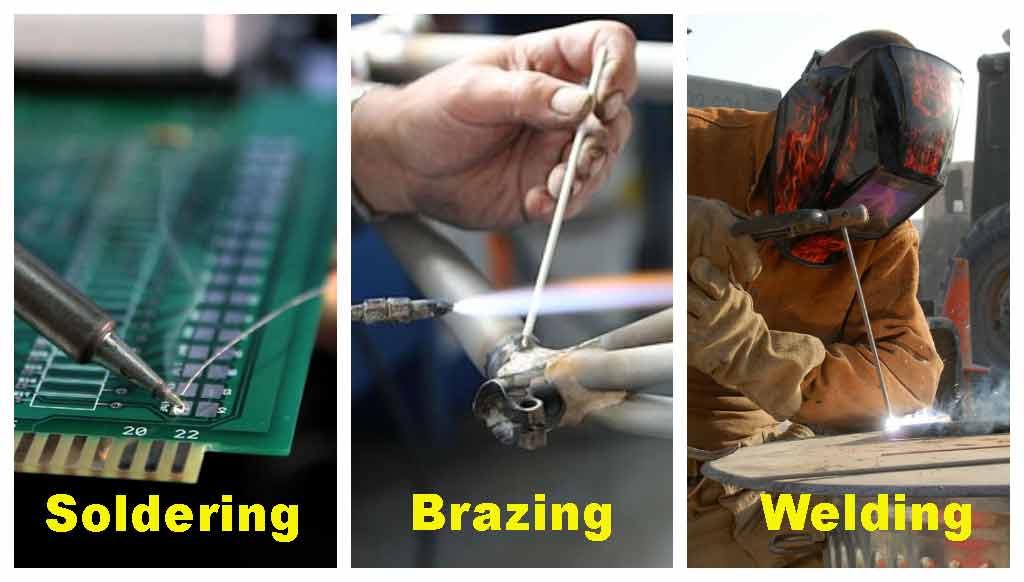

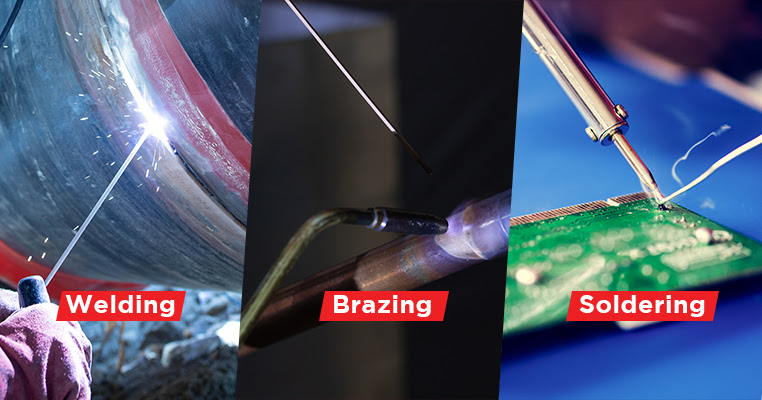

Understanding the differences between welding, soldering, and brazing is crucial. Each technique joins metals but serves different purposes and applications.

Welding, soldering, and brazing all involve metal joining. These methods are essential in various industries, from construction to electronics. Knowing when to use each process can save time and ensure stronger, more reliable joints. Welding involves melting the base metals, creating a strong bond.

Soldering uses a filler metal with a lower melting point, ideal for delicate tasks. Brazing, on the other hand, uses a filler metal with a melting point above soldering but below welding. Each method has unique benefits and limitations, making it important to understand their differences. This guide will help you decide which technique suits your needs best.

Credit: www.youtube.com

Welding Basics

Welding is a process that joins materials, usually metals or thermoplastics, by causing coalescence. It often requires a filler material to form a pool of molten material that cools to become a strong joint. Understanding the basics of welding is crucial for anyone involved in metalwork or construction.

Definition

Welding is the technique of joining two pieces of metal. This is done by melting the workpieces and adding a filler material. The filler material forms a pool of molten metal that solidifies into a strong joint. This process often requires heat and pressure.

Common Techniques

There are several common welding techniques. MIG welding uses a wire fed through a gun to create the weld. TIG welding uses a tungsten electrode to produce the weld. Stick welding uses a consumable electrode coated in flux. Each technique has its advantages and is suited to different applications.

Applications

Welding is used in many industries. It is common in construction, automotive repair, and shipbuilding. It is also used in the aerospace industry and in manufacturing. The versatility of welding makes it an essential skill in many fields.

Soldering Basics

Soldering is a technique used to join two or more metal items together by melting a filler metal, known as solder, into the joint. Unlike welding, soldering does not involve melting the workpieces themselves. This method is commonly used in electronics, plumbing, and jewelry making. Let’s dive into the essentials of soldering.

