Welded and seamless pipes are two common types in the piping industry. They differ mainly in how they are manufactured.

Understanding the differences between these two types of pipes is important. Welded pipes are made by welding pieces of metal together. Seamless pipes, on the other hand, are made from a single piece of metal without any seams. This fundamental difference affects their strength, usage, and cost.

In this blog post, we will explore the key differences between welded and seamless pipes. This will help you choose the right type for your specific needs. Stay with us as we delve into the details of each type, their manufacturing processes, and their applications.

Introduction To Pipes

Pipes play a crucial role in various industries. They are essential for transporting fluids, gases, and even solids. Whether in construction, manufacturing, or energy sectors, pipes are indispensable. Two main types of pipes are welded and seamless pipes. Each type has its own benefits and uses. Understanding these differences is important for choosing the right pipe for your needs.

Importance In Industry

Pipes are vital in many industrial applications. They help in the smooth flow of materials. Industries like oil and gas, water supply, and chemical processing rely heavily on pipes. Efficient piping systems ensure safety and productivity. They also help in maintaining the quality of transported materials. Choosing the right type of pipe can impact the overall efficiency of operations.

Common Applications

Welded pipes are often used in construction projects. They are ideal for transporting water and gas in buildings. Seamless pipes, on the other hand, are used in high-pressure applications. They are perfect for oil and gas exploration. These pipes can withstand extreme conditions. Both types of pipes are also used in automotive and aerospace industries. They ensure the safe and efficient flow of various materials.

Credit: www.bestarpipe.com

Welded Pipes

When it comes to pipes, understanding the difference between welded and seamless pipes is crucial. Each type has its unique properties, uses, and manufacturing processes. In this section, we’ll dive into welded pipes, exploring how they are made, their advantages, and disadvantages. Let’s get started!

Manufacturing Process

The manufacturing process for welded pipes is quite fascinating. It begins with a flat sheet of steel. This steel is rolled into a round shape and then welded along the seam. There are two common welding methods:

- Electric Resistance Welding (ERW): In this method, the edges of the steel are heated using electric resistance and then welded together.

- Longitudinal Submerged Arc Welding (LSAW): Here, the steel is submerged under a flux layer and welded using an arc.

Both methods ensure a strong bond, making the pipe durable and reliable. The welded seam may be visible, but modern techniques make it less noticeable and just as strong as the rest of the pipe.

Advantages

Welded pipes come with several benefits:

- Cost-Effective: They are generally cheaper to produce than seamless pipes, making them a more affordable option for many projects.

- Availability: Due to their simpler manufacturing process, welded pipes are widely available in various sizes and materials.

- Strength: The welding process enhances the strength of the seam, ensuring the pipe is robust enough for many applications.

These advantages make welded pipes a popular choice in industries like construction, plumbing, and gas transportation.

Disadvantages

However, welded pipes do have some downsides:

- Seam Vulnerability: The welded seam can be a weak point, potentially prone to corrosion over time.

- Less Suitable for High Pressure: For high-pressure applications, welded pipes might not be as reliable as seamless pipes.

- Surface Finish: The welding process can leave a visible seam, which might not be ideal for certain aesthetic or precision applications.

While these disadvantages exist, they don’t overshadow the practical benefits of welded pipes for many users.

In conclusion, welded pipes are a versatile and cost-effective option for various applications. Understanding their manufacturing process, advantages, and disadvantages helps in making an informed decision. Next, we’ll explore seamless pipes, so stay tuned!

Seamless Pipes

Seamless pipes are made from a solid piece of steel. Welded pipes are made by welding steel plates together. Seamless pipes have no joints or seams, while welded pipes have a visible seam.

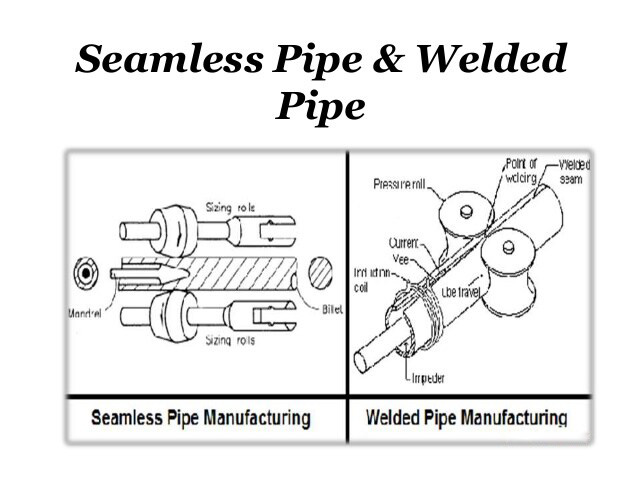

Seamless pipes are integral in many industries. They offer unmatched strength and reliability. The absence of seams makes them unique. Seamless pipes undergo a different manufacturing process than welded pipes. This process impacts their overall performance and usage.Manufacturing Process

