Fillet welds are incredibly common in many industries, from construction to automotive manufacturing. They provide strong and reliable joints when used correctly, but their strength is often misunderstood or overlooked.

When I first learned about fillet welds, one of the most challenging aspects was understanding how to calculate their strength. Why is this important? Because knowing the strength of your weld ensures your project will be safe, efficient, and compliant with any applicable standards.

I will walk you through everything you need to know about calculating fillet weld strength. By the end, you’ll feel confident tackling these calculations yourself, whether you’re designing a project or verifying weld quality in the field.

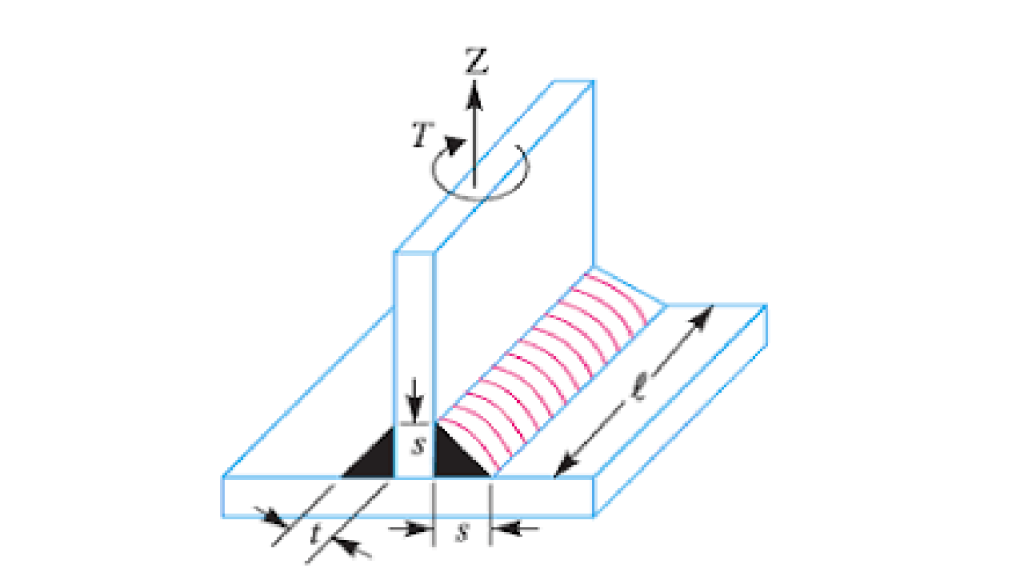

Image by uomus.edu.iq

Why Calculating Fillet Weld Strength Matters

Fillet welds are triangular joints used to fuse two pieces of metal. They may look small and simple, but they bear a significant amount of load. Calculating the strength of these welds is essential because:

- It helps prevent structural failures.

- It ensures the weld meets the required load capacity.

- It allows you to optimize material usage, avoiding over- or under-welding.

In practical terms, understanding weld strength gives you peace of mind that your design will hold up under pressure. Whether you’re a seasoned welder or new to the trade, it’s a skill worth mastering.

What Is Fillet Weld Strength?

Fillet weld strength is the load a weld can withstand before failure. This depends on several factors, including the size of the weld, the material being welded, and the type of forces applied (e.g., tension, shear).

The strength of a fillet weld is usually calculated based on its throat thickness. The throat is the shortest distance from the weld root to the face, and it plays a critical role in determining the weld’s load-bearing capacity.

Factors That Affect Fillet Weld Strength

Weld Size

The size of the weld directly impacts its strength. Larger welds generally have a higher load capacity, but they must align with the base metal thickness to avoid creating stress points.

Material Properties

The strength of the base metal and filler material affects the overall weld strength. For example, high-strength steels require welds that can match their performance.

Load Direction

Fillet welds are strongest in shear loading. When subjected to tension or bending, the strength is slightly reduced.

Weld Quality

Poorly executed welds with defects like porosity, undercut, or incomplete fusion can significantly reduce strength.

Step-by-Step Guide to Calculating Fillet Weld Strength

Calculating the strength of a fillet weld involves some basic formulas and an understanding of weld geometry. Here’s how to do it step by step.

