Porosity in TIG welding is one of those challenges that every welder encounters at some point. It’s frustrating because it compromises the strength and appearance of your welds, and fixing it can take up valuable time. If you’re wondering why porosity happens and how to avoid it, you’re in the right place.

I’ve had my fair share of issues with porosity, and I can confidently say that understanding its causes is the first step to producing flawless welds.

We’ll explore what porosity is, why it occurs, and, more importantly, how you can prevent it. Whether you’re a seasoned welder or just starting out, this information will help you improve your welding quality and reduce those annoying pinholes and bubbles.

What is Porosity in TIG Welding?

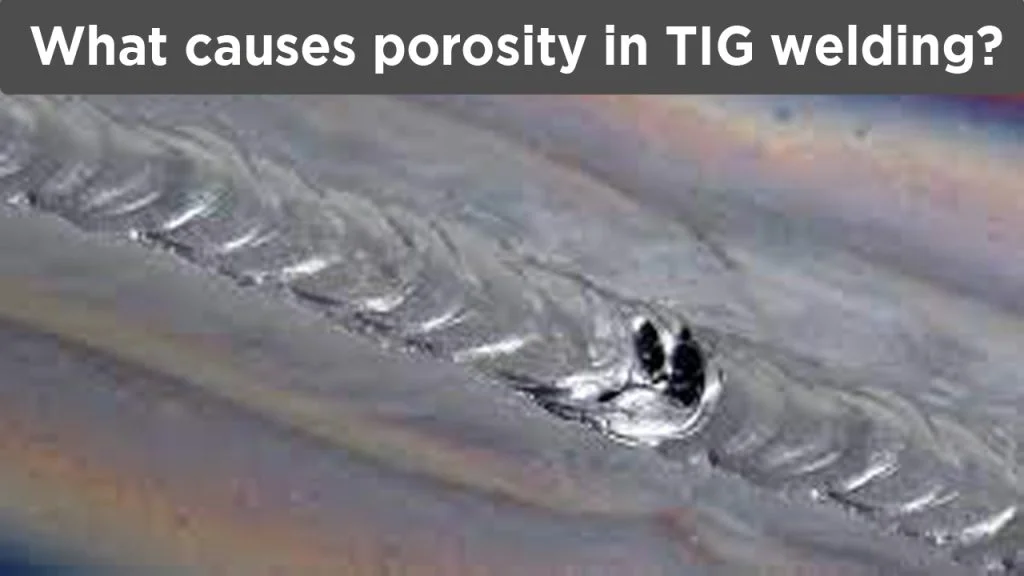

Porosity refers to small holes, voids, or pockets of trapped gas that appear in a weld. These imperfections often look like tiny bubbles in the weld bead or under the surface. Porosity weakens the weld, reduces its durability, and can lead to structural failures in critical applications.

It’s important to note that porosity isn’t always visible on the surface. Sometimes, it hides below the weld, which makes it even more dangerous for applications that demand strength and reliability. If you’ve ever experienced weld failure despite a good-looking surface, hidden porosity could be the culprit.

Types of Porosity in TIG Welding

Before diving into the causes, let’s take a quick look at the different types of porosity you might encounter:

- Surface Porosity: Visible holes or bubbles on the surface of the weld.

- Subsurface Porosity: Gas pockets trapped below the weld surface, often detected through X-rays or ultrasonic testing.

- Piping Porosity: Elongated voids that resemble tunnels running through the weld.

- Cluster Porosity: Groups of small bubbles concentrated in one area.

Each type has unique characteristics, but they all share a common origin—gas contamination during the welding process.

Causes of Porosity in TIG Welding

Porosity doesn’t just happen randomly; it’s usually the result of specific mistakes or unfavorable conditions. Here’s a breakdown of the most common causes and how they contribute to this frustrating issue:

Contaminated Base Metal

One of the biggest culprits of porosity is contamination on the base metal. Oils, grease, dirt, or even moisture can introduce unwanted gases into the weld pool. When these contaminants burn off during welding, they release gases that get trapped in the molten metal.

How to Avoid It

- Always clean the base metal thoroughly using a wire brush, solvent, or sandpaper.

- Make sure the surface is completely dry before you start welding.

Poor Shielding Gas Coverage

Shielding gas protects the molten weld pool from atmospheric contamination. If there’s insufficient gas coverage, oxygen, nitrogen, or hydrogen from the air can mix into the weld pool and cause porosity.

Common Reasons for Poor Coverage

- Incorrect gas flow rate (too low or too high).

- Faulty or damaged gas hoses.

- Wind or drafts blowing away the shielding gas.

- Improper torch angle leading to poor gas coverage.

How to Avoid It

- Use pure argon as your shielding gas for TIG welding.

