Welding plays a crucial role in our everyday lives. It connects metal parts, creating strong structures.

Welding is more than just a skill. It’s a backbone of many industries, from construction to transportation. Without it, modern infrastructure would crumble. Bridges, buildings, and cars rely on welding. It ensures safety and durability. Beyond that, welding also supports innovation.

It allows engineers to design and build advanced machinery. In healthcare, welding helps make medical devices. In aerospace, it aids in crafting reliable aircraft. This invisible craft shapes our world in numerous ways. Let’s dive deeper into how welding truly helps the world.

Introduction To Welding

Welding is a fundamental process in many industries. It helps build and repair structures. This includes bridges, buildings, and vehicles. Without welding, modern infrastructure would not exist.

Welding joins materials, usually metals, by melting them. Once melted, the materials cool and fuse together. This creates a strong bond that is often stronger than the original pieces.

What Is Welding?

Welding is a technique for joining materials. It involves heating and melting the materials. Welders use different tools and techniques to achieve this. The process often requires a heat source, like an electric arc.

Welders can join metals, plastics, and other materials. The goal is to create a strong, permanent bond. This bond can withstand stress and environmental factors.

Brief History Of Welding

Welding has a long history. It dates back thousands of years. Early blacksmiths used basic welding techniques. They heated and hammered metals to join them.

Modern welding began in the 19th century. Advances in electricity made it possible. The invention of the electric arc was a major milestone. This allowed for more precise and stronger welds.

Today, welding is essential in many fields. It continues to evolve with technology. New methods and materials are constantly being developed. This makes welding more efficient and versatile.

Credit: worldskills.org

Welding In Infrastructure

When we think about welding, images of sparks flying and metal being joined together often come to mind. But did you know that welding plays a crucial role in shaping the world around us? From the towering skyscrapers that define city skylines to the sturdy bridges that connect communities, welding is the unsung hero in the realm of infrastructure. Let’s dive into how welding helps in building these marvels of engineering.

Building Bridges

Bridges are more than just pathways over water or valleys; they are lifelines for communities. Welding is essential in their construction, ensuring each part is firmly connected. Imagine this: without welding, the Golden Gate Bridge in San Francisco might not exist!

Here’s why welding is vital in bridge construction:

- Strength and Durability: Welded joints are incredibly strong, ensuring the bridge can withstand heavy loads and harsh weather.

- Precision: Welding allows for precise connections, which is crucial for the stability of the structure.

- Flexibility: Different welding techniques are used for various materials, from steel to aluminum, adapting to the specific needs of each bridge.

Constructing Skyscrapers

Ever marveled at the dizzying heights of skyscrapers? These giants of the urban landscape owe their existence to the power of welding. Building a skyscraper is like assembling a giant jigsaw puzzle, where each piece must fit perfectly.

Here’s how welding makes skyscrapers possible:

- Structural Integrity: Welding creates robust joints that hold the building’s framework together. This is especially important for withstanding winds and earthquakes.

- Speed: Welders can quickly join sections of the building, speeding up construction without compromising safety.

- Innovation: Advances in welding technology allow architects to design more daring and creative structures.

In short, without welding, our modern cities would look very different. Those shining glass towers? They start with the humble weld.

So, next time you cross a bridge or look up at a skyscraper, remember the welders who made it all possible. They might not be in the spotlight, but their work is everywhere, holding the world together one weld at a time.

Welding In Transportation

Welding plays a crucial role in transportation. This process joins metal parts to build and repair vehicles. From cars to ships, welding is essential for safety and durability. Let’s explore how welding impacts different transportation sectors.

Automobile Manufacturing

Welding is vital in automobile manufacturing. It ensures the strength of a car’s frame. This process joins metal parts like the body and chassis. Skilled welders create strong, seamless joints. These joints make cars safer and more reliable. Automated welding robots also speed up production. They enhance precision and reduce errors. Welding keeps our roads filled with safe, durable vehicles.

Shipbuilding And Repair

Welding is critical in shipbuilding and repair. Large ships require strong, watertight joints. Welders join metal plates to form the ship’s hull. These welds must withstand harsh sea conditions. Welding is also used for repairing damaged ships. Skilled welders fix cracks and restore structural integrity. This ensures ships remain seaworthy and safe. Welding keeps our maritime industry afloat.

Credit: www.nexair.com

Welding In Energy Sector

Welding is everywhere, including the energy sector. It plays a huge role in keeping our lights on and our cars moving. Without welding, many energy projects would stop. This means no oil, no gas, and no renewable energy sources like wind or solar. Let’s explore how welding impacts the energy sector.

Oil And Gas Pipelines

Oil and gas are transported through long pipelines. These pipelines need to be very strong. Why? Because they carry heavy and sometimes dangerous materials. Welding helps make these pipes. The welded joints keep the pipelines safe and secure.

- Welding joins sections of the pipeline.

