Using a welding rod is a key skill for anyone working with metal. It involves melting the rod to join pieces together.

Welding rods are crucial in creating strong, lasting bonds in metalwork. Whether you are a beginner or have some experience, understanding how to use a welding rod can enhance your projects. This guide will break down the steps to help you use welding rods effectively.

We will cover the basics and share tips to improve your welding technique. By the end, you will feel more confident in your ability to create solid welds, ensuring your metal pieces hold up under pressure. Let’s get started with the essentials of using a welding rod.

Credit: www.steelsupplylp.com

Choosing The Right Welding Rod

Choosing the right welding rod is crucial for a strong, quality weld. Different materials and projects require different rods. Understanding the types and factors can help you make the best choice.

Types Of Welding Rods

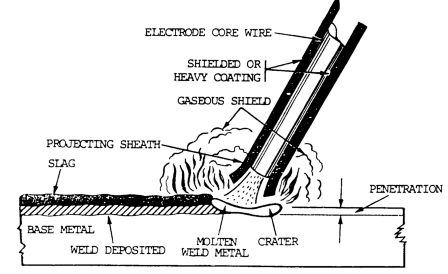

There are several types of welding rods available. The most common are consumable and non-consumable rods. Consumable rods melt and become part of the weld. Non-consumable rods do not melt. Instead, they create an arc to melt the metal.

Stick electrodes, also known as SMAW rods, are consumable. They are coated with flux to protect the weld. TIG rods, or GTAW rods, are non-consumable. These rods require a separate filler material. MIG wires are another type of consumable rod used in GMAW welding. They are fed through a welding gun.

Factors To Consider

Several factors affect your choice of welding rod. The first is the type of metal you will weld. Different rods work better with certain metals. For instance, mild steel rods are best for welding steel. Stainless steel rods are ideal for stainless steel projects.

Another factor is the welding position. Some rods work better for flat positions. Others are designed for vertical or overhead positions. The strength of the weld is also important. Some rods create stronger welds. Consider the environment where the welding will take place. Moisture and wind can affect the weld quality. Choose rods that perform well in these conditions.

Finally, consider the power source. Different rods require different power settings. Ensure your welding machine can handle the rod you choose. By considering these factors, you can select the right welding rod for your project.

Preparing For Welding

Welding is a skill that requires preparation. Preparing for welding helps ensure safety and quality. In this section, we will cover the important steps you need to take before welding. This includes choosing the right safety gear and setting up your workspace.

Safety Gear

Welding can be dangerous. Proper safety gear is essential. Wear a welding helmet to protect your eyes and face. Use gloves to shield your hands from heat. A long-sleeve shirt and pants protect your skin from sparks. Safety boots guard your feet. Do not forget ear protection. Welding can be loud, and earplugs or earmuffs help reduce noise.

Workspace Setup

A clean, organized workspace is important. Clear away any flammable materials. Ensure good ventilation to remove fumes. Position a welding table in the center of your area. Secure your workpiece to the table. Keep your tools within reach. Good lighting helps you see clearly. A fire extinguisher should be nearby for emergencies.

Setting Up The Welding Machine

Alright, folks! Before you can start welding, you must set up your welding machine correctly. It’s like preparing for a long journey—you need to ensure everything is in place. Let’s dive into the essentials of getting your machine ready for action.

Adjusting Settings

First things first, we need to adjust the settings on your welding machine. Think of this as tuning your guitar before a big concert. Each type of welding rod requires specific settings. Here’s a simple step-by-step guide:

- Power Source: Ensure your machine is connected to a reliable power source.

- Current Type: Choose between AC or DC based on your welding rod requirements. Most rods work well with DC.

- Amperage: Adjust the amperage according to the rod’s diameter. A rule of thumb is 1 amp per thousandth of an inch of rod diameter.

For example, if you’re using a 1/8 inch rod, set your machine to around 125 amps. Simple, right?

Connecting The Rod

Now that your settings are spot-on, it’s time to connect the welding rod. This step is like loading your brush before painting a masterpiece.

