If you’re new to welding or even if you’ve been at it for years, deciding between stringer bead and weave bead welding can sometimes feel confusing. I’ve been there, standing with the torch in hand, wondering which technique would give me the best results for my project.

The truth is, both methods have their strengths and applications, and knowing when to use each is key to mastering the craft.

Let’s dive into what makes stringer bead and weave bead welding unique, how they work, and which one might be the best fit for your needs.

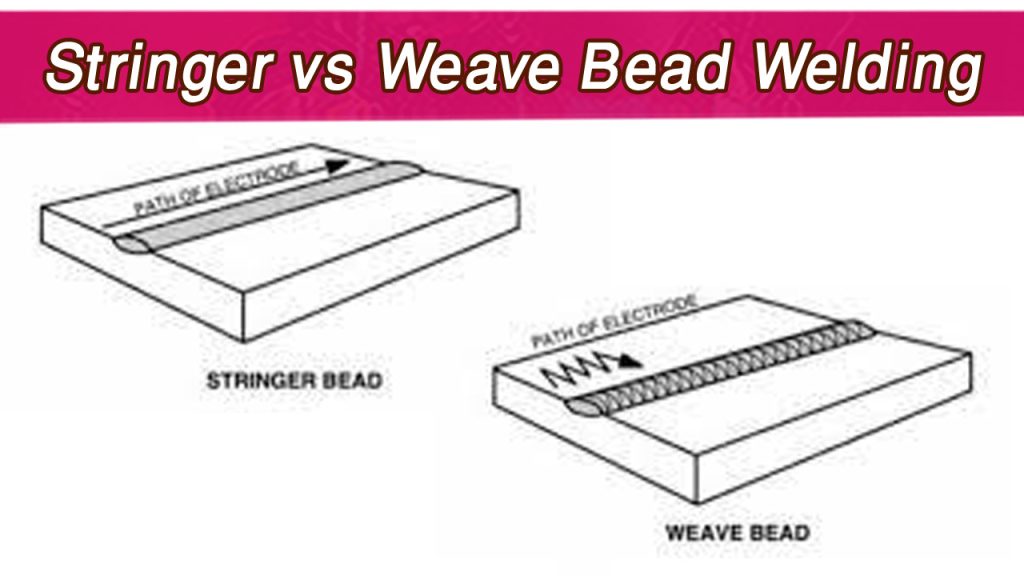

Image by auliaweldingschool

What is Stringer Bead Welding?

Stringer bead welding is all about creating a straight, narrow bead in a single pass. It’s clean, simple, and efficient. This method involves moving the welding electrode or torch in a straight line, keeping the motion tight and controlled.

Key Characteristics of Stringer Beads

- Narrow Bead Profile: Produces a slim weld bead.

- Fast Movement: Requires less lateral motion.

- Precision Focus: Ideal for areas that demand tight control.

Stringer beads are commonly used in situations where weld penetration is critical but time is limited. They work best for small weld joints and when welding in tight spaces.

What is Weave Bead Welding?

Weave bead welding, on the other hand, involves moving the electrode in a side-to-side motion. This creates a wider bead with more weld coverage. It’s a slower process compared to stringer bead welding, but the results are often more robust, especially in larger weld joints.

Key Characteristics of Weave Beads

- Wider Coverage: Creates a broader weld bead.

- Increased Deposition: Fills larger gaps effectively.

- More Heat Input: Requires careful control to avoid overheating.

This technique is often used for larger weld joints or in structural applications where extra reinforcement is needed.

Stringer Bead Welding: When and Why to Use It

I’ve found that stringer beads are my go-to choice when I need precision and speed. Here are some situations where stringer bead welding works best:

Applications

- Tight Spaces: Perfect for areas where larger movements are impractical.

- Vertical or Overhead Welds: Reduces the risk of slag dripping.

- Pipe Welding: Offers excellent penetration and control for pipe joints.

Advantages of Stringer Beads

- Cleaner welds with minimal spatter.

