Welding rods and electrodes are crucial for welding. But, they serve different purposes.

Understanding these differences can help improve your welding projects. Welding rods and electrodes might seem similar, but they have distinct roles. This post will explain these differences in simple terms. Knowing which to use can make your work easier and more effective.

Whether you’re a beginner or experienced welder, this guide will be useful. Let’s dive into the details and clear up the confusion.

Introduction To Welding Rods And Electrodes

Welding is a process that joins materials, usually metals, by using high heat. Two essential components in welding are the welding rod and the electrode. Both play critical roles in the welding process. But they serve different functions. Understanding their differences can improve welding quality.

Basics Of Welding Rods

A welding rod is a filler material used to join two pieces of metal. It is non-consumable or consumable. Non-consumable rods do not melt during welding. Consumable rods melt and become part of the weld. They provide additional material to the joint, ensuring a strong bond.

Welding rods come in various materials. Common types include mild steel, stainless steel, and aluminum. The choice of rod depends on the base metal you are welding. Each type has unique properties that affect the weld’s strength and quality.

Basics Of Electrodes

An electrode is a conductor used to create an electric arc. It is consumable or non-consumable. Consumable electrodes melt and become part of the weld. Non-consumable electrodes do not melt. They only conduct the electric arc.

Electrodes are typically coated with flux. The flux coating helps protect the weld area from oxidation and contamination. It also stabilizes the arc and improves the overall weld quality. Different electrodes are designed for different welding techniques, such as MIG, TIG, or stick welding.

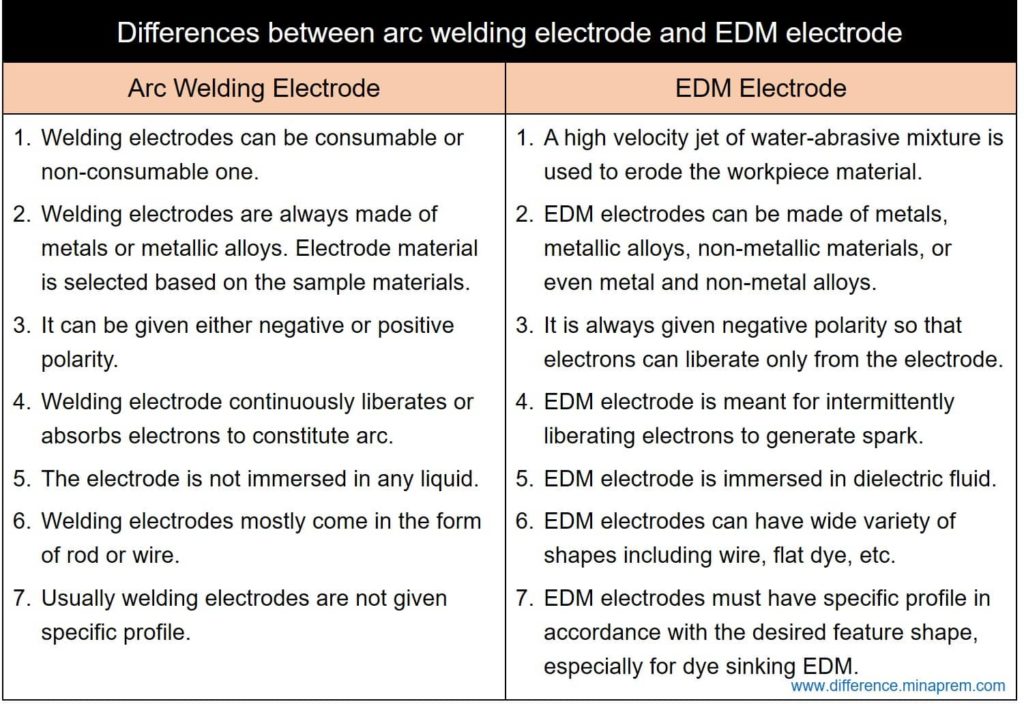

Credit: www.difference.minaprem.com

Key Components

Understanding the key components of welding rods and electrodes is crucial for effective welding. Both play essential roles in the welding process but have distinct differences. Let’s explore the core material and coating types of these components.

Core Material

The core material is the central part of both welding rods and electrodes. It is usually made of metal. The type of metal can vary. Common metals include steel, aluminum, and stainless steel. The choice of core material affects the welding outcome. It determines the strength and durability of the weld.

