Welding processes can be complex to understand. But classifying them helps simplify things.

Welding is a crucial skill in many industries. From construction to automotive, it plays a vital role. But with so many types of welding, how do you classify them? Knowing the classifications can help you choose the right process for your needs.

It can also improve safety and efficiency. In this blog, we will explore the main types of welding processes. We’ll break down the criteria used to classify them. By the end, you’ll have a clear understanding of welding classifications. This knowledge can aid in making informed decisions in your projects. Let’s dive in and unravel the world of welding processes.

Introduction To Welding Classification

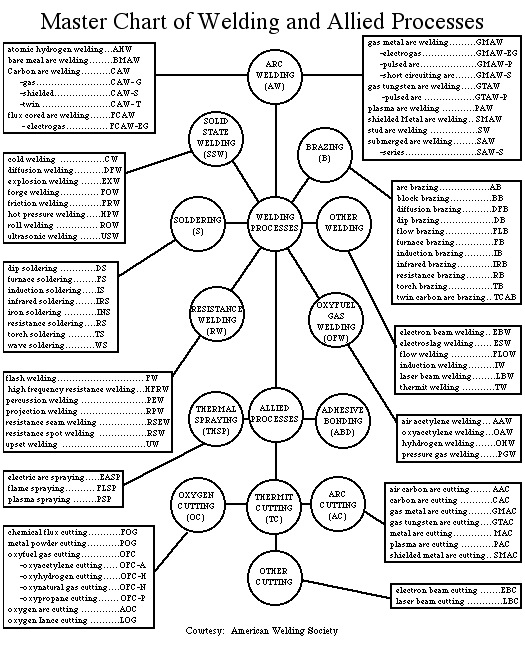

Welding processes are classified based on the energy source used. Common types include arc welding, gas welding, and resistance welding. Each method offers unique benefits for different materials and applications.

Welding is a crucial process in many industries. It joins materials, usually metals, by melting and fusing them. This process creates strong bonds that are essential for construction, manufacturing, and repairs. Understanding welding classifications helps in selecting the right method for each job.Importance Of Welding

Welding is vital for building infrastructure like bridges and buildings. It is also used in the automotive industry to make cars and trucks. Aircraft and ships rely on welding for their construction. Welding ensures the strength and durability of these structures. It is essential for safety and longevity.Overview Of Classification Systems

Welding processes are classified in various ways. One common method is by the type of energy source used. This includes electric arc, gas, laser, and resistance welding. Another system classifies based on the process, such as MIG, TIG, and stick welding. Each classification helps in understanding the equipment and techniques needed. Different jobs require different welding methods. Proper classification ensures the right method is used. “`

Credit: www.minaprem.com

Fusion Welding

Fusion welding joins materials by melting them together. This process includes methods like arc welding, gas welding, and laser welding. Each method relies on heat to fuse materials seamlessly.

Fusion welding is a process where heat melts the base materials. The molten materials then cool and solidify to form a strong joint. This method is widely used in various industries. It ensures durable and reliable connections. There are two main types of fusion welding: arc welding and gas welding.Arc Welding

Arc welding uses an electrical arc to create heat. The heat melts the metals at the welding point. An electrode delivers the current to form the arc. The process can be manual or automated. There are different types of arc welding. One common type is Shielded Metal Arc Welding (SMAW). Another is Gas Metal Arc Welding (GMAW), often known as MIG welding. Each type has its own advantages. Arc welding is popular for its strength and versatility. It is used in construction, automotive, and manufacturing industries.Gas Welding

Gas welding uses a flame to melt the metals. The flame comes from burning a fuel gas with oxygen. The most common type is Oxy-Acetylene welding. This method is simple and portable. It does not require electricity, making it useful in remote locations. Gas welding is great for thin materials. It is often used in automotive repair and plumbing. The process allows for precise control of the heat. This makes it suitable for delicate tasks. Gas welding is also useful for cutting and brazing metals. It is a versatile and essential technique in many fields. Fusion welding processes are fundamental in metalworking. They offer strong, reliable joints for various applications. Understanding the differences helps in choosing the right method.Solid-state Welding

Solid-state welding joins metals without melting them. Heat and pressure are applied to make the joint. This method keeps the materials’ original properties intact. It is useful for joining dissimilar metals. Let’s explore two types of solid-state welding.

