Welding and forging are two essential metalworking processes. They both shape and join metals but in different ways.

Understanding the difference between welding and forging is crucial for choosing the right technique for your project. Welding involves fusing materials using heat, often with the help of a filler material. This process can join similar or different metals. On the other hand, forging shapes metal using compressive forces, typically by hammering or pressing.

This method enhances the metal’s strength and durability. By exploring both methods, you can determine which suits your needs better. This guide will help you understand the key differences and advantages of each technique, so you can make an informed decision for your next project.

Welding Basics

Welding is an essential process in metalworking. If you’ve ever seen sparks flying and wondered what’s going on, you’re not alone. Welding involves joining two pieces of metal together by melting them and adding a filler material to form a strong bond. It’s a bit like super-gluing, but for metal. Let’s dive into the different types of welding and techniques used in this fascinating process.

Types Of Welding

Welding isn’t one-size-fits-all. Different situations call for different types of welding. Here are the most common ones:

- MIG Welding – Also known as Gas Metal Arc Welding (GMAW). It’s great for beginners because it’s relatively easy to learn.

- TIG Welding – Also called Gas Tungsten Arc Welding (GTAW). It offers precision and is perfect for delicate work.

- Stick Welding – Officially known as Shielded Metal Arc Welding (SMAW). It’s versatile and can be used outdoors.

- Flux-Cored Arc Welding (FCAW) – Similar to MIG welding but uses a special wire that helps shield the weld from contaminants.

Common Welding Techniques

Welding isn’t just about knowing the types; it’s also about mastering the techniques. Here are some common ones:

- Butt Joint – Two pieces of metal are joined along a single edge. Think of it like clapping your hands together.

- Lap Joint – One piece of metal overlaps another. It’s like stacking two playing cards slightly on top of each other.

- T-joint – One piece of metal is perpendicular to another, forming a T shape. Imagine connecting two Lego pieces at a right angle.

- Corner Joint – Two pieces of metal are joined at the corner, forming an L shape. It’s like the corner of a picture frame.

Understanding these basics can help demystify welding. Whether you’re a hobbyist or looking to start a new career, knowing the types and techniques is the first step. So, grab your safety goggles, and let’s get welding!

Forging Basics

Have you ever wondered how blacksmiths in old movies create those stunning swords and tools? They use a process called forging. But what exactly is forging, and how does it differ from welding? Let’s dive into the basics of forging to get a clearer picture.

Types Of Forging

Forging is not a one-size-fits-all process. There are several types of forging, each with its own unique methods and applications. Here are some of the most common ones:

- Open-Die Forging: This type involves shaping the metal between multiple dies that do not enclose the workpiece. Think of it like a sculptor chiseling away to create a statue.

- Closed-Die Forging: Also known as impression-die forging, this method uses dies that cover the workpiece, forming it into the desired shape. Imagine pressing cookie dough into a mold to get perfectly shaped cookies.

- Seamless Rolled Ring Forging: This technique produces strong and durable rings by punching a hole in a thick, round piece of metal and then rolling it into a thin ring. It’s like making a donut from a solid piece of dough.

Common Forging Techniques

Now that we’ve covered the types, let’s explore some common techniques used in forging. Each technique has its own charm and utility, much like how different cooking methods bring out unique flavors in food.

- Hammering: The most iconic forging technique. The blacksmith heats the metal until it’s red-hot and then hammers it into shape. It’s as old-school as you can get and extremely satisfying to watch.

- Press Forging: This method uses a press to exert a continuous force on the metal. It’s like slowly squeezing toothpaste out of a tube, but with a lot more power and precision.

- Roll Forging: In this technique, metal is passed through a series of rolls that gradually shape it. Imagine rolling out dough with a rolling pin to get it just right.

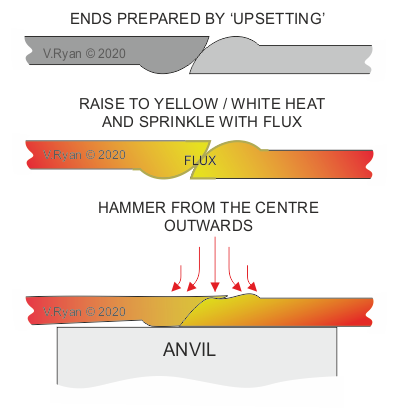

- Upset Forging: This technique increases the diameter of the workpiece by compressing its length. Picture making a thick pancake by pushing down on a ball of dough.