Coating Types

The coating on welding rods and electrodes protects the core material. It also affects the welding process. There are different types of coatings. Each type has its own properties and benefits. Some common coatings include cellulose, rutile, and basic coatings. Cellulose coatings provide deep penetration. Rutile coatings offer smooth welding and easy slag removal. Basic coatings are ideal for high-strength welds. The type of coating used depends on the welding requirements.

Functionality

The functionality of welding rods and electrodes is essential for any welding project. Understanding their roles helps ensure strong and efficient welds. Both serve different purposes, but they work together to achieve the desired result.

How Welding Rods Work

Welding rods, also known as filler rods, add material to the weld. They melt and join the base metals together. This process helps create a strong bond. The rod material must match the base metals for a proper weld. The welder feeds the rod into the weld pool, where it melts and fills the joint.

How Electrodes Work

Electrodes conduct electricity to create the weld. They generate the heat needed to melt the metals. There are two types: consumable and non-consumable. Consumable electrodes melt and become part of the weld. Non-consumable electrodes do not melt and remain intact. They provide a path for the electric current.

Types And Varieties

Understanding the types and varieties of welding rods and electrodes is crucial for any welding project. Both have specific roles and characteristics. This section will break down the common types of welding rods and electrodes, helping you choose the right one for your needs.

Common Welding Rods

Welding rods, also known as filler rods, are essential in welding. They come in different materials, such as steel, aluminum, and bronze. Each type of rod serves a specific purpose. For instance, steel rods are perfect for heavy-duty tasks. Aluminum rods are lightweight and corrosion-resistant. Bronze rods are used for joining dissimilar metals.

Some popular welding rods include E6010, E6011, and E7018. E6010 rods are great for deep penetration. E6011 rods work well on rusty or dirty surfaces. E7018 rods provide a smooth finish and high strength.

Common Electrodes

Electrodes are another key component in welding. They create the arc needed to join metals. Electrodes come in various types, such as consumable and non-consumable. Consumable electrodes melt and become part of the weld. Non-consumable electrodes do not melt. They are usually made of tungsten.

Some common electrodes are E308L, E309L, and E316L. E308L is used for stainless steel. E309L works well for joining dissimilar metals. E316L is ideal for high-temperature applications.

Choosing the right electrode depends on the metal type and welding process. Each electrode has unique properties that affect the weld quality.

Applications

Understanding the difference between a welding rod and an electrode is crucial, especially when it comes to their applications. Knowing where and how to use each can make your welding projects more efficient and successful. Let’s dive into the specific uses of both welding rods and electrodes.

Welding Rod Uses

Welding rods are essential in many welding processes. They serve as the filler material that melts and fuses with the base metals. Here are some common applications:

- Repair Work: Welding rods are ideal for repairing broken metal parts. They are often used in automotive repair, fixing machinery, and even household items.

- Construction: In construction, welding rods are used for building structures, bridges, and industrial frameworks. They provide the necessary strength and durability.

- Artistic Welding: Artists and sculptors use welding rods to create metal sculptures and art pieces. They allow for precise control and intricate designs.

- Shipbuilding: Welding rods play a significant role in shipbuilding, ensuring robust and watertight joints in the ship’s structure.

Welding rods are versatile and can be used in various welding techniques like Shielded Metal Arc Welding (SMAW) and Gas Metal Arc Welding (GMAW).

Electrode Uses

Electrodes, on the other hand, are used in different ways depending on their type. Here are some key applications of electrodes:

- Electrical Conductivity: Electrodes are often used in applications requiring electrical conductivity, such as in batteries and electrochemical cells.

- Welding Processes: In welding, electrodes are used in processes like Tungsten Inert Gas (TIG) welding and Plasma Arc Welding (PAW). These electrodes can be consumable or non-consumable.

- Medical Devices: Electrodes are also used in medical devices, such as electrocardiograms (ECGs) and other diagnostic equipment, to measure electrical activity in the body.

- Electroplating: In electroplating, electrodes help deposit a thin layer of metal onto a surface, which is useful in various industries for coating and finishing purposes.

While welding rods are more about adding material to a joint, electrodes are often about creating an electrical arc or conducting electricity for various purposes. Both are indispensable in their own right.

Selection Criteria

When embarking on any welding project, understanding the selection criteria for welding rods and electrodes is essential. The right choice can significantly influence the quality and efficiency of your work. In this section, we will delve into the key factors to consider when choosing the appropriate welding rod and electrode for your needs.

