When welding, getting the current right is crucial. Using too low a current can cause several issues.

Welding is a precise skill that requires attention to detail. One of the most important factors is the welding current. If the current is too low, it can lead to weak welds. This means the metal pieces may not join properly.

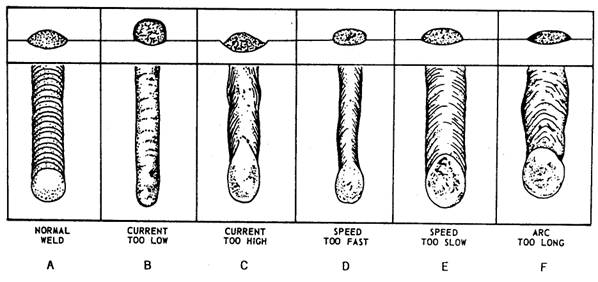

Low current can also cause poor penetration and an uneven weld bead. These problems can affect the strength and durability of the welded structure. Understanding the impact of low welding current can help you avoid these issues. This knowledge ensures you create strong, reliable welds every time. Let’s explore what happens when the welding current is too low and how to address it.

Credit: www.tpub.com

Importance Of Proper Welding Current

The importance of proper welding current cannot be overstated. It directly affects the quality and strength of the weld. Using the correct current ensures a strong bond between materials. On the other hand, incorrect current settings can lead to several issues.

Role Of Welding Current

Welding current plays a crucial role in the welding process. It determines the heat generated at the welding point. Proper current settings ensure adequate penetration and fusion of materials. The right current helps in forming a uniform and strong weld bead. It also minimizes defects like porosity and cracking.

Consequences Of Incorrect Current

Using too low a welding current can have adverse effects. One major consequence is poor penetration. The weld may not fuse properly with the base material. This can lead to weak joints and potential failures. Low current settings can also cause excessive spatter. This results in a messy and uneven weld.

Another issue is the formation of a convex weld bead. This occurs when the weld metal does not flatten out. It can weaken the overall strength of the weld. Low current can also lead to incomplete fusion. This happens when the weld does not fully bond with the base materials. Incomplete fusion can compromise the integrity of the welded structure.

Signs Of Low Welding Current

When welding, the correct current setting is crucial. Low welding current can cause various issues. Recognizing these signs helps you adjust and achieve a quality weld.

Visual Indicators

Low welding current produces several visual indicators. One clear sign is a narrow, ropey bead. This bead lacks proper fusion and appears uneven. Another sign is poor penetration. The weld does not go deep into the base metal. This weakens the joint and compromises strength. You might also notice excessive spatter. This makes the weld messy and requires more cleanup.

Performance Issues

Low welding current affects performance too. The arc becomes unstable and difficult to control. This leads to inconsistent welding and poor results. Another issue is difficulty in maintaining the arc. The arc may frequently extinguish, causing frustration and delays. Lastly, low current can cause incomplete fusion. This results in weak weld joints that can fail under stress.

Common Welding Defects

Using the right welding current is crucial. Too low a current can lead to several defects. These defects weaken the weld and can cause safety issues. Let’s explore some common defects that occur due to low welding current.

Porosity

Porosity happens when gas gets trapped in the weld. Low current can cause insufficient melting. This prevents proper gas release. As a result, tiny holes form in the weld. These holes weaken the structure. Porosity can also make the weld look unattractive.

Incomplete Fusion

Incomplete fusion occurs when the weld metal does not fully join with the base metal. Low current fails to provide enough heat. This leads to poor bonding. The weld may appear lumpy or uneven. This defect affects the strength of the weld. It can lead to failure under stress.

Impact On Weld Strength

Welding with the correct current ensures strong and durable joints. Using too low a current can significantly impact weld strength. This can lead to various issues that compromise the integrity of the welded structure. Let’s explore these impacts.

Reduced Structural Integrity

Low welding current can cause insufficient fusion between the metal pieces. This means the weld may not penetrate deeply enough, resulting in weak joints. Proper penetration is crucial for the strength and longevity of the weld. Without it, the welded structure loses its ability to bear loads effectively. This reduction in structural integrity can be dangerous, especially in critical applications.

Potential Failures

Welds made with low current are prone to various types of failures. These include cracking, porosity, and lack of fusion. Cracks can form as the weld cools and contracts, creating weak points. Porosity occurs when gas gets trapped in the weld, leading to holes that weaken the joint. Lack of fusion means the weld fails to bond with the base metal properly. These issues can cause the weld to fail under stress, leading to safety risks and costly repairs.

Effects On Weld Appearance

Welding with too low a current can have a significant impact on the appearance of your welds. When the current is not high enough, the weld doesn’t form correctly, leading to several noticeable issues. Below, we’ll dive into some of the common effects on weld appearance, focusing on Irregular Bead Shape and Poor Surface Finish.

Irregular Bead Shape

When the welding current is too low, the bead shape becomes irregular. Imagine trying to draw a straight line with a pen that’s running out of ink. The line gets blotchy and uneven, right? The same thing happens with welding.

- The weld bead may appear too narrow or too wide in places.

- You might see gaps or incomplete fusion.

- The bead might also look wavy and inconsistent.

These irregularities not only look unprofessional but can also lead to structural weaknesses. It’s like building a wall with uneven bricks; it just doesn’t hold up as well.

Poor Surface Finish

A low welding current can also result in a poor surface finish. Picture a rough, bumpy road compared to a smooth highway. Which one would you prefer driving on? The same goes for welds.