- Insert the Rod: Place the rod into the electrode holder. Ensure it’s secure but don’t squeeze too hard—think of it as holding a delicate flower.

- Connect the Ground Clamp: Attach the ground clamp to your workpiece. This ensures a stable arc and prevents any electrical mishaps.

- Check Connections: Double-check all connections. Loose connections can lead to weak welds or even sparks flying in unintended directions. Safety first!

And there you have it! Your welding machine is now set up and ready to make sparks fly, quite literally.

Remember, the devil is in the details. A well-prepared machine not only makes your job easier but also ensures your safety. Now, go forth and weld with confidence!

Proper Welding Techniques

Proper welding techniques ensure strong and durable welds. These techniques help welders create precise and clean joints. Mastering these methods boosts safety and efficiency.

Striking The Arc

Striking the arc is the first step in welding. Hold the welding rod at a slight angle. Gently tap the rod against the metal surface. This action creates an electrical circuit. A small spark will form. Quickly lift the rod to start the arc.

Keep your hand steady. If the rod sticks, pull it back quickly. Restart if needed. Practice makes this process smoother. Always wear protective gear.

Maintaining Arc Length

Maintaining arc length is crucial for a stable weld. Keep the rod tip close to the metal. The distance should be about the same as the rod’s diameter. Too close, and the rod may stick. Too far, and the arc may break.

Consistency is key. Move the rod at a steady pace. Watch the arc and adjust as needed. This ensures a uniform weld bead. Proper arc length reduces spatter and improves penetration.

Managing Heat And Speed

Managing heat and speed is crucial when using a welding rod. Proper control helps achieve strong and clean welds. It also prevents issues like burn-through or weak joints. Understanding how to manage heat input and adjust welding speed can greatly improve your welding results.

Controlling Heat Input

Controlling heat input is essential for a successful weld. Too much heat can cause the metal to melt excessively. This can lead to burn-through or warping. Too little heat results in weak welds. The key is to find the right balance.

Start by setting the correct amperage on your welding machine. Different metals require different settings. Thicker metals generally need more heat. Thinner metals need less. Consult your welding rod manufacturer’s guidelines for the best settings.

Maintain a steady hand and a consistent arc length. Keep the welding rod at the right angle. This helps control the heat and ensures even penetration. Practice on scrap metal to get a feel for the right heat input.

Adjusting Welding Speed

Adjusting welding speed is just as important as controlling heat. Welding too fast can cause shallow welds. Welding too slow can lead to excessive heat buildup. Both can weaken the weld.

Start by welding at a moderate speed. Watch the molten pool closely. It should move consistently along the weld path. If it lags, you are moving too fast. If it gets too large, slow down.

Practice different speeds on scrap metal. Find a speed that creates smooth and even welds. Adjust your speed based on the thickness of the metal. Thicker metals may require slower speeds for proper penetration.

Credit: blog.red-d-arc.com

Dealing With Common Issues

Welding can be tricky. Many face issues with welding rods. This section helps you deal with common problems. Learn how to fix them for better welds.

Porosity

Porosity means small holes in the weld. It happens when gas gets trapped. Dirty metal surfaces cause this. Clean the metal well before welding. Moisture in the rod or flux also causes porosity. Store rods in a dry place. Use a rod oven to keep rods dry. Check your shielding gas flow rate. Adjust it as needed. Weld in a clean, dry area. These steps help reduce porosity.

Cracks And Inclusions

Cracks weaken the weld. They form from rapid cooling. Preheat thick metals before welding. This slows cooling. Use the right rod for the metal type. Inclusions are trapped foreign materials. They weaken the weld too. Clean the base metal and rod. Remove any slag between passes. Use proper welding techniques. Avoid high welding speeds. Follow these tips to reduce cracks and inclusions.

Post-weld Procedures

Congratulations! You’ve finished your welding project. But wait, you’re not done yet. There are some important steps to take after welding to ensure your work is solid and lasting. These post-weld procedures can make the difference between a perfect weld and one that falls apart. Let’s dive into the crucial steps.