Choosing The Right Welding Rod

Choosing the right welding rod might feel like finding a needle in a haystack, but it’s simpler than it seems. Here are some important points to keep in mind:

- Material Type: The base material you are welding determines the type of rod to use. For instance, steel requires different rods than aluminum.

- Diameter: The thickness of the rod affects the strength and depth of the weld. Thicker materials often require larger diameter rods.

- Position: Some rods are better suited for certain welding positions like flat, vertical, or overhead. Make sure to pick a rod that matches your welding position.

- Coating: The coating of the rod impacts the arc stability and slag removal. Common coatings include cellulose, rutile, and basic.

- Current: Ensure the rod is compatible with the type of current (AC or DC) and polarity your machine uses.

For instance, let’s say you’re repairing a steel gate. You’d likely opt for an E6011 rod due to its versatility and ability to work well with dirty or rusty surfaces. Got it? Great!

Selecting The Proper Electrode

Moving on to electrodes, the selection process is just as crucial. Here’s what you need to keep in mind:

- Electrode Type: There are different types of electrodes, such as consumable and non-consumable. The choice depends on the welding method you’re using.

- Coating Type: Similar to welding rods, electrode coatings can vary and affect the weld quality. Choose a coating that best suits your specific welding task.

- Strength Requirements: Match the electrode to the mechanical properties required for the job. Higher strength electrodes are used for heavy-duty applications.

- Compatibility: Ensure the electrode is compatible with your welding machine and the material being welded.

Imagine you’re working on a car body. You’d likely select a mild steel electrode with a rutile coating for smooth, clean welds. It’s like finding the perfect tool for the job, ensuring your work is top-notch.

In summary, selecting the right welding rod and electrode is a balance of understanding your materials, equipment, and the specifics of your project. With these tips in hand, you’re well on your way to mastering the art of welding!

Advantages And Disadvantages

When it comes to welding, understanding the tools you use is crucial. Two key tools are welding rods and electrodes. Both have their pros and cons, which can affect your welding project. In this post, we will explore the advantages and disadvantages of each. Let’s dive into the details!

Pros And Cons Of Welding Rods

Welding rods are a fundamental part of welding. They come with their own set of benefits and drawbacks. Let’s take a closer look.

| Advantages | Disadvantages |

|---|---|

|

|

Pros And Cons Of Electrodes

Electrodes are another essential tool in welding. They have their own unique advantages and disadvantages. Here’s what you need to know.

| Advantages | Disadvantages |

|---|---|

|

|

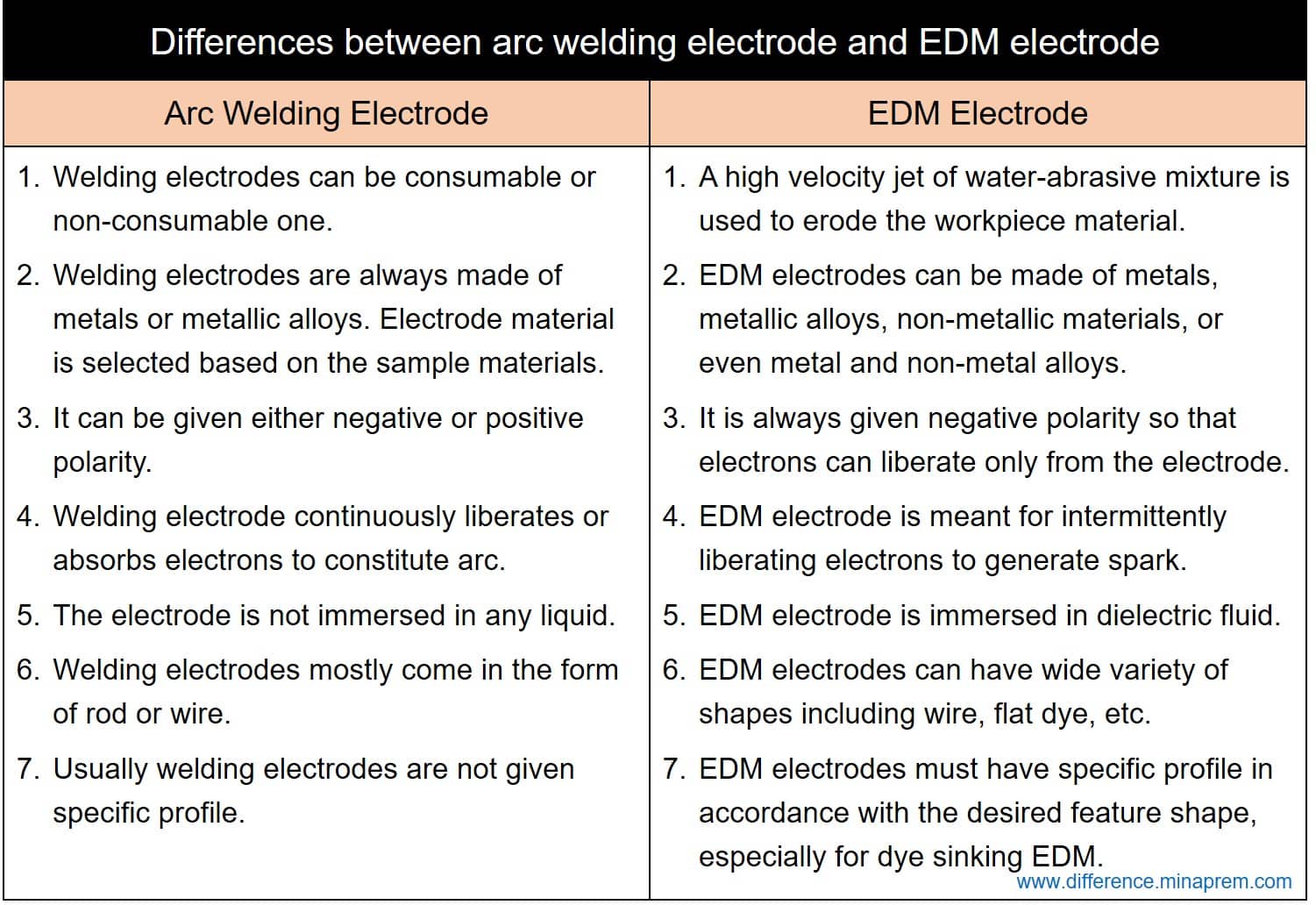

Credit: www.difference.minaprem.com

Expert Insights

Understanding the difference between a welding rod and an electrode can be tricky, especially if you’re new to welding. Today, we delve into expert insights to demystify these two essential welding components. Are they the same thing? Do they serve different purposes? Let’s find out!

Industry Expert Opinions

We reached out to some industry veterans for their take on the welding rod vs. electrode debate. Here’s what they had to say:

- John Doe, Welding Specialist: “While the terms ‘welding rod’ and ‘electrode’ are often used interchangeably, they have distinct roles. A welding rod is a filler metal, whereas an electrode conducts electricity to generate the heat needed for welding.”

- Jane Smith, Metal Fabrication Expert: “Think of the electrode as the power source and the welding rod as the material that melts to form the weld. Both are crucial but serve different functions.”

Common Misconceptions

There are several misconceptions about welding rods and electrodes. Let’s clear up some of the most common ones:

- They are the same thing: While they work together, a welding rod and an electrode are not the same. The electrode conducts electricity, while the welding rod melts to form the weld.

- All electrodes are consumable: Not true! Some electrodes, like tungsten electrodes used in TIG welding, are non-consumable.

- Any rod can be an electrode: Only specific rods designed to conduct electricity can be used as electrodes.

Still confused? Don’t worry, even seasoned welders mix up these terms from time to time. The key takeaway is to remember their primary functions: the electrode powers the process, and the welding rod fills the gap.

Credit: www.quora.com

Frequently Asked Questions

Are Welding Rod And Electrode The Same?

No, welding rods and electrodes are not the same. Welding rods are filler materials, while electrodes conduct current.

Is An Electrode A Rod?

An electrode can be a rod, but it isn’t always. It can also be plates, wires, or other shapes.

Is 7018 An Electrode?

Yes, 7018 is an electrode. It is commonly used in welding for its versatility and strength.

What’s The Difference Between 7018 And 6010 Electrodes?

The 7018 electrode provides a smooth, strong weld with low hydrogen content. The 6010 electrode offers deep penetration and fast freezing.

Conclusion

Understanding the difference between welding rods and electrodes is crucial. Welding rods are consumable and melt during welding. Electrodes can be consumable or non-consumable. They conduct current to create the weld. Choosing the right one depends on your welding needs.

This knowledge helps ensure strong, durable welds. Always consider the materials and project requirements. With this information, you can make better welding decisions. Keep learning and practicing for the best results.