Seamless pipes start as solid steel billets. These billets are heated and pierced to create a hollow tube. The tube is then stretched and rolled. This creates a seamless pipe. No welding is involved. This results in a uniform structure.Advantages

Seamless pipes have several benefits. They are strong and durable. They can withstand high pressure and temperature. Their uniform structure reduces the risk of leaks. They are ideal for critical applications. These include oil and gas industries.Disadvantages

Seamless pipes are more expensive. The manufacturing process is complex and costly. They are harder to find in specific sizes. Custom sizes might take longer to produce. This can lead to delays in projects. “`Material Considerations

When it comes to choosing between welded and seamless pipes, one of the most crucial factors to consider is the material used. The type of material can significantly affect the performance, durability, and cost of the pipes. In this section, we’ll delve into the different types of materials used in both welded and seamless pipes and how these materials impact their overall performance.

Types Of Materials Used

Both welded and seamless pipes can be made from a variety of materials. Here’s a breakdown of the most common ones:

| Material | Welded Pipe | Seamless Pipe |

|---|---|---|

| Carbon Steel | Yes | Yes |

| Stainless Steel | Yes | Yes |

| Alloy Steel | Yes | Yes |

| Copper | Yes | No |

| Aluminum | No | Yes |

Each material has its own set of advantages and disadvantages. For instance, stainless steel is highly resistant to corrosion, making it ideal for applications involving water or harsh environments. On the other hand, carbon steel is more affordable and offers good strength, making it a popular choice for general-purpose piping.

Impact On Performance

The material used in the pipes not only affects their cost but also their performance. Let’s look at how different materials impact the performance of welded and seamless pipes:

- Durability: Stainless steel and alloy steel are known for their exceptional durability. This makes them suitable for high-pressure applications. Carbon steel, while strong, may not be as durable in high-stress environments.

- Corrosion Resistance: If you’re dealing with corrosive substances, stainless steel is your best bet. It offers high resistance to rust and other forms of corrosion. Carbon steel, however, may require protective coatings to prevent corrosion.

- Flexibility: Seamless pipes generally offer better flexibility compared to welded ones, especially when made from materials like aluminum. This flexibility is crucial for applications requiring intricate bends and shapes.

- Cost: Material choice can significantly impact the cost. Carbon steel is usually less expensive than stainless steel or alloy steel. However, the long-term benefits of using a more durable and corrosion-resistant material can outweigh the initial cost.

Ultimately, the choice of material will depend on your specific needs and the conditions under which the pipes will be used. It’s a balancing act between cost, performance, and durability. So, next time you’re faced with the choice between welded and seamless pipes, remember that the material you choose can make all the difference!

Cost Comparison

When choosing between welded and seamless pipes, cost is always a key factor to consider. Both types of pipes have their own unique production processes, which significantly impact their prices. Additionally, the long-term costs associated with maintenance and durability also play a crucial role. Let’s dive into the cost comparison of welded and seamless pipes.

Production Costs

Producing welded pipes is generally less expensive than making seamless pipes. Why? The process of welding is less complex and doesn’t require specialized equipment. Here’s a closer look:

- Welded Pipes: These are made by rolling a flat steel plate and welding the edges together. This method is quick, efficient, and cost-effective.

- Seamless Pipes: These are manufactured by heating a solid steel billet and then piercing it to create a hollow tube. This process is more intricate and requires advanced machinery, making it more expensive.

To put it simply, if you’re on a tight budget, welded pipes might be the way to go. However, the initial savings may not tell the whole story. Let’s look at the long-term costs.

Long-term Costs

While welded pipes might save you money upfront, seamless pipes often offer greater longevity and durability, potentially saving you money in the long run. Here are some considerations:

- Durability: Seamless pipes don’t have a welded seam, which makes them less susceptible to corrosion and cracks. This means fewer repairs and replacements over time.

- Maintenance: Seamless pipes require less maintenance due to their uniform structure. Welded pipes, on the other hand, may need more frequent inspections and repairs at the welded joints.

- Performance: In high-pressure environments, seamless pipes are often preferred as they can withstand higher stress without failing.

Think of it like buying a pair of shoes. You could get the cheaper pair, but if they fall apart after a few wears, you haven’t really saved any money, have you? The same principle applies to pipes. In the long run, seamless pipes might end up being the more economical choice.

So, what’s the verdict? While welded pipes might be easier on the wallet initially, seamless pipes could save you more money over time. It’s all about balancing your immediate budget constraints with your long-term needs.

Performance Factors

Understanding the performance factors of welded and seamless pipes is essential. These factors determine the pipe’s suitability for various applications. Key aspects to consider include durability, strength, and corrosion resistance.