- Set the gas flow rate between 15–25 cubic feet per hour (CFH) depending on the welding conditions.

- Inspect your hoses and fittings for leaks or damage.

- Avoid welding in windy environments, or use barriers to shield the weld area.

Incorrect Tungsten Preparation

Tungsten is the heart of TIG welding, and its preparation can directly impact weld quality. If the tungsten electrode is contaminated or not ground properly, it can introduce impurities into the weld.

How to Avoid It

- Always grind the tungsten to a sharp point using a dedicated tungsten grinder.

- Use clean, high-quality tungsten electrodes.

- Avoid touching the tungsten to the workpiece or filler rod during welding.

Improper Filler Material

Using the wrong filler rod or a contaminated one can also lead to porosity. Low-quality filler rods often contain impurities that release gases when melted.

How to Avoid It

- Use filler rods that match the material you’re welding.

- Store filler rods in a clean, dry place to prevent contamination.

- Wipe the rods with a clean cloth or solvent before use.

Moisture and Humidity

Moisture is another common cause of porosity. It can come from the environment, your base metal, or even the filler rod. When water evaporates during welding, it introduces hydrogen into the weld pool, which forms bubbles.

How to Avoid It

- Store materials in a dry environment to prevent moisture buildup.

- Preheat the base metal if you’re welding in a humid or cold setting.

- Keep your filler rods dry and sealed when not in use.

Excessive Heat Input

Overheating the weld pool can lead to porosity because it increases the likelihood of gas absorption and contamination. High heat also causes excessive oxidation, which can weaken the weld.

How to Avoid It

- Use appropriate amperage settings for the material and thickness.

- Practice consistent torch movement to avoid overheating one spot.

- Allow the weld pool to cool slightly if you notice excessive heat buildup.

Welding Technique Issues

Your welding technique plays a big role in preventing porosity. Improper torch angles, erratic movement, or inconsistent arc length can all contribute to gas entrapment.

How to Avoid It:

- Hold the torch at a consistent angle (around 15 degrees from vertical).

- Maintain a steady arc length of about 1/8 inch.

- Use smooth, deliberate movements to create an even weld bead.

Troubleshooting Porosity in TIG Welding

If you’re already dealing with porosity, don’t panic. Here’s a step-by-step guide to troubleshooting and fixing the issue:

- Inspect the Base Metal: Check for oil, dirt, or moisture and clean the surface thoroughly.

- Evaluate Gas Coverage: Ensure the gas flow rate is correct, and inspect hoses for leaks.

- Check Tungsten and Filler Rods: Replace contaminated tungsten or filler rods with clean ones.

- Adjust Heat Settings: Lower the amperage if you suspect excessive heat input.

- Refine Your Technique: Practice maintaining consistent torch angles and arc lengths.

Preventing Porosity: A Quick Checklist

| Cause | Prevention Tips |

|---|---|

| Contaminated base metal | Clean thoroughly with wire brushes and solvents. |

| Poor shielding gas | Use pure argon, correct flow rate, and protect from drafts. |

| Faulty tungsten | Grind tungsten properly and keep it clean. |

| Impure filler rods | Use high-quality rods and store them in a clean, dry area. |

| Moisture | Keep materials dry and preheat if necessary. |

| Excessive heat | Adjust amperage and avoid overheating the weld pool. |

| Technique issues | Maintain steady angles, arc lengths, and movement. |

Conclusion

Porosity in TIG welding might seem like an unavoidable annoyance at first, but once you understand its causes, you’ll realize it’s entirely preventable. By taking the time to clean your materials, ensure proper shielding gas coverage, and refine your technique, you can drastically reduce porosity and improve the quality of your welds.

Welding is as much an art as it is a science. Don’t be discouraged if you encounter porosity early on—it’s a learning opportunity. Practice, patience, and attention to detail will help you create strong, flawless welds every time.

FAQs

Can porosity weaken a weld?

Yes, porosity compromises the structural integrity of a weld and can lead to failures in high-stress applications.

How do I detect hidden porosity?

Hidden porosity can be detected using non-destructive testing methods like X-rays or ultrasonic testing.

What’s the best shielding gas for TIG welding?

Pure argon is the most commonly used shielding gas for TIG welding, especially for aluminum and steel.

Can weather affect porosity?

Yes, humid or windy conditions can introduce moisture or disrupt shielding gas, leading to porosity.

Why does my tungsten keep contaminating the weld?

Touching the tungsten to the filler rod or base metal can introduce contaminants. Keep the tungsten clean and maintain proper arc length.

By addressing these issues, you’ll be well on your way to producing welds that are strong, reliable, and free from porosity!

Endow Russel the owner chief editor of giftendow.com . I am a mechanical engineer and assign to an local firm with much experience in welding and industrial equipment.