Step 1: Identify the Required Parameters

To calculate the strength, gather the following information:

- Leg Size (L): The length of the fillet weld leg (in inches or millimeters).

- Weld Length (W): The total length of the weld along the joint.

- Throat Thickness (T): Calculated as T=0.707×L

- Allowable Stress (F): The maximum stress the material can handle (given in psi or MPa).

Step 2: Calculate the Throat Area

The throat area is the effective cross-sectional area of the weld that resists the applied load. Use the formula:

Throat Area (A)=T×W

Where:

- TTT is the throat thickness.

- WWW is the weld length.

Step 3: Determine the Load Capacity

The load capacity of the weld can be calculated by multiplying the throat area by the allowable stress:

Load Capacity (P)=A×F

Where:

- AAA is the throat area.

- FFF is the allowable stress for the weld material.

For example, if the throat area is 0.5 square inches and the allowable stress is 20,000 psi, the load capacity would be:

P=0.5×20,000=10,000 lbs

Step 4: Adjust for Load Direction

If the weld is subjected to non-shear forces, apply a strength reduction factor. For tensile or bending loads, reduce the calculated strength by about 30%.

Example Calculation

Let’s calculate the strength of a fillet weld:

- Leg Size (L): 0.25 inches

- Weld Length (W): 10 inches

- Allowable Stress (F): 18,000 psi

Calculate the throat thickness

T=0.707×0.25=0.17675inches

Determine the throat area

A=T×W=0.17675×10=1.7675 square inches

Calculate the load capacity

P=A×F=1.7675×18,000=31,815lbs

Common Mistakes to Avoid

Ignoring Throat Thickness

Many assume the leg size equals the weld strength, but the throat determines the actual load capacity.

Overlooking Load Direction

Always account for the type of load—shear, tension, or bending—when calculating weld strength.

Using Incorrect Material Properties

Ensure you’re using the correct allowable stress values for the material and weld type.

Not Considering Safety Factors

Always include a safety factor to account for unforeseen stresses or material inconsistencies.

Applications of Fillet Weld Strength Calculations

Understanding fillet weld strength is crucial in many industries. Here’s where you’ll see it most:

- Structural Engineering: Ensuring beams and columns can bear loads safely.

- Automotive Manufacturing: Designing welds that withstand vibrations and dynamic forces.

- Shipbuilding: Calculating welds that resist both shear and tensile loads in harsh environments.

- Pressure Vessels: Verifying welds can handle high pressures and temperatures.

Quick Reference for Fillet Weld Strength Calculations

| Parameter | Description | Formula |

|---|---|---|

| Leg Size (L) | Length of the weld leg | Given or measured |

| Throat Thickness (T) | Effective thickness of the weld | T=0.707×LT = 0.707 \times LT=0.707×L |

| Throat Area (A) | Load-bearing area of the weld | A=T×WA = T \times WA=T×W |

| Load Capacity (P) | Maximum load the weld can bear | P=A×FP = A \times FP=A×F |

Conclusion

Calculating fillet weld strength might seem intimidating at first, but with practice, it becomes second nature. By following these steps, you’ll ensure your welds are safe, efficient, and fit for purpose.

I’ve found that taking the time to calculate weld strength not only improves project quality but also gives me confidence in my work. Remember, it’s always better to double-check your math than to face a weld failure later on.

If you’re new to this, start with simple examples and work your way up. And don’t hesitate to consult a welding engineer or use reference guides if you’re unsure.

FAQs About Fillet Weld Strength

What is the throat thickness in a fillet weld?

Throat thickness is the shortest distance from the weld root to the face and determines the weld’s strength.

Why is the throat area important in weld calculations?

The throat area represents the effective load-bearing cross-section of the weld. It’s used to calculate the weld’s load capacity.

How does load direction affect fillet weld strength?

Fillet welds are strongest in shear. For tension or bending loads, a strength reduction factor is applied.

What is the role of allowable stress in weld calculations?

Allowable stress is the maximum stress the material can withstand. It’s used to determine the weld’s load capacity.

Can I use leg size instead of throat thickness for calculations?

No, leg size is not an accurate indicator of weld strength. Always use throat thickness for reliable calculations.

Endow Russel the owner chief editor of giftendow.com . I am a mechanical engineer and assign to an local firm with much experience in welding and industrial equipment.