Cleaning The Weld

Once you’re done welding, the first thing you need to do is clean the weld. Why, you ask? Well, during welding, spatter, slag, and other impurities can cover the weld. If left unchecked, these can weaken the joint. Here’s a simple way to clean your weld:

- Remove the slag: Use a chipping hammer to knock off the slag. Be gentle yet firm.

- Brush it up: Take a wire brush and scrub the weld area. This will remove any remaining debris.

- Wipe it down: Use a clean cloth to wipe the weld. Make sure there’s no oil or dirt left.

It’s kind of like cleaning your room – a bit tedious, but very necessary.

Inspecting For Flaws

After cleaning, it’s time to inspect your weld. Think of this step as proofreading your work. You want to catch any mistakes before they cause problems. Here’s how to do it:

- Look for cracks: Small cracks can lead to big issues. Check the weld bead carefully.

- Check the fusion: Ensure the weld has properly fused with the base metal. A poor fusion can make the joint weak.

- Examine for porosity: Tiny holes or pores in the weld can compromise its strength. Make sure your weld is smooth and solid.

If you find any flaws, don’t worry. It happens to the best of us. Just grab your welding rod and fix the issues. Better now than later, right?

These post-weld procedures might seem like extra work, but they are essential. They ensure your weld is strong and durable. So, take the time to clean and inspect. Your hard work will pay off in the end!

Credit: www.millerwelds.com

Maintenance Of Welding Equipment

Maintaining your welding equipment is crucial for ensuring a smooth and safe welding experience. Proper care not only extends the life of your tools but also helps to produce high-quality welds. Let’s dive into some essential practices for keeping your welding gear in top-notch condition.

Storing Welding Rods

Welding rods, also known as electrodes, need special attention when it comes to storage. Improper storage can lead to moisture absorption, which can ruin the rods. Here are some tips:

- Keep them dry: Store welding rods in a dry, cool place. Use sealed containers or electrode ovens to prevent moisture.

- Avoid temperature fluctuations: Sudden changes in temperature can cause condensation. Keep the storage area at a consistent temperature.

- Rotate stock: Use the oldest rods first to ensure none go to waste.

Remember, a well-stored rod is a happy rod. And a happy rod means a clean, strong weld.

Regular Equipment Checks

Regular inspections of your welding equipment can save you from unexpected breakdowns. Here’s what to keep an eye on:

- Inspect cables and connections: Look for any signs of wear or damage. Replace worn-out cables immediately to avoid poor conductivity.

- Check the welding machine: Ensure the machine is functioning properly. Clean the vents to prevent overheating.

- Examine the torch: Check for gas leaks and ensure the nozzle is clean. A clean torch ensures a stable arc.

A stitch in time saves nine, as the old saying goes. Regular checks can prevent small issues from becoming big headaches down the road.

In conclusion, proper maintenance of welding equipment is key to achieving the best results in your welding projects. By storing your welding rods correctly and performing regular equipment checks, you’ll be well on your way to creating strong, reliable welds.

Frequently Asked Questions

How Are Welding Rods Used?

Welding rods are used in arc welding to join metal pieces. They create the weld pool and provide filler material. The rod melts under heat, bonding the metals together.

What Welding Rod Should A Beginner Use?

A beginner should use the E6013 welding rod. It’s easy to strike and provides smooth, stable arcs. Ideal for general purpose welding.

How Do You Use A Rod Welder?

To use a rod welder, first, wear protective gear. Connect the ground clamp to the workpiece. Select the correct electrode. Strike the arc, then move the electrode steadily along the joint. Adjust the speed and angle for a consistent weld.

Let it cool before inspecting.

Do You Push Or Pull A 7018 Welding Rod?

You should pull a 7018 welding rod. This technique ensures better penetration and minimizes slag inclusion for optimal weld quality.

Conclusion

Using welding rods can seem daunting at first. But with practice, it gets easier. Follow safety guidelines closely. Always wear protective gear. Keep your workspace clean and organized. Choose the right rod for your project. This ensures strong, durable welds.

Practice regularly to improve your skills. With time, you will become more confident. Happy welding!