Forge Welding

Forge welding is one of the oldest welding methods. Blacksmiths have used it for centuries. It involves heating the metals until they are soft. Then, they are hammered together. This creates a strong bond. Forge welding is still used for artistic metalwork. It is simple but effective.

Friction Welding

Friction welding uses mechanical friction to generate heat. The pieces are rubbed together under pressure. This causes the materials to fuse. No melting occurs in this process. Friction welding is fast and clean. It is often used in aerospace and automotive industries. It provides strong, reliable joints.

Resistance Welding

Resistance welding is a fascinating technique that uses pressure and electric current to join metal parts. Unlike other welding methods, it doesn’t require any filler materials. The process is efficient and often used in industries where speed and precision are vital. Let’s dive into two common types of resistance welding: Spot Welding and Seam Welding.

Spot Welding

Spot welding is like the quick fix of the welding world. It’s the go-to method for joining thin metal sheets. Imagine you have two pieces of metal, and you want to join them at specific points. Spot welding does exactly that. It creates small “spots” of weld at the exact locations you need.

Here’s a simple breakdown of the process:

- Two metal sheets are placed together.

- Electrodes press on the sheets and pass electric current through them.

- The heat generated melts the metal at the contact point.

- Pressure from the electrodes forms a weld spot.

Spot welding is commonly used in the automotive industry for assembling car bodies. It’s quick, efficient, and perfect for high-volume production. Have you ever looked at the door of a car and noticed small circular marks? That’s spot welding in action!

Seam Welding

Seam welding is a close cousin of spot welding but with a twist. Instead of creating individual spots, seam welding creates a continuous weld along a seam. Think of it like using a sewing machine, but for metal!

Here’s how it works:

- Metal sheets are placed together, just like in spot welding.

- Electrodes shaped like wheels roll over the sheets.

- As the wheels roll, they pass electric current through the metal.

- The continuous movement and current create a seam weld.

Seam welding is ideal for making gas-tight or liquid-tight joints. It’s often used in making fuel tanks, radiators, and even metal containers. The continuous weld ensures there are no gaps, providing a strong and leak-proof joint.

Both spot and seam welding are integral to modern manufacturing. They offer speed, efficiency, and precision. Whether you’re assembling cars or creating containers, resistance welding has got you covered. It’s an essential skill for any welder to master!

Energy Beam Welding

Energy Beam Welding is a fascinating area in the field of welding. It uses high-energy beams to join materials together. This technique is precise and powerful, allowing for excellent control and strong bonds. There are two main types of Energy Beam Welding: Laser Welding and Electron Beam Welding. Let’s explore them!

Laser Welding

Laser Welding is like using a high-tech flashlight to join metal pieces. A laser beam, which is a concentrated light, melts the materials and fuses them together. Here are some key points about Laser Welding:

- Precision: The laser beam is very accurate, making it great for small parts.

- Speed: It’s fast, reducing welding time.

- Heat Control: Less heat spreads to the rest of the material, reducing damage.

Imagine you’re using a magnifying glass to focus sunlight and burn a hole in a paper. Laser Welding works in a similar way, but much more powerful and controlled. It’s commonly used in the automotive and aerospace industries.

Electron Beam Welding

Electron Beam Welding uses electrons to create a weld. It sounds like science fiction, but it’s very real and effective. Here’s what makes Electron Beam Welding special:

- Deep Penetration: The electron beam can weld thick materials.

- Vacuum Environment: It requires a vacuum, which helps prevent contamination.

- Strength: The welds are very strong and durable.