- The surface may be rough and uneven.

- You might see a lot of spatter and slag inclusions.

- The weld may lack the shiny, smooth finish that signifies a quality job.

This poor surface finish not only affects the appearance but also the weld’s durability. A rough surface can trap moisture and other contaminants, leading to rust and corrosion over time. Remember, a smooth weld is a strong weld.

In summary, using too low a welding current can turn what should be a seamless weld into a patchy mess. Keep an eye on that current setting, and you’ll be laying down beads like a pro in no time!

Troubleshooting Low Welding Current

Troubleshooting low welding current is crucial for achieving strong welds. Low current can lead to weak joints, poor penetration, and defects. It’s important to understand how to identify and correct this issue. This section will guide you through adjusting equipment settings and maintaining your welding tools.

Adjusting Equipment Settings

Ensure your machine is set to the correct amperage. Check the welding machine manual for recommended settings. Adjust the current dial to match the material and electrode used. Always start with the suggested settings and fine-tune as needed.

Inspect the connections between the welding machine and electrode holder. Loose connections can cause a drop in current. Tighten any loose connections and check for wear or damage. Replace worn parts to maintain proper current flow.

Ensure the ground clamp has a good connection. A poor ground can reduce the current. Clean the contact points and secure the clamp to the workpiece.

Proper Maintenance

Regular maintenance is key to preventing low welding current issues. Clean the welding machine and cables. Dust and debris can interfere with electrical connections.

Inspect the electrode holder and cables for damage. Replace any worn or frayed parts. Damaged cables can cause current loss and weak welds.

Check the power supply to the welding machine. Ensure it delivers consistent voltage. Fluctuations in power can affect the welding current.

Test the machine regularly to ensure it’s working correctly. Performing routine checks can catch potential issues early. This keeps your welding process smooth and efficient.

Preventative Measures

When welding current is too low, it can lead to various problems such as weak welds, excessive spatter, and poor penetration. To avoid these issues, it’s crucial to take specific preventative measures. Ensuring that your equipment is functioning correctly and that you have the right skills can make a significant difference. Let’s dive into the key steps you can take to prevent welding current issues.

Regular Calibration

One of the most effective ways to prevent welding current problems is through regular calibration of your welding machine. Just like your car needs regular maintenance, so does your welding equipment.

- Schedule periodic checks with a professional technician.

- Use a calibration tool to ensure your machine is set to the correct current.

- Document each calibration session for future reference.

Imagine trying to bake a cake without measuring the ingredients. The result could be a disaster! Similarly, without proper calibration, your welds can suffer.

Training And Best Practices

Even with the best equipment, improper technique can lead to problems. Investing in training and adhering to best practices is essential.

- Attend workshops or online courses to stay updated on welding techniques.

- Practice regularly to maintain and improve your skills.

- Follow safety guidelines to protect yourself and others.

Think of welding as an art form. Even Picasso started with the basics before creating masterpieces. By focusing on your training and following best practices, you can ensure that your welds are strong and reliable.

In conclusion, taking preventative measures such as regular calibration and proper training can help you avoid issues caused by low welding current. Not only will this ensure better weld quality, but it will also enhance your safety and efficiency. Remember, prevention is better than cure, especially when it comes to welding!

Credit: www.reddit.com

Case Studies And Examples

Understanding the impact of low welding current is crucial. It helps in preventing defects and ensuring safety. Let’s dive into some real-world case studies and examples.

Industry Incidents

In a large construction project, welders faced frequent joint failures. The team noticed weak welds that couldn’t support the structures. An investigation revealed the welding current was set too low. This resulted in poor penetration and weak bonds. The low current caused the filler material to not melt properly. Thus, the welds were not strong enough.

Another incident involved a pipeline repair. The welds failed pressure tests consistently. It was later found that the welding current was too low. This led to incomplete fusion between the pipe and the filler material. The pipeline had to be re-welded, costing time and money.

Successful Corrections

Adjusting the welding current fixed these issues. In the construction project, increasing the current improved weld penetration. The welds became strong and reliable. No more joint failures occurred. This simple adjustment saved the project from further delays.

In the pipeline repair case, technicians increased the welding current. They achieved better fusion and stronger welds. The pipeline passed all pressure tests. The project was completed on time and within budget. This highlights the importance of correct welding current settings.

Credit: www.reddit.com

Frequently Asked Questions

What Are The Effects Of Low Current In Welding?

Low current in welding leads to poor penetration, weak welds, and lack of fusion. It causes unstable arcs and excessive spatter.

What Is The Minimum Current For Welding?

The minimum current for welding varies by process. For stick welding, it’s typically around 40-60 amps. For MIG welding, it usually starts at 30-50 amps. Always refer to specific equipment guidelines for precise settings.

What Will Be The Result If The Amperage Is Set Too Low When Stick Welding?

Setting the amperage too low in stick welding results in poor arc stability. It leads to insufficient penetration and weak welds.

When The Welding Current Is Too Low, The Result Is Poor Fusion.?

Low welding current leads to poor fusion. This results in weak weld joints and potential structural failures. Ensure optimal current settings to achieve strong, durable welds.

Conclusion

Low welding current leads to weak welds. Poor penetration, incomplete fusion. These issues can cause structural failures. Safety risks increase significantly. Always monitor and adjust welding current. Ensure proper settings for best results. Quality welds depend on correct current. Avoid costly repairs.

Protect your work and reputation. Follow these tips for success. Happy welding!