Definition

Soldering is a method of connecting metal parts by melting a filler metal into the joint. The filler metal has a lower melting point than the workpieces. This process is typically done at temperatures below 840°F (450°C). Soldering forms a strong, electrically conductive bond between metals, making it essential for electronic circuits and other delicate applications.

Common Techniques

There are several soldering techniques that one can use, depending on the project requirements:

- Hand Soldering: This is the most common method, where a soldering iron is used to melt the solder into the joint. It’s suitable for small-scale projects like fixing wires or assembling electronic components.

- Reflow Soldering: Often used in manufacturing, this technique involves applying solder paste to a circuit board, placing components, and then heating the assembly in an oven to melt the solder.

- Wave Soldering: This is another manufacturing method where a circuit board is passed over a wave of molten solder, ensuring all connections are soldered simultaneously.

Applications

Soldering finds its place in various industries and projects. Here are a few common applications:

| Industry | Application |

|---|---|

| Electronics | Connecting components on a circuit board |

| Plumbing | Joining copper pipes |

| Jewelry Making | Creating intricate designs and repairs |

Whether you’re repairing a broken wire on a vintage radio or assembling intricate jewelry, soldering is a versatile and reliable technique. It’s a skill that, once mastered, can save you time and money on repairs and allow you to create your own projects from scratch.

Ever tried soldering at home? It might seem daunting at first, but with a bit of practice, you’ll be surprised at how quickly you can pick it up. Remember, patience and a steady hand are key!

Brazing Basics

So, you’ve probably heard of welding and soldering, but have you heard of brazing? It’s a fascinating process that’s a bit like the middle child in a family. Often overlooked, but incredibly important. Brazing is a technique that joins metals without melting them. Instead, a filler metal is used. Curious to know more? Let’s dive into the basics of brazing.

Definition

Brazing is a metal-joining process. It involves heating a filler metal above 840°F (450°C). This filler metal flows into the joint between the base metals by capillary action. The key here is that the base metals do not melt. Instead, the filler metal bonds with the surface of the base metals, creating a strong joint.

Common Techniques

There are several techniques used in brazing. Here are a few common ones:

- Torch Brazing: Uses a gas flame to heat the metals. It’s versatile and widely used.

- Furnace Brazing: Involves heating in a furnace. This method is great for mass production.

- Induction Brazing: Uses electromagnetic fields. It’s quick and precise.

Applications

Brazing is used in many industries. Here are some common applications:

- HVAC Systems: Brazing is used to join pipes and tubes in heating, ventilation, and air conditioning systems.

- Automotive: It’s used to join various components in cars, such as fuel lines and radiators.

- Aerospace: Brazing ensures strong joints in aircraft parts, providing reliability and safety.

In conclusion, brazing is a fantastic metal-joining process. It’s versatile and widely used in various industries. Next time you see a sturdy joint in a machine, there’s a good chance brazing was involved. So, remember, while welding and soldering might get more attention, brazing is the unsung hero holding things together.

Key Differences

Understanding the key differences between welding, soldering, and brazing is crucial for anyone involved in metalworking. Each technique has unique applications and requirements. Let’s break down the main distinctions between these processes.

Temperature Requirements

Welding requires high temperatures, often above 3,000 degrees Fahrenheit. This heat melts the base metals. Soldering, on the other hand, uses much lower temperatures, typically below 840 degrees Fahrenheit. Brazing operates at a higher temperature than soldering but lower than welding, usually between 840 and 2,000 degrees Fahrenheit.

Filler Materials

Welding uses similar materials as the base metals. This ensures a strong bond. Soldering employs a filler metal with a lower melting point, like tin-lead alloy. Brazing also uses a filler metal, often a copper-zinc alloy, which melts above 840 degrees Fahrenheit.

Strength Of Joint

Welded joints are the strongest. They can withstand high stress and loads. Soldered joints are weaker, best for electrical connections and delicate tasks. Brazed joints offer moderate strength, suitable for plumbing and metalworking projects.

Advantages And Disadvantages

Understanding the advantages and disadvantages of welding, soldering, and brazing helps you choose the best technique for your needs. Each method has unique benefits and drawbacks. This guide breaks down these aspects to help you make an informed decision.

Welding

Welding creates strong, permanent joints. It works well for heavy-duty projects. The process involves melting the base metals and adding a filler. This creates a solid bond.

Advantages of welding include high strength and durability. Welded joints can handle high stress and pressure. They are also resistant to corrosion and wear.

Disadvantages of welding are the high heat required and the potential for distortion. It can also be expensive due to the need for specialized equipment and safety measures. Welding requires skilled operators to ensure quality.

Soldering

Soldering uses lower temperatures than welding. It melts a filler metal, called solder, to join parts. This technique is common in electronics and plumbing.

Advantages of soldering include less heat, reducing the risk of damage. The process is also easier to learn and requires less expensive equipment.

Disadvantages of soldering include lower joint strength. Soldered joints cannot handle high stress or pressure. They are also less resistant to corrosion and wear.