Durability

Welded pipes are generally less durable than seamless pipes. The welding process can create weak spots. These spots may reduce the pipe’s overall lifespan. Seamless pipes, with no welded joints, offer higher durability. Their uniform structure makes them more reliable under stress.

Strength

Seamless pipes typically have greater strength than welded pipes. The absence of a seam means fewer potential failure points. Welded pipes can be strong, but the weld can be a weak link. In high-pressure environments, seamless pipes often perform better. Their solid structure can withstand more pressure.

Corrosion Resistance

Corrosion resistance is crucial in many industries. Seamless pipes usually have better corrosion resistance. The uniformity of their structure reduces weak spots. Welded pipes may be more prone to corrosion at the weld seam. Proper material selection can improve resistance in welded pipes. But seamless pipes naturally offer better protection.

Applications And Suitability

When it comes to choosing between welded and seamless pipes, understanding their applications and suitability can make all the difference. While both types of pipes serve similar purposes, certain characteristics make one more suitable than the other for specific situations. In this section, we’ll delve into the various applications and their corresponding suitability, shedding light on industry-specific uses and environmental considerations.

Industry-specific Uses

Each industry has its own set of requirements when it comes to piping. Let’s explore where welded and seamless pipes find their home:

- Oil and Gas: Seamless pipes are the go-to choice for the oil and gas industry due to their strength and ability to withstand high pressure. Imagine the pipes as the backbone of a marathon runner; they need to be strong to support the journey.

- Automotive: Welded pipes often find their place in the automotive industry. They’re like the carefully tailored suit of a businessman – custom-fit and reliable for the job at hand.

- Construction: Both welded and seamless pipes are used in construction, but seamless pipes are favored for structural integrity. Think of them as the steadfast pillars holding up a grand coliseum.

Environmental Considerations

Choosing the right type of pipe also involves thinking about the environmental impact. Here’s how each type fares:

- Corrosion Resistance: Seamless pipes tend to be more resistant to corrosion. Picture a knight in shining armor; it’s all about durability in the face of harsh environments.

- Temperature Variations: Welded pipes are known for their ability to handle extreme temperatures, much like a trusty thermos keeping your coffee hot or cold.

- Sustainability: Welded pipes often have a slight edge in terms of sustainability since they can be made from recycled materials. It’s like giving a second life to your old, comfy jeans.

So, whether you’re building the next skyscraper or setting up a new oil rig, knowing the differences in applications and suitability between welded and seamless pipes can help you make the right choice. After all, the devil is in the details, isn’t it?

Credit: www.savree.com

Expert Recommendations

Experts often provide valuable insights on choosing between welded and seamless pipes. Each type has its own strengths and weaknesses. Understanding these can help make an informed decision.

Welded pipes are known for their cost-effectiveness. Seamless pipes, on the other hand, offer superior strength. This makes them ideal for high-pressure applications.

Choosing The Right Pipe

Choosing the right pipe depends on several factors. Budget, application, and required strength are key considerations. Welded pipes are typically cheaper. They are perfect for low-pressure applications.

Seamless pipes, though more expensive, provide higher durability. They are preferred for high-pressure environments. Consulting with an expert can help determine the best fit for specific needs.

Future Trends

The future of piping involves advanced materials and technologies. Experts predict a rise in the use of composite materials. These materials promise to offer greater strength and flexibility.

There is also growing interest in environmentally friendly piping solutions. Sustainable materials and manufacturing processes are gaining popularity. Staying updated with these trends can offer long-term benefits.

Credit: newzelindustries.com

Frequently Asked Questions

Is Seamless Pipe Stronger Than Welded?

Yes, seamless pipes are generally stronger than welded pipes. They have no weld seam, reducing the risk of weak points.

What Is The Difference Between Welded And Seamless Tubes?

Welded tubes have a seam from welding, while seamless tubes do not. Seamless tubes are stronger and more uniform.

What Does “seamless Pipe” Mean?

A seamless pipe is a pipe without any weld joints. It is made from a solid round steel billet, ensuring strength and durability. Seamless pipes are used in high-pressure applications.

Is Seamless Pipe More Expensive Than Welded?

Yes, seamless pipes are generally more expensive than welded pipes. Seamless pipes require more complex manufacturing processes.

Conclusion

Choosing between welded and seamless pipes depends on your specific needs. Seamless pipes offer strength and durability. Welded pipes provide cost efficiency and availability. Each type has its unique benefits. Consider the application requirements. Make an informed decision based on strength, cost, and availability.

Both welded and seamless pipes play crucial roles. Understanding their differences helps in making the right choice. This ensures optimal performance for your projects. Whether for construction or industry, knowing the pipe types matters.