Think of it like a super-powered electron gun that melts metal with pinpoint accuracy. It’s mostly used in industries that need very strong welds, like shipbuilding and heavy machinery.

Both Laser Welding and Electron Beam Welding offer unique advantages. They are advanced techniques that make modern manufacturing possible. Next time you see a car or a plane, remember that these high-tech welding methods helped build them!

Specialized Welding Techniques

Specialized welding techniques offer unique solutions for joining materials in challenging environments. These methods are essential for specific applications where traditional welding falls short. They ensure strong, reliable bonds, often without the need for additional fasteners. Let’s explore some of these advanced techniques.

Ultrasonic Welding

Ultrasonic welding uses high-frequency vibrations to join materials. The process generates heat through the friction of the materials. This heat melts the materials, creating a bond when they cool. It is fast and efficient. Ultrasonic welding is commonly used for plastics and thin metals. It is ideal for electronic components and medical devices. This method does not require external heat sources.

Explosion Welding

Explosion welding uses controlled explosions to join two metals. The force of the explosion creates a high-pressure impact. This impact causes the metals to bond at the atomic level. Explosion welding is useful for joining dissimilar metals. It is often used in the aerospace and defense industries. The process ensures a strong, durable bond. Explosion welding is also called explosive cladding.

Factors Influencing Welding Choice

Choosing the right welding process can feel like navigating a maze. There are so many factors to consider, and each one can significantly impact the final outcome. Whether you are welding for the first time or you are a seasoned professional, understanding these factors is crucial. Let’s dive into some of the key elements that can influence your welding choices.

Material Type

The type of material you are working with is probably the most important factor. Different materials require different welding methods. For example:

- Steel: Usually welded with MIG or TIG processes.

- Aluminum: Prefers TIG welding due to its need for precise control.

- Stainless Steel: Often welded with MIG or TIG, but the choice depends on thickness.

Each material has its quirks. Steel is strong, but it can warp if not handled correctly. Aluminum is lightweight but can be tricky due to its high conductivity. Stainless steel is resistant to rust, but it can be a pain to weld if it’s too thick or too thin. Understanding these nuances can save you a lot of headaches!

Welding Position

Believe it or not, the position of your weld can make or break the job. The position affects how the molten metal behaves, and it can be a challenge to control. Here’s a quick rundown:

- Flat Position: Easiest and most common. Gravity helps the weld pool.

- Horizontal Position: A bit trickier. Gravity works against you, making it harder to control the weld pool.

- Vertical Position: More challenging. You often have to weld upwards, which can be tough.

- Overhead Position: The most difficult. Gravity is your enemy, and you need to be very skilled to manage the weld pool.

Imagine trying to keep honey on a spoon while tilting it. That’s what welding in different positions can feel like. Flat is like holding the spoon level; it’s straightforward. But once you start tilting, things get tricky. Horizontal might feel like a 45-degree angle, vertical like 90 degrees, and overhead—well, that’s like trying to keep honey on an upside-down spoon!

So, when choosing your welding process, think about the material and the position. These two factors will guide you toward the right method, ensuring a strong, quality weld. Happy welding!

Credit: www.researchgate.net

Safety Considerations

When it comes to welding, safety is paramount. You can’t afford to cut corners because the risks are too high. From flying sparks to intense heat, welding can be hazardous. So, let’s dive into some crucial safety considerations that every welder should keep in mind.

Protective Gear

First things first, let’s talk about protective gear. It’s not just about looking cool in a welding helmet! Safety gear is your best friend on the job.

- Welding Helmet: This shields your face from sparks and harmful UV light. A good helmet can prevent eye damage and burns.

- Gloves: You need sturdy, heat-resistant gloves. They protect your hands from burns and cuts.

- Apron or Jacket: Wear a flame-resistant apron or jacket. This keeps your clothes from catching fire.

- Boots: Don’t forget your feet! Wear steel-toed boots to protect against falling objects.

