Practice makes it easier and more accurate over time.

Practical Methods For Measuring

Calculating welding travel speed can be a bit tricky, but it’s essential for achieving quality welds. There are a couple of practical methods to measure it. Some techniques require just a few basic tools, while others involve more sophisticated equipment. Let’s explore both manual and automated methods for measuring welding travel speed.

Manual Techniques

Manual methods are straightforward and require minimal equipment. They are perfect for beginners or when you’re working in a low-tech environment. Here’s how you can do it:

- Stopwatch and Tape Measure: The simplest way is to use a stopwatch and a tape measure. Start welding and at the same time, start the stopwatch. Once you finish the weld, stop the timer. Measure the length of the weld and divide it by the time taken. Voila, you have your travel speed!

- Chalk and Marker: Mark your starting point and ending point with chalk or a marker. Measure the distance between these points. Again, use a stopwatch to time how long it takes to weld from start to finish. Calculate the speed by dividing the distance by the time.

These methods are simple but can be very effective. They require a bit of practice and steady hands, but with time, you can become quite accurate.

Automated Systems

If you have access to more advanced tools, automated systems can make measuring welding travel speed much easier and more precise.

- Welding Data Loggers: These devices attach to your welding equipment and automatically record travel speed, along with other parameters like voltage and current. They offer a high level of accuracy and can store data for future analysis.

- Laser Tracking Systems: High-tech and highly accurate, these systems use lasers to track the movement of the welding torch. They can provide real-time data on travel speed, allowing for instant adjustments if needed.

Automated systems are great for professional welders or industrial settings where precision is key. They can be a bit pricey but are worth the investment if you’re serious about welding.

So, whether you’re a novice welder with just a stopwatch and tape measure, or a seasoned pro with access to advanced equipment, there are practical methods available for measuring welding travel speed. Choose the one that fits your needs and get welding!

Credit: www.weldingandndt.com

Common Mistakes To Avoid

Calculating welding travel speed is crucial for ensuring quality welds. Mistakes can lead to weak joints or unnecessary costs. By avoiding common errors, you can achieve better results. Let’s explore some mistakes that are easy to avoid.

Incorrect Measurements

Accurate measurements are vital for precise welding travel speed. Many welders rely on guesswork. This can lead to errors. Always use proper tools for measurements. A tape measure or digital caliper works best. Double-check your measurements before welding. This step ensures you start correctly.

Ignoring Material Differences

Different materials require different welding speeds. Many welders ignore this fact. Steel, aluminum, and stainless steel behave differently. Understanding material properties helps in setting the right speed. Always consult material guidelines. Adjust your speed based on the material you are working with.

Optimizing Travel Speed

When it comes to welding, travel speed is one of the most critical factors that can make or break your project. Optimizing travel speed isn’t just about moving the torch from point A to point B as fast as you can. It’s about finding that perfect balance to achieve strong, clean welds. Let’s dive into how you can adjust your travel speed to ensure top-notch results.

Adjusting For Different Materials

Not all materials are created equal, and neither is their welding process. The travel speed you use for welding steel won’t necessarily work for aluminum or titanium. Why? Because each material has its own set of properties that affect how it melts and bonds.

- Steel: Generally, you can use a slower travel speed with steel. This allows the heat to penetrate deeply, ensuring a strong weld.

- Aluminum: Aluminum requires a faster travel speed. This prevents the material from overheating and becoming too weak.

- Titanium: For titanium, you need to be extra cautious. This material demands a precise balance of speed and heat to avoid contamination.

So, always adjust your travel speed based on the material you’re working with. It’s like cooking: you wouldn’t cook a steak and a fish fillet at the same temperature, would you?

Fine-tuning For Quality

Even after adjusting for different materials, you might find that your welds still aren’t perfect. This is where fine-tuning comes in. Small tweaks to your travel speed can make a huge difference in the quality of your welds.

- Observe the Weld Pool: Pay attention to the weld pool. If it’s too large, you’re moving too slowly. If it’s too small, you’re going too fast.

- Consistency: Keep your speed consistent. Uneven travel speed can lead to weak spots in your weld.

- Practice: Practice makes perfect. The more you weld, the better you’ll understand the nuances of travel speed.

Remember, even the best welders had to start somewhere. Don’t get discouraged if your first few attempts aren’t perfect. Keep adjusting and fine-tuning, and soon you’ll find that sweet spot.

In conclusion, optimizing your welding travel speed is a blend of science and art. It requires understanding the material, making adjustments, and fine-tuning your technique. With patience and practice, you’ll be laying down perfect beads in no time. So grab your torch, get welding, and watch your skills—and confidence—grow.

Credit: app.aws.org

Expert Tips And Best Practices

Calculating welding travel speed can be challenging. Knowing expert tips and best practices helps. These strategies ensure high-quality welds and effective work. Let’s explore some crucial tips.

Maintaining Consistency

Consistency in welding travel speed is vital. It ensures uniform weld quality. Keep a steady hand and pace. Avoid sudden changes in speed. These can lead to weak welds.

Use visual markers to guide your speed. This helps maintain a consistent pace. Practice regularly to develop a steady hand. Consistency comes with experience.

Regular Calibration Of Tools

Regularly calibrate your welding tools. Calibration ensures accurate readings. This affects your travel speed calculations. Inaccurate tools can lead to errors.

Check your tools before starting any project. Make calibration a routine task. Well-calibrated tools lead to precise work. This saves time and reduces mistakes.

Case Studies And Real-world Examples

Understanding welding travel speed is crucial in various industries. Real-world examples and case studies provide valuable insights into practical applications. These examples highlight the importance of accurate calculations and their impact on the final product.

Industry Applications

The automotive industry often relies on precise welding travel speed. This ensures the durability and safety of vehicle parts. For instance, a leading car manufacturer noticed defects in their chassis. Upon investigation, they found inconsistencies in welding travel speed. Adjusting the speed reduced defects and improved overall quality.

In the construction industry, welding travel speed plays a vital role. Consider a company building a high-rise structure. They faced delays due to slow welding processes. By optimizing travel speed, they completed the project on time. This saved costs and met safety standards.

Lessons Learned

Accurate welding travel speed is not just a technical requirement. It directly affects product quality and project timelines. One lesson from real-world cases is the importance of regular monitoring. Consistent checks help maintain optimal welding conditions.

Another lesson is training. Skilled welders understand the impact of travel speed. They can adjust techniques based on material and project needs. This adaptability ensures consistent results and high-quality output.

These case studies emphasize the importance of precision in welding. Calculating and maintaining the right travel speed is key. It ensures safety, quality, and efficiency in various industries.

Credit: www.weldingandndt.com

Frequently Asked Questions

What Is The Formula For Travel Speed In Welding?

The formula for travel speed in welding is: Travel Speed = Length of Weld / Time Taken. Measure the length in inches or millimeters and the time in minutes.

What Is The Formula For Travel Speed?

The formula for travel speed is: Speed = Distance ÷ Time. Calculate speed by dividing the distance traveled by the time taken.

How Do You Calculate Weld Speed?

Calculate weld speed by dividing the length of the weld by the welding time. Ensure units are consistent for accuracy.

How To Calculate Average Travel Speed?

To calculate average travel speed, divide the total distance by the total time taken. Use the formula: Speed = Distance / Time.

Conclusion

Calculating welding travel speed is crucial for quality work. It ensures strong welds. Use a stopwatch and measure the distance. Practice to improve accuracy. Always maintain a steady hand. This keeps the weld consistent. Follow these steps to achieve better results.

Your welding projects will benefit greatly. Happy welding!