- It ensures no leaks.

- It withstands high pressure and temperature.

Without welding, pipelines would break. This would cause oil spills and gas leaks. Nobody wants that, right? So, welders are like the hidden heroes here. They make sure the pipelines are strong and last long.

Renewable Energy Projects

We all love clean energy. It’s good for the planet. But did you know welding helps make this possible? Renewable energy projects, like wind turbines and solar panels, need welding too.

- Wind Turbines: These giant fans need strong bases. Welding joins the parts together. This keeps the turbine standing tall and spinning.

- Solar Panels: Welding helps join the frames. This keeps the panels in place. They can then capture sunlight and turn it into energy.

So, next time you see a wind turbine or a solar panel, think about the welding that made it possible. It’s amazing how welding helps us get clean energy!

In conclusion, welding is vital in the energy sector. It keeps our oil and gas pipelines safe and makes renewable energy projects possible. Welders are essential workers, making sure our world runs smoothly and stays green. Isn’t that cool?

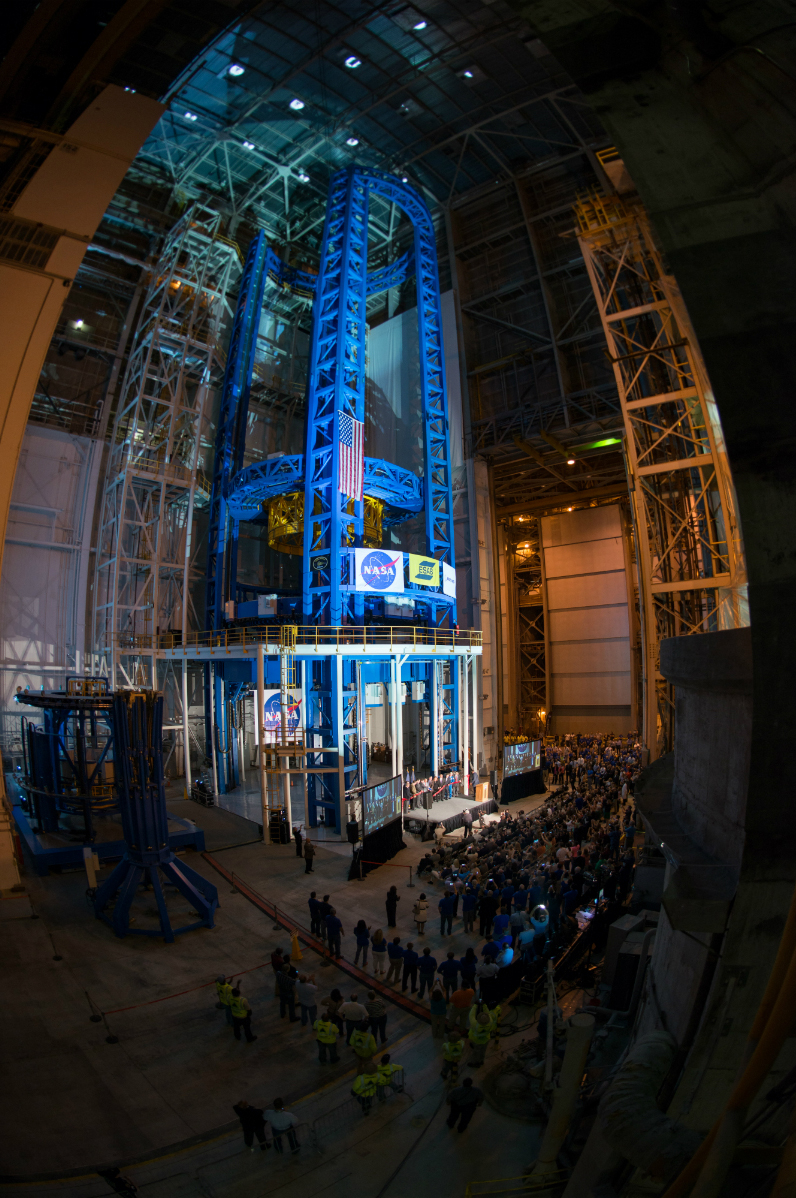

Welding In Aerospace

Welding plays a critical role in the aerospace industry. This technology ensures the creation of safe and reliable aircraft and spacecraft. Welding helps produce strong, durable joints essential for various aerospace applications. Let’s explore how welding impacts aircraft production and space exploration.

Aircraft Production

Welding is vital in aircraft production. It connects key components like the fuselage and wings. High precision is crucial in this field. Any mistake can compromise safety. Welders use advanced techniques to ensure perfect joints. The materials used in aircraft are often lightweight metals. Aluminum and titanium are common choices. These metals require specialized welding methods. The end result is a strong, lightweight aircraft. This ensures better fuel efficiency and performance.