Imagine forgetting your gloves one day. Ouch! Your hands would not appreciate it. Always double-check your gear before starting any welding work.

Workplace Safety

Next up, let’s talk about workplace safety. A tidy workspace is a safe workspace. Here are some tips to keep things in order:

- Clear the Area: Make sure your work area is free of clutter. Tripping over tools while holding a hot torch? No thanks!

- Ventilation: Welding produces fumes. Ensure good ventilation to avoid inhaling harmful gases.

- Fire Safety: Keep a fire extinguisher nearby. Also, remove any flammable materials from your work area.

- Proper Lighting: Good lighting helps you see what you’re doing, reducing the chance of mistakes.

Picture this: you’re welding away, and suddenly, you can’t see because your light is too dim. Not good. Proper lighting not only helps you work better but also keeps you safe.

By paying attention to these safety considerations, you can weld with confidence and avoid unnecessary accidents. So, gear up and stay safe!

Future Trends In Welding

Welding has come a long way from the days of fire and forge. Today, the welding industry is undergoing rapid changes, driven by technological advancements and new materials. But what does the future hold for welding? Let’s explore some exciting trends shaping the future of this essential craft.

Automation In Welding

Automation is taking the welding world by storm. Imagine robots doing the heavy lifting, literally. Robots can work tirelessly, ensuring each weld is perfect. This isn’t just science fiction; it’s happening now. For example, robotic welding arms are becoming common in factories. They bring precision, speed, and consistency to welding tasks, reducing human error and increasing efficiency.

Here are a few key benefits of automation in welding:

- Increased Productivity: Robots don’t need breaks or sleep. They can work round the clock, significantly boosting output.

- Improved Safety: Welding can be dangerous. Automated systems keep humans out of harm’s way.

- Consistency and Quality: Robots perform the same task in the same way every time, ensuring high-quality welds.

Of course, robots won’t replace welders entirely. They will work alongside skilled professionals, handling repetitive or hazardous tasks. This collaboration will lead to safer and more efficient workplaces.

Advanced Materials

Welding isn’t just about joining metals anymore. Today, we have advanced materials that offer unique properties. Materials like composites, alloys, and ceramics are changing the game.

But why are these materials important? Let’s break it down:

- Lightweight and Strong: New materials can be lighter and stronger than traditional metals. For example, carbon fiber composites are used in aerospace for their strength and low weight.

- Resistance to Corrosion: Some advanced materials resist corrosion better than metals, making them ideal for harsh environments.

- Heat Resistance: Materials like ceramics can withstand extreme temperatures, perfect for industries like aerospace and automotive.

Welders need to adapt to these new materials. Traditional welding techniques may not work, so learning new methods is essential. This means that ongoing education and training will be crucial for welders in the future.

So, the future of welding looks bright. Automation and advanced materials will create new opportunities and challenges. Are you ready to weld your way into the future?

Credit: www.weldingandndt.com

Frequently Asked Questions

What Is The Classification Of Welding Process?

The welding process is classified into fusion welding and solid-state welding. Fusion welding includes processes like arc welding and gas welding. Solid-state welding includes methods such as friction welding and ultrasonic welding.

How Can Welding Be Classified?

Welding can be classified into fusion and solid-state processes. Fusion welding includes MIG, TIG, and arc welding. Solid-state welding includes friction and ultrasonic welding.

How Do You Classify Welds?

Welds are classified by type, position, and purpose. Types include butt, fillet, and groove welds. Positions are flat, horizontal, vertical, and overhead. Purposes include structural and non-structural welds.

What Category Does Welding Fall Under?

Welding falls under the category of fabrication and metalworking. It involves joining materials, usually metals or thermoplastics, together.

Conclusion

Understanding welding process classification is essential for any welding project. Different methods suit different needs. Knowing these helps in choosing the right process. Proper classification improves efficiency and safety. It also ensures stronger welds. Take time to learn each method.

This knowledge can make a big difference. So, study these processes well. It will benefit your welding tasks. Happy welding!