Forging is an ancient craft that has evolved significantly over the years. Whether it’s hammering, pressing, or rolling, each technique has its own unique appeal and purpose.

Materials Used

Understanding the materials used in welding and forging is important. These processes use different materials, which affects their applications and outcomes. Let’s explore these materials in detail.

Welding Materials

Welding often uses metals like steel, aluminum, and stainless steel. These materials are chosen for their ability to melt and fuse together. Welders also use filler materials to join metal pieces. These fillers match the type of metal being welded. In some cases, welding can also use materials like copper and nickel. Each material has unique properties that affect the welding process.

Forging Materials

Forging primarily uses metals such as steel, iron, and aluminum. These materials are heated and shaped under high pressure. Forged parts are known for their strength and durability. The choice of material depends on the desired properties of the final product. Other materials used in forging include brass, titanium, and copper. Each material offers different benefits in terms of strength and flexibility.

Processes Involved

Understanding the processes involved in welding and forging is key to grasping how these two methods differ. While both techniques aim to join or shape metals, they do so through distinct procedures. Let’s dive into the steps involved in each process.

Welding Process Steps

Welding involves joining two pieces of metal by melting them together. Here’s how it’s done:

- Preparation: Clean the metal surfaces to remove rust, oil, and dirt. This ensures a strong bond.

- Alignment: Align the metal pieces properly. Use clamps to hold them in place.

- Electrode Selection: Choose the right welding electrode. The electrode type depends on the metal and the welding method.

- Welding: Use a welding machine to melt the metal along the joint. The heat melts the metal and the electrode, forming a pool of molten metal.

- Cooling: Allow the joint to cool down. This solidifies the molten metal, creating a strong bond.

- Finishing: Remove any slag or excess metal. Smooth the weld if necessary.

Forging Process Steps

Forging, on the other hand, shapes metal through the application of force. Here’s a simplified look at the process:

- Heating: Heat the metal until it becomes red-hot. The temperature must be high enough to make the metal malleable.

- Positioning: Place the heated metal on an anvil or forge.

- Shaping: Hammer the metal into the desired shape. This can be done manually or with a power hammer.

- Cooling: Allow the shaped metal to cool down slowly. This helps retain its new shape.

- Finishing: Clean the forged piece. Additional machining may be required to achieve precision.

By looking at these steps, you can see how welding and forging employ different methods to achieve their goals. Welding is about joining, while forging is about shaping. Both processes have their own unique set of steps and tools, making them suited for different applications.

Applications

Welding and forging are vital processes in various industries. Each technique has unique applications. Understanding these applications can help determine the best method for a specific task.

Welding Applications

Welding is essential in construction, automotive, and aerospace industries. It joins metal parts to build structures. For instance, welding is used in the construction of bridges and buildings. In the automotive industry, welding is crucial for assembling car bodies. Aerospace applications include welding aircraft components for durability and safety.

Forging Applications

Forging finds its place in manufacturing and tool production. It shapes metals through compressive forces. Forging is common in creating gears, shafts, and bolts. These components are vital in machinery and engines. In the tool industry, forging produces durable hammers, wrenches, and other hand tools.

Credit: www.redriver.team

Advantages And Disadvantages

Understanding the advantages and disadvantages of welding and forging is crucial. It helps you choose the right technique for your projects. Both methods have their unique benefits and drawbacks. Let’s dive into these aspects to get a clearer picture.

Pros And Cons Of Welding

Welding has several advantages. It creates strong joints, making it ideal for construction. The process is quick, reducing production time. Welding also allows joining different metals together.

But welding has its downsides. It requires skilled labor, which can be costly. The process also exposes workers to harmful fumes and intense heat. Welding may lead to metal distortions if not done correctly.

Pros And Cons Of Forging

Forging also comes with its own set of benefits. It produces parts with excellent mechanical properties. The process enhances the strength and durability of the metal. Forged parts are less likely to fail under stress.

On the flip side, forging has disadvantages too. It generally requires expensive equipment. The process can be time-consuming and labor-intensive. Forging also limits the shapes and sizes of the parts that can be produced.

Choosing Between Welding And Forging

Choosing between welding and forging can be challenging. Both methods have unique benefits and serve different purposes. Understanding these differences helps you make informed decisions for your projects. Below, we explore the key factors to consider and industry examples to guide your choice.