Space Exploration

Welding is essential in the construction of spacecraft. Spacecraft face extreme conditions. They need to withstand high pressure and temperature changes. Welders use unique methods for this purpose. Electron beam welding is one such method. It provides high strength and precision. This ensures spacecraft can endure the harsh environment of space. Satellites, rockets, and space stations all rely on welding. The International Space Station, for example, has many welded parts. This ensures its structural integrity and longevity.

Advanced Welding Technologies

Advanced welding technologies are changing how we join materials today. They make welding faster, safer, and more accurate. These modern methods improve quality and reduce costs. Let’s explore some key technologies in this field.

Laser Welding

Laser welding uses a focused beam of light. This beam melts and joins materials. The method is highly precise. It can weld small and delicate parts. Laser welding is used in electronics and medical devices. This method works well with metals and plastics. It also causes less distortion.

Robotic Welding

Robotic welding involves automated machines. These robots perform welding tasks with high precision. They follow programmed instructions. This reduces human error. Robotic welding is common in the automotive industry. It speeds up production. It also improves safety. Workers are less exposed to harmful fumes and heat. Robots can work continuously. This increases efficiency and output.

Safety In Welding

Welding is an incredible skill that helps build everything from skyscrapers to cars. But, it can be dangerous if not done safely. So, how do welders stay safe? Let’s dive into the world of welding safety and see how professionals protect themselves.

Protective Gear

First up, protective gear. It’s like a knight wearing armor. Welders need to wear special clothes to stay safe. These include:

- Welding Helmet: This protects the face and eyes from bright light and sparks.

- Gloves: They protect hands from heat and sharp objects.

- Jacket: Made of leather, it shields the body from burns.

- Boots: Steel-toed boots keep feet safe from falling objects.

Without this gear, welding would be very dangerous. Just imagine getting a spark in your eye – ouch!

Safety Protocols

Gear is just the start. Welders also follow strict safety rules. These protocols keep everyone safe. Here are some important ones:

- Check Equipment: Always inspect tools before use. Faulty equipment can be hazardous.

- Ventilation: Ensure the area has good airflow. Welding fumes can be harmful.

- Fire Safety: Keep fire extinguishers nearby. Sparks can cause fires.

- Training: Continuous learning is key. Welders need to know the latest safety techniques.

Following these rules might seem like a lot, but it’s crucial. Think of it as a recipe for a delicious, safe-to-eat cake. Every step matters!

In conclusion, safety in welding is all about the right gear and following the rules. It ensures that welders can do their job without getting hurt. So, next time you see a welder, remember the armor they wear and the rules they follow. It’s not just about making things; it’s about making things safely.

Credit: www.space.com

Future Of Welding

The future of welding holds exciting possibilities. Advancements in technology and techniques are shaping the industry. Welding is becoming more efficient and sustainable. Let’s explore the innovations and sustainable practices in welding.

Innovations In Welding

Technology is transforming welding. Robotics and automation are leading this change. Robots can perform precise and consistent welds. They reduce human error and increase safety. Advanced welding machines use AI for better control. AI helps in monitoring and adjusting the welding process.

Laser welding is gaining popularity. It offers high precision and speed. Laser welds are strong and clean. 3D printing is also impacting welding. It allows for complex designs and reduces material waste. These innovations are making welding more advanced and efficient.

Sustainable Welding Practices

Sustainability is crucial in welding. New methods are reducing the environmental impact. Energy-efficient welding machines consume less power. This helps in lowering carbon emissions. Using recycled materials in welding is becoming common. It conserves resources and reduces waste.

Fumes and gases from welding can harm the environment. Advanced filtration systems are minimizing these emissions. Some welding processes use less harmful materials. This makes welding safer for workers and the planet. Sustainable practices are essential for the future of welding.

Frequently Asked Questions

Why Is Welding Important To The World?

Welding is crucial for building infrastructure, manufacturing vehicles, and constructing machinery. It ensures strong, durable, and safe joints.

How Does Welding Contribute To Society?

Welding strengthens infrastructure, enabling the construction of buildings, bridges, and vehicles. It supports manufacturing, boosts the economy, and creates jobs.

How Did Welding Change The World?

Welding revolutionized manufacturing and construction. It enabled stronger, more durable structures and advanced technology. The process significantly boosted industrial productivity and innovation.

How Does Welding Help The Environment?

Welding helps the environment by reducing waste through repair and recycling. It conserves resources and minimizes landfill use. Welding also lowers the carbon footprint by extending the lifespan of metal products, reducing the need for new materials.

Conclusion

Welding plays a crucial role in building our world. It ensures strong, reliable structures. Our bridges, cars, and homes depend on it. Skilled welders create lasting, safe connections. This craft supports many industries, boosting our economy. It’s clear: welding helps make our daily lives better.

It builds, repairs, and maintains the world we live in. Investing in welding means investing in a stronger, safer future. Welding truly makes a difference.