Brazing

Brazing involves joining metals using a filler metal with a higher melting point than solder. The base metals are not melted. Only the filler metal melts and flows into the joint.

Advantages of brazing include strong, leak-proof joints. The process can join dissimilar metals and complex shapes. It also requires less heat than welding, reducing the risk of distortion.

Disadvantages of brazing include lower joint strength compared to welding. Brazed joints are also less resistant to high temperatures. Proper cleaning and flux application are essential for strong bonds.

Credit: www.cruxweld.com

Safety Considerations

When comparing welding, soldering, and brazing, safety should be a top priority. Each method has unique risks and requires specific safety measures. Let’s dive into the safety considerations to ensure you’re well-prepared and protected while working with these techniques.

Protective Gear

Welding, soldering, and brazing all demand different protective gear to keep you safe. Here’s a quick rundown:

- Welding: You need a welding helmet to protect your eyes from the intense light. Wear flame-resistant gloves and a long-sleeved jacket to shield your skin from sparks. Don’t forget sturdy boots!

- Soldering: Safety glasses are a must to protect your eyes from splashes. Gloves can protect your hands from hot solder. Make sure you have proper ventilation or a fume extractor to avoid inhaling fumes.

- Brazing: Similar to welding, use safety goggles to protect your eyes. Gloves and long sleeves will protect your skin from heat and sparks. Adequate ventilation is crucial to avoid inhaling fumes.

Health Risks

Each technique carries potential health risks:

- Welding: Exposure to ultraviolet and infrared rays can harm your eyes and skin. Breathing in fumes from welding materials can cause lung damage over time.

- Soldering: Inhaling fumes, especially from lead-based solder, can lead to respiratory issues. Always work in a well-ventilated area.

- Brazing: Inhalation of fumes from fluxes and filler metals can be harmful. Skin burns from hot materials are also a risk.

Remember, health is wealth. Take these risks seriously and gear up accordingly.

Safe Practices

Adopting safe practices is key to avoiding accidents. Here are some tips for each technique:

- Welding: Always inspect your equipment before use. Keep flammable materials away from your work area. Work in a well-ventilated space to avoid fume buildup.

- Soldering: Never touch the tip of the soldering iron, as it gets extremely hot. Use a stand to hold the iron when not in use. Keep your work area clean and organized to avoid accidents.

- Brazing: Ensure your workspace is free of flammable items. Use a heat-resistant surface to work on. Always cool down your tools before storing them.

Pro tip: Always keep a first aid kit handy. Better safe than sorry, right?

In summary, whether you’re welding, soldering, or brazing, prioritizing safety will keep you out of harm’s way. Equip yourself with the right gear, be aware of health risks, and follow safe practices. Happy crafting!

Choosing The Right Technique

Choosing the right technique between welding, soldering, and brazing depends on several factors. Each method has its strengths and weaknesses. Understanding these can help you make the best choice for your project.

Project Requirements

The needs of your project dictate the technique to use. Welding is best for strong, permanent joints. It’s ideal for heavy-duty applications like construction. Soldering works well for delicate electronics. It creates connections without damaging sensitive parts. Brazing is good for joining different metals. It offers a strong bond without melting the base metals.

Material Considerations

Different materials require different techniques. Welding is perfect for similar metals like steel or aluminum. Soldering is suitable for small components and electronic parts. It uses a low melting point filler metal. Brazing can join dissimilar metals, like copper to steel. It uses a filler metal with a higher melting point than soldering.

Cost Implications

Cost is a crucial factor in choosing a technique. Welding equipment and materials can be expensive. It’s a good choice for large-scale projects. Soldering is cheaper, requiring less expensive tools and materials. It’s ideal for small-scale or hobby projects. Brazing costs lie between welding and soldering. It requires a moderate investment in tools and materials.

Credit: blog.red-d-arc.com

Frequently Asked Questions

What Is Stronger Welding Brazing Or Soldering?

Welding is stronger than brazing and soldering. Welding fuses materials together, creating a robust joint. Brazing and soldering use fillers, resulting in weaker bonds.

Is Solder As Strong As Welding?

No, solder is not as strong as welding. Soldering joins metals using a filler metal with a lower melting point. Welding fuses materials together, creating a much stronger bond.

Why Would You Braze Instead Of Weld?

Brazing allows for joining dissimilar metals. It requires lower temperatures, reducing metal distortion and preserving mechanical properties. The process is excellent for delicate assemblies and offers a clean, precise finish.

Why Would You Braze Instead Of Solder?

Brazing provides stronger joints suitable for high-stress applications. It also works better on dissimilar metals and higher temperatures.

Conclusion

Choosing the right method depends on the project. Welding, soldering, and brazing each have unique uses. Welding is great for strong, permanent joints. Soldering works well for electronics and delicate tasks. Brazing is ideal for joining different metals. Always consider material type and project needs.

Understanding these techniques ensures better, stronger results. So, assess your requirements and pick the suitable method. This way, you achieve the best outcome for your work.