Factors To Consider

First, think about the material type. Welding is better for joining similar metals. Forging works well with a wide range of metals. Next, consider the strength requirement. Forged parts are usually stronger than welded ones. This is because forging compresses the metal, making it denser.

Another factor is the complexity of the shape. Welding is ideal for complex designs. It allows for more freedom in shaping the metal. On the other hand, forging often requires simpler shapes. Cost also plays a role. Welding can be cheaper for small projects. Forging is cost-effective for larger batches.

Industry Examples

The automotive industry uses both techniques. Welding is common for car bodies and frames. It allows for precise and strong joins. Forging is used for parts like crankshafts and gears. These parts need high strength and durability.

In the aerospace industry, welding is often used for assembling aircraft parts. It ensures a strong bond between metal sheets. Forging is preferred for critical components like turbine blades. These parts must withstand extreme conditions.

Construction projects also benefit from both methods. Welding is used for steel structures and pipelines. It ensures a secure and lasting connection. Forging is used for tools and fasteners. These must endure high stress and repeated use.

Credit: technologystudent.com

Future Trends

As technology continues to advance, both welding and forging are evolving at a rapid pace. These changes are driving the industries forward, improving efficiency, precision, and overall quality. Let’s dive into what the future holds for these two essential manufacturing processes.

Innovations In Welding

Welding is seeing some exciting innovations that promise to transform the industry. One of the most significant trends is the integration of automation and robotics. Imagine robots taking over repetitive welding tasks, ensuring precision and consistency. This not only speeds up production but also reduces the margin for human error.

Another notable trend is the development of advanced welding materials. These materials can withstand higher temperatures and pressures, making them ideal for use in extreme environments like aerospace and underwater construction.

| Innovation | Benefit |

|---|---|

| Automation and Robotics | Increased precision and efficiency |

| Advanced Welding Materials | Enhanced durability in extreme conditions |

Moreover, 3D printing is starting to play a role in welding. This technology can create complex structures layer by layer, offering unprecedented design flexibility. It’s like giving the welder a magic wand!

Advancements In Forging

On the forging front, there are some fascinating advancements as well. For starters, computer-aided design (CAD) is revolutionizing the way forging dies are created. With CAD, engineers can design more intricate and precise dies, leading to better-quality forged products.

Another game-changer is the use of new alloys. These innovative materials are stronger and lighter, perfect for industries like automotive and aerospace where weight and strength are critical.

- Computer-Aided Design (CAD)

- New Alloys

Furthermore, induction heating is becoming more popular in forging. This method uses electromagnetic fields to heat metals, which is faster and more energy-efficient compared to traditional methods. Plus, it reduces the environmental impact—who doesn’t love a green technology?

Lastly, the trend of digital twins is making waves. This technology creates a virtual replica of the forging process, allowing for real-time monitoring and optimization. It’s like having a crystal ball that predicts and improves outcomes!

In conclusion, the future of welding and forging is bright, with new technologies pushing the boundaries of what’s possible. These advancements not only enhance the quality and efficiency of the processes but also open up new possibilities for innovation. So, whether you’re a professional in the field or just curious, keep an eye on these trends—they’re set to reshape the industry!

Credit: www.facebook.com

Frequently Asked Questions

What Is The Difference Between Forging And Welding?

Forging shapes metal using compressive forces, often with heat. Welding joins metal pieces by melting and fusing them together.

What Is The Difference Between Welded And Forged?

Welded materials are joined by melting and fusing parts together. Forged materials are shaped under high pressure without melting.

Can Forgings Be Welded?

Yes, forgings can be welded. Proper techniques and materials ensure strong and durable welds. Consult with welding experts for best results.

Are Welders Like Blacksmiths?

Welders and blacksmiths both work with metal, but their methods and tools differ. Welders join metal pieces using heat. Blacksmiths shape metal using hammers and anvils.

Conclusion

Welding and forging both shape metal but in different ways. Welding joins pieces by melting them. Forging shapes metal using heat and pressure. Both methods have unique applications and benefits. Choosing the right method depends on your project’s needs. Consider the material, strength, and purpose.

Understanding these differences helps in making informed decisions. Whether building, repairing, or manufacturing, knowing the right technique is crucial. Thank you for reading!