- Better penetration for deeper welds.

- Faster completion time compared to weave beads.

However, it’s worth noting that stringer bead welding might not be ideal for filling wider gaps or larger joints.

Weave Bead Welding: When and Why to Use It

Weave bead welding comes in handy when the project demands broader coverage or enhanced strength. I often rely on this technique when working on structural projects.

Applications

- Thicker Materials: Ideal for heavy-duty welding jobs.

- Wide Gaps: Easily fills larger spaces between joints.

- Multi-Pass Welds: Works well for layering welds on large surfaces.

Advantages of Weave Beads

- Distributes heat more evenly.

- Provides stronger reinforcement for joints.

- Suitable for large-scale applications like construction and fabrication.

Keep in mind that weave bead welding requires a steady hand to avoid overheating or warping the material.

Comparing Stringer and Weave Bead Welding

Let’s break down the key differences between these two techniques:

| Feature | Stringer Bead Welding | Weave Bead Welding |

|---|---|---|

| Bead Width | Narrow | Wide |

| Speed | Faster | Slower |

| Heat Input | Lower | Higher |

| Ideal For | Precision and penetration | Coverage and reinforcement |

| Ease of Use | Easier for beginners | Requires more skill and control |

Each technique serves a purpose, and choosing the right one depends on the project requirements.

How to Decide Which Welding Technique to Use

When I’m choosing between stringer and weave beads, I like to ask myself a few questions:

What is the size of the joint?

- For small joints, stringer beads are ideal.

- For larger gaps, weave beads work better.

How thick is the material?

- Thin materials benefit from stringer beads to prevent overheating.

- Thicker materials often require weave beads for stronger welds.

What is the position of the weld?

- Vertical or overhead positions are easier with stringer beads.

- Flat or horizontal positions suit weave beads well.

How much heat can the material handle?

Materials sensitive to heat do better with the lower heat input of stringer beads.

Tips for Mastering Both Techniques

Over the years, I’ve learned a few tricks that have helped me perfect both stringer and weave bead welding:

Stringer Beads:

- Keep your electrode steady and move in a straight line.

- Maintain a consistent travel speed to ensure uniform welds.

- Watch the weld pool closely to avoid undercutting.

Weave Beads:

- Practice your side-to-side motion to create even patterns.

- Use a slower travel speed to allow the bead to spread evenly.

- Be mindful of heat input to prevent material warping.

Common Mistakes to Avoid

We all make mistakes when we’re learning, and I’ve made my fair share. Here are some common pitfalls to watch out for:

Stringer Bead Mistakes:

- Traveling Too Fast: Can lead to incomplete penetration.

- Irregular Motion: Results in uneven welds.

Weave Bead Mistakes:

- Overlapping: Can weaken the weld.

- Excessive Heat Input: May cause distortion or burn-through.

Conclusion

Whether you’re working on a precise project or tackling a heavy-duty weld, knowing the difference between stringer and weave bead welding is crucial. Both techniques have their strengths, and understanding when to use each one will help you achieve the best results.

Personally, I’ve found that mastering both methods has opened up so many possibilities in my welding projects. It’s like having two powerful tools in your arsenal, ready to tackle any challenge.

FAQs

What is the main difference between stringer and weave bead welding?

Stringer bead welding produces narrow, precise welds, while weave bead welding creates wider, reinforced welds with more coverage.

Which technique is easier for beginners?

Stringer bead welding is generally easier for beginners due to its straightforward motion and faster speed.

Can I use weave bead welding on thin materials?

It’s possible, but weave beads can generate more heat, which might warp thinner materials.

What type of projects are best suited for stringer bead welding?

Stringer beads are ideal for pipe welding, tight spaces, and vertical or overhead welds.

How do I avoid overheating when using weave bead welding?

Use a steady motion, monitor your heat input, and adjust your travel speed to prevent overheating.

Endow Russel the owner chief editor of giftendow.com . I am a mechanical engineer and assign to an local firm with much experience in welding and industrial equipment.