Calculating welding rod consumption for pipe projects is essential. It helps plan resources and budget accurately.

Welding rods, or electrodes, are crucial for welding. Knowing how many rods you need can save time and money. Accurate calculations prevent running out of materials mid-project. It also stops overbuying, which wastes money. Whether you are a professional or a hobbyist, understanding welding rod consumption is vital.

In this guide, we will explain the steps to calculate welding rod usage. This will make your welding projects smoother and more efficient. Get ready to dive into the basics of welding rod consumption for pipes. Let’s ensure your next welding task is well-prepared and successful.

Credit: www.wsipl.com

Introduction To Welding Rod Consumption

When you start welding, one of the first things you need to understand is how to calculate welding rod consumption. This is especially important when working with pipes. Knowing how much welding rod you will need helps you plan better, avoid wastage, and save money. Plus, it ensures you have enough materials on hand, so you don’t run out in the middle of a job.

Importance Of Accurate Calculation

Why is it crucial to calculate welding rod consumption accurately? Well, for starters, it helps you budget your project. Imagine running out of welding rods halfway through a pipe welding project. It’s not just frustrating; it can delay your work and cost you more in the long run.

Accurate calculation also means you can order the right amount of materials upfront. This reduces the risk of having too many leftover rods, which might go to waste. Plus, you can avoid the hassle of making multiple trips to the supplier. Efficient project planning = happy welder!

Common Challenges

Now, let’s talk about the common challenges you might face when calculating welding rod consumption. One of the biggest hurdles is not accounting for wastage. Every welder knows that some rods break, some burn too quickly, and others just don’t weld right. Ignoring this can throw off your calculations.

Another challenge is estimating the weld length and thickness accurately. Pipes come in various sizes, and the weld requirements can vary significantly. Misjudging these can lead to either a shortage or excess of welding rods. And let’s not forget about the different types of welding rods and their consumption rates. Each type has its own characteristics and burn rates, adding another layer of complexity to your calculations.

Here’s a quick tip: Keep a log of your past projects. Record the length, diameter of the pipes, type of welding rod used, and how many you consumed. This data can be invaluable for future projects.

In conclusion, understanding and accurately calculating welding rod consumption can save you time, money, and a lot of frustration. It may seem daunting at first, but with a bit of practice and attention to detail, you’ll become a pro in no time. Happy welding!

Types Of Welding Rods

When it comes to welding pipes, the type of welding rod you use is crucial. Different welding rods have different characteristics that can affect the quality of the weld. Knowing the right rod to use for your specific project is key. Let’s dive into the various types of welding rods and how to choose the right one for pipe welding.

Overview Of Different Rod Types

Welding rods, also known as electrodes, come in various types, each with specific properties. Here’s a quick rundown:

- 6010: Known for deep penetration, excellent for dirty or rusty metal.

- 6011: Similar to 6010 but can be used with AC or DC welding machines.

- 6013: Ideal for beginners, produces a smooth and clean weld.

- 7018: Produces strong welds, resistant to cracking, and good for heavy-duty work.

Each rod has a unique composition that affects its performance. For example, 7018 rods contain iron powder which makes the weld stronger and smoother.

Selecting The Right Rod For Pipe Welding

Choosing the right welding rod for pipe welding can be a bit of a puzzle. But don’t worry, I’ve got some tips to make it easier!

- Material Type: First, consider the material of the pipe. Stainless steel, carbon steel, and cast iron pipes each require different rods.

- Position: Are you welding in a flat, horizontal, vertical, or overhead position? Some rods work better in specific positions.

- Thickness: The thickness of the pipe will determine the rod size. Thicker pipes need rods that can handle more heat and produce a stronger weld.

- Environment: Is the pipe clean or rusty? Some rods, like the 6010, are better for dirty environments.

For instance, if you’re welding a thick carbon steel pipe in a vertical position, a 7018 rod would be a great choice. It’s strong, versatile, and handles the heat well.

Remember, practice makes perfect. Try different rods on scrap material to see which works best for your project. Happy welding!

Factors Influencing Rod Consumption

Calculating welding rod consumption for pipe is essential. Various factors influence this calculation. These factors include pipe diameter, thickness, welding position, and technique. Understanding these factors helps in estimating the right amount of welding rods needed.

Pipe Diameter And Thickness

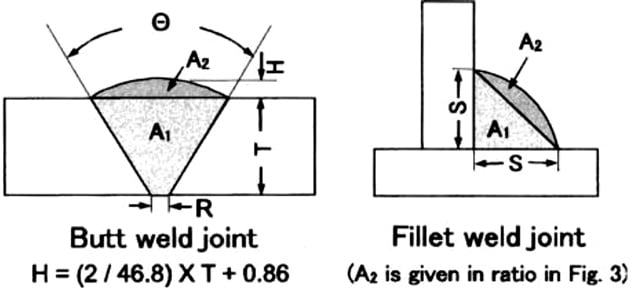

Pipe diameter impacts the amount of welding rod needed. Larger diameters require more weld material. Thickness also plays a role. Thicker pipes consume more rods. This is because thicker materials need more filler metal. It ensures a strong and durable weld. Always consider both diameter and thickness for accurate estimation.

Welding Position And Technique

Welding position affects rod consumption. Vertical and overhead positions use more rods. This is due to the difficulty and technique involved. Horizontal and flat positions are easier. They usually require fewer rods. The welding technique also matters. Techniques like TIG welding consume rods differently. Proper technique ensures efficient rod usage. Always factor in these elements for precise calculations.

Calculating Welding Rod Consumption

Calculating welding rod consumption is crucial for efficient project planning. Understanding the amount of welding rod needed can help save both time and money. This guide will walk you through the basic calculation formula and provide example calculations. By the end, you will know how to estimate the welding rod consumption for your pipe welding projects.

Basic Calculation Formula

The basic formula for calculating welding rod consumption is straightforward. You need to know the length of the weld and the diameter of the rod. Here is the formula:

Welding Rod Consumption (kg) = (Weld Length (m) x Weld Cross-Section Area (mm²)) / 1000

To find the weld cross-section area, use the following formula:

Weld Cross-Section Area (mm²) = π x (Rod Diameter (mm) / 2)²

Using these formulas, you can estimate the amount of welding rod required for your project.

Example Calculations

Let’s go through a couple of example calculations. Assume you have a weld length of 10 meters and a rod diameter of 4 mm.

First, calculate the weld cross-section area:

Weld Cross-Section Area = π x (4 mm / 2)²

Weld Cross-Section Area = π x (2 mm)²

Weld Cross-Section Area = π x 4 mm²

Next, use the basic formula to find the welding rod consumption:

Welding Rod Consumption = (10 m x 12.57 mm²) / 1000

In this example, you would need approximately 0.1257 kg of welding rod for a 10-meter weld using a 4 mm diameter rod.

Another example: Assume a weld length of 5 meters and a rod diameter of 6 mm.

First, calculate the weld cross-section area:

Weld Cross-Section Area = π x (6 mm / 2)²

Weld Cross-Section Area = π x (3 mm)²

Weld Cross-Section Area = π x 9 mm²

Next, use the basic formula to find the welding rod consumption:

Welding Rod Consumption = (5 m x 28.27 mm²) / 1000

For this example, you would need approximately 0.1414 kg of welding rod for a 5-meter weld using a 6 mm diameter rod.

Tips For Minimizing Rod Waste

Minimizing welding rod waste is crucial for cost-effective welding projects. Efficient welding practices and proper storage can significantly reduce waste. This guide provides practical tips to help you get the most out of your welding rods.

Efficient Welding Practices

Use the correct welding technique to avoid excessive rod consumption. Maintain a consistent welding speed. This prevents overheating and unnecessary rod use. Choose the right rod for the job. Different rods suit different materials and conditions.

Adjust the amperage settings on your welding machine correctly. Incorrect settings can lead to rod waste. Regularly clean your welding area. Dirt and debris can cause poor welds and wasted rods.

Proper Storage And Handling

Store welding rods in a dry, cool place. Moisture can damage the rods, leading to waste. Use airtight containers for storage. This prevents exposure to humidity and contaminants.

Handle rods carefully to avoid damage. Dropped rods can become unusable. Label rods clearly to avoid mix-ups. This ensures you use the right rod for the job.

Rotate your stock regularly. Use older rods first to prevent them from becoming obsolete. Inspect rods before use. Discard any damaged or corroded rods immediately.

Tools And Resources

Calculating the welding rod consumption for a pipe can feel like a daunting task, especially if you are new to welding. But don’t worry! With the right tools and resources, you can simplify the process and save yourself a lot of time and effort. In this section, we will discuss some essential tools and resources that can help you accurately calculate welding rod consumption for your pipe projects.

Using Welding Rod Calculators

One of the most convenient tools available for calculating welding rod consumption is the welding rod calculator. These calculators are designed to take the guesswork out of the equation. You simply input the dimensions of the pipe, the thickness of the material, and the type of weld you plan to use. The calculator does the rest!

Here are some steps to use a welding rod calculator:

- Input the pipe dimensions: Enter the diameter and length of the pipe.

- Specify material thickness: Provide the thickness of the pipe material.

- Select the welding process: Choose the type of weld (e.g., MIG, TIG, Stick).

- Calculate: Hit the calculate button to get the estimated rod consumption.

These calculators are available online and often come with user-friendly interfaces. Some even offer mobile app versions, making it easy to calculate on the go. Isn’t technology wonderful?

Reference Materials And Guides

In addition to calculators, having access to reliable reference materials and guides can be incredibly helpful. These resources provide detailed information on welding techniques, material properties, and best practices for efficient welding rod usage.

Here are a few types of reference materials you might find useful:

- Welding Handbooks: These comprehensive books cover various aspects of welding, including rod selection and consumption rates.

- Manufacturer Guides: Many welding rod manufacturers provide guides that include consumption charts and recommendations for different types of welds.

- Online Tutorials: Websites and video platforms offer tutorials that can help you understand the nuances of welding rod consumption.

Imagine having a seasoned welder by your side, sharing their wisdom and tips. That’s what good reference materials feel like. They can be a game-changer, especially when tackling complex projects.

By leveraging these tools and resources, you can ensure that your welding projects are efficient and cost-effective. So, next time you find yourself scratching your head over welding rod consumption, remember that help is just a few clicks away!

Common Mistakes To Avoid

Calculating the right amount of welding rod for a pipe can be tricky. It’s easy to make mistakes, especially if you don’t have much experience. But don’t worry! Here are some common mistakes to avoid when figuring out your welding rod needs.

Overestimating Rod Needs

One common mistake is overestimating how many rods you need. It’s easy to think that more is better. But buying too many rods can be a waste of money. Here’s a simple tip: measure twice, buy once.

Let’s break it down:

- Measure the pipe’s length and diameter.

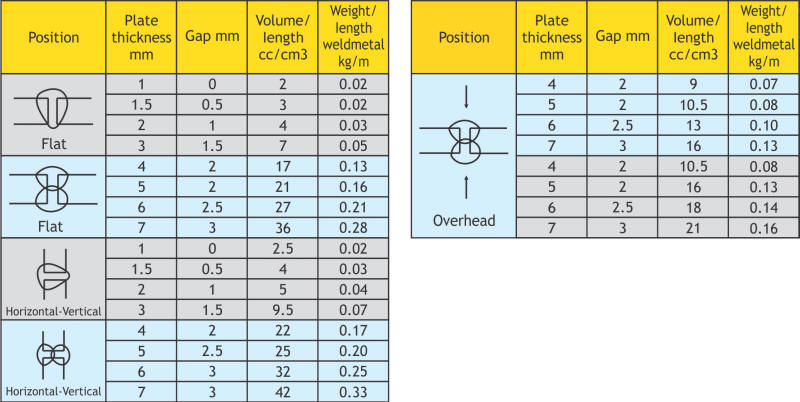

- Use a rod consumption chart. These charts help you see how many rods you need for a specific pipe size.

- Consider the welding technique. Some methods need more rods than others.

By following these steps, you avoid buying too many welding rods. This saves you money and reduces waste.

Ignoring Environmental Factors

Another mistake is ignoring the environment where you weld. Temperature, humidity, and wind can affect your welding. Here’s how:

- Temperature: Cold weather can make rods brittle. You might need more rods if they break often.

- Humidity: Moisture can cause rods to rust. Rusty rods don’t work well.

- Wind: Wind can blow away the shielding gas. This means more rod use to get a good weld.

Think about where you’ll be welding. Adjust your rod calculation to account for these factors. This ensures you have the right amount of rods.

Avoiding these common mistakes helps you calculate welding rod consumption more accurately. Remember, measure carefully and think about your environment. Happy welding!

Credit: weldingengineers.co.nz

Expert Advice

Calculating welding rod consumption for pipes can seem tricky. But with expert advice, you can make the process easier and more accurate. Here, we share insights from professional welders and advanced techniques for precision.

Insights From Professional Welders

Professional welders stress the importance of preparation. Always clean the pipes before welding. Dirt and rust can affect rod consumption. They also recommend measuring the pipe diameter accurately. Use a caliper for best results. This ensures your calculations are precise.

Another tip is to keep a welding log. Record the amount of rod used for each project. Over time, this helps predict future consumption. Experienced welders often rely on these logs. It saves time and improves accuracy.

Advanced Techniques For Accuracy

Use welding calculators available online. These tools factor in pipe size and material. They provide a close estimate of rod consumption. Remember to input all variables correctly. Small errors can lead to big miscalculations.

Consider the welding position. Overhead welding uses more rods than flat welding. Adjust your calculations based on the position. Also, check the rod’s diameter. Thicker rods cover more area but require more heat. This can affect consumption rates.

Finally, practice consistent welding speed. Irregular speed increases rod usage. Aim for steady, smooth movements. This ensures even bead formation and efficient rod use.

Credit: www.youtube.com

Frequently Asked Questions

How To Calculate Welding Rod Consumption?

To calculate welding rod consumption, determine the weld length and multiply it by the rod’s consumption rate per unit length. Consider the weld size and type. Add a 10% margin for wastage.

What Is The Formula For Welding Calculation?

The welding calculation formula is P = (I x E) x 60 / (1000 x η). Here, P is power, I is current, E is voltage, and η is efficiency.

How To Calculate Welding In A Pipe?

To calculate welding in a pipe, measure the pipe’s circumference. Multiply this by the length of the weld. Consider weld type and thickness for accuracy.

What Is The Consumption Rate Of The Electrode?

The electrode consumption rate varies based on its type and application. Typically, it ranges from 2 to 4 kg per hour.

Conclusion

Calculating welding rod consumption for pipe projects is crucial. It ensures efficient use of materials. Follow these steps to estimate accurately. Measure pipe length, choose the right rod, and consider weld joints. Practice improves your calculations over time. This saves both time and cost.

Remember to always double-check your numbers. Your welding projects will run smoother with